Installation notes - impeller, Installation notes – impeller, Caution – Hale 80FC User Manual

Page 96

❑ Corrective Maintenance

96

Pump Ends

p/n: 029-0020-61-0

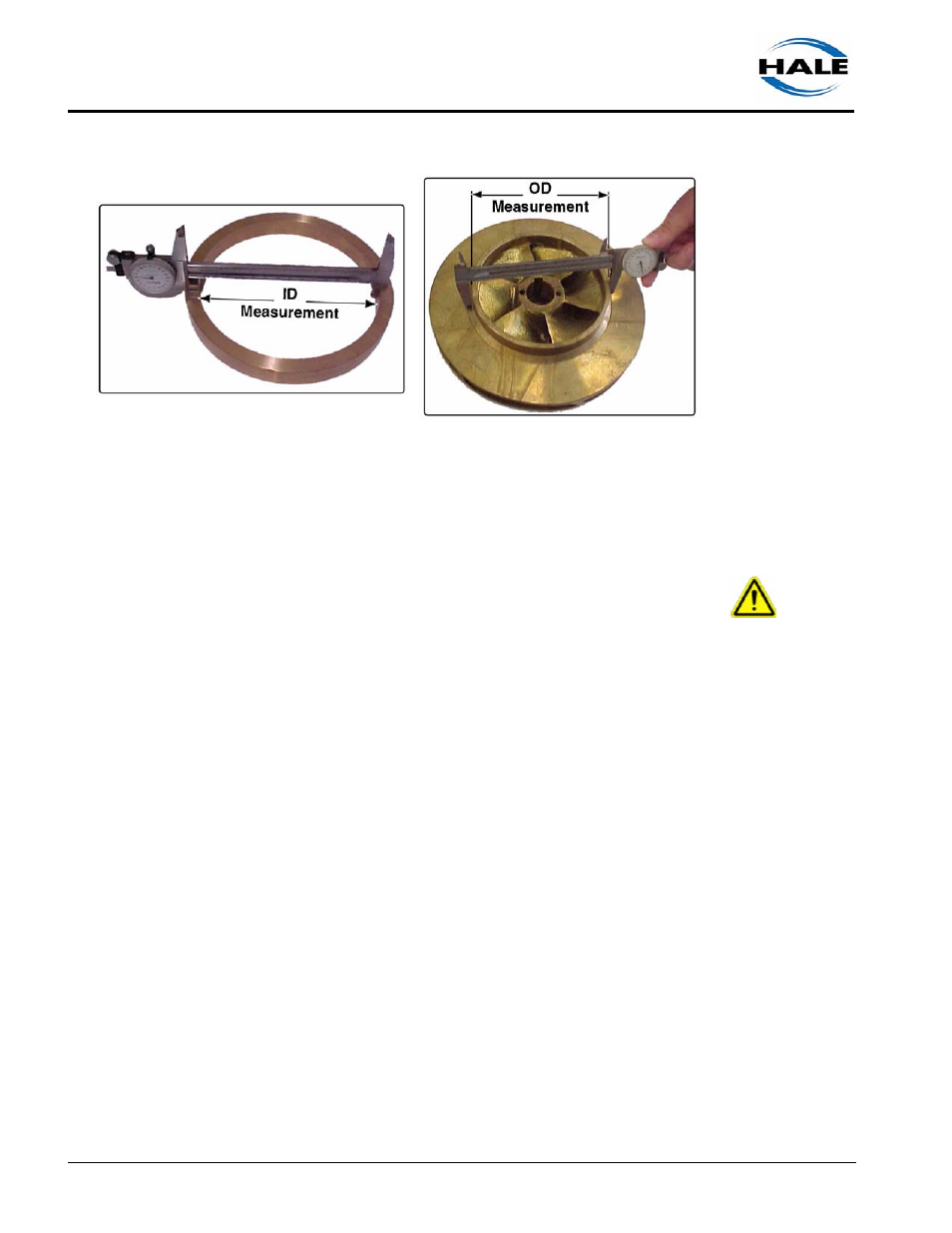

Figure 6a-6: Clearance Ring and Impeller ID / OD Measurement

The impeller hub diameter can be cut (turned down) and “undersized” clear-

ance rings can be ordered to compensate for a new impeller diameter. Contact

Customer Service at Hale Products at 610-825-6300.

CAUTION !

WHEN TURNING IMPELLERS TO FIT UNDERSIZED RINGS, CAUTION MUST BE

EXERCISED TO ENSURE THAT THE SEAL RING SURFACE RUNS TRUE WITH

THE BORE TO WITHIN 0.002” (0.051MM).

Installation Notes – Impeller

Follow the preceding steps in the reverse order, while paying attention to the fol-

lowing:

❑

Review heading 6a.1 “General Preparation” on page 85.

❑

Review heading 6a.1 “General Preparation” on page 85.

❑

Align the impeller to the keyway, then slide onto the pump shaft.

❑

For 30 FS series pumps - apply Loctite to the threads, then instal the 3/4”-

16 nut and washer and torque to approximately 104 ft.-lbs. (141 N-m)

❑

For all other pump models

●

Apply Loctite to the threads, then install the impeller nut and torque to 210

ft.-lbs. (285 N-m) minimum.

●

Continue tightening the impeller nut until the cotter pin can be installed to

lock the nut in place.

●

Install cotter pin and bend over the ends.