Installation instruc tio ns – Poison Spyder JK REAR CRUSHER FLARES User Manual

Page 2

INSTALLATION INSTRUC

TIO

NS

Poison Spyder Customs • JK REAR CRUSHER FLARES INSTALL

Page 2

©2010 POISON SPYDER CUSTOMS, INC. • 951-849-5911 • WWW.POISONSPYDER.COM

Crusher Flares come as unpainted, bare steel or

aluminum. You will want to either powder coat

or paint prior to final installation, however it is

very important to PRE-INSTALL the unpainted

product first, following these instructions,

BEFORE painting or powder coating any of the

components! This will ensure that all parts are

correct and any incidental trimming or drilling will

have been done prior to coating. Also, it will give

you a practice run to familiarize yourself with the

process, to lessen the likelihood of damaging the

finish during final installation.

IMPORTANT: Poison Spyder Customs, Inc. is

NOT RESPONSIBLE for paint or powder coating

costs, damage to paint or powder coating, or

costs associated with inadvertently painting or

powder coating components that are defective

or were shipped or assembled in error. It is the

customer’s responsibility to pre-install and verify

that all parts are correct prior to paint or powder

coat.

NOTE ON STEEL CRUSHER FLARES: The

small space where the top plate meets the outer

tube is not continuously welded, and therefore

not completely sealed against moisture. Please

make sure that paint or powder coat are applied

heavily in this area, to seal the seam up against

water intrusion and rust forming (this is not

a issue on aluminum Crusher Flares). Thick

coatings such as spray-on bedliner material will

also seal it up if applied correctly. If your paint

or coating is very thin or not thoroughly applied

to this area, apply a bead of silicone sealant to

the seam on the underside of the top plate where

it meets the tubing. Rubberized undercoating

works for this as well.

INSTALLATION PROCEDURE

The following procedure is for preparation and

installation of the JK Crusher Flare on one side of

the Jeep. Once complete, repeat the procedure

for the other side.

1. Park vehicle on a level surface and set the

emergency brake. You will want to wear eye

protection beyond this point in time.

2. Remove the stock flare and inner fender.

You may need a flat screwdriver or special

tool as shown in Figure 1 to remove some of

the plastic retainer clips.

3. Apply masking tape to the Jeep body along

the outside of the fender recess, to protect

the paint while installing the Crusher Flare.

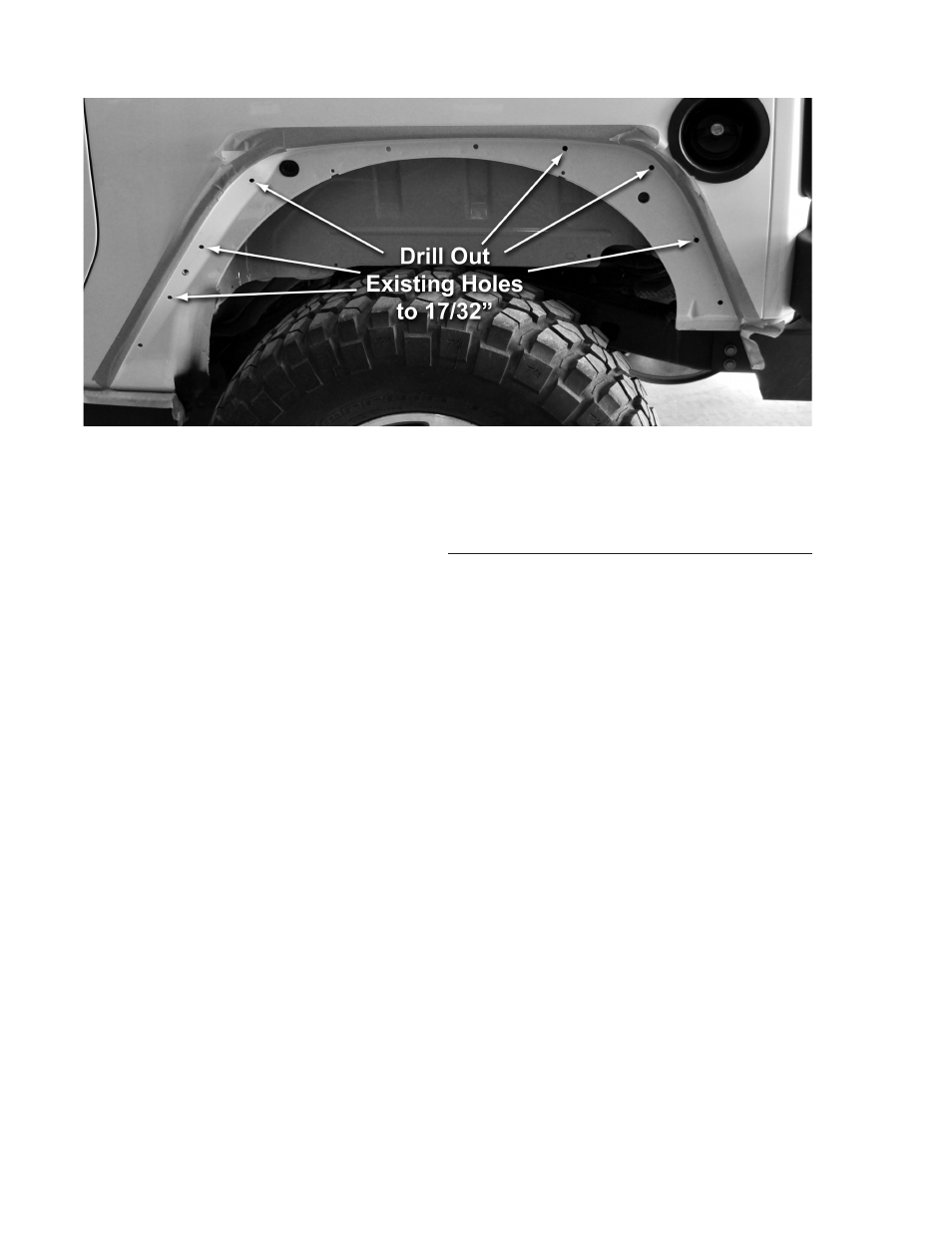

4. Re-drill the stock holes indicated in Figure

2, to 17/32”. It is VERY IMPORTANT to be

extremely careful when drilling these holes.

Take extra care to ensure that the drill bit

is exactly perpendicular to the sheetmetal,

as it may “walk” and dislocate the resulting

hole. Also be careful when drilling, as the

thin sheetmetal may want to catch on the bit

and deform it, making the subsequent nut-

sert installation more difficult.

FIGURE 2