6b mechanical seal assembly, 6b.1 removing the seal, Figure 6b-1: typical mechanical seal assembly – Hale 80FC User Manual

Page 111: See section 6a

111

Mechanical Seal Replacement

Hale Products, Inc., March 2007, Rev-C

M e ch an ic al Se al Re p la ce me n t

❑

6b Mechanical Seal Assembly

IMPORTANT !

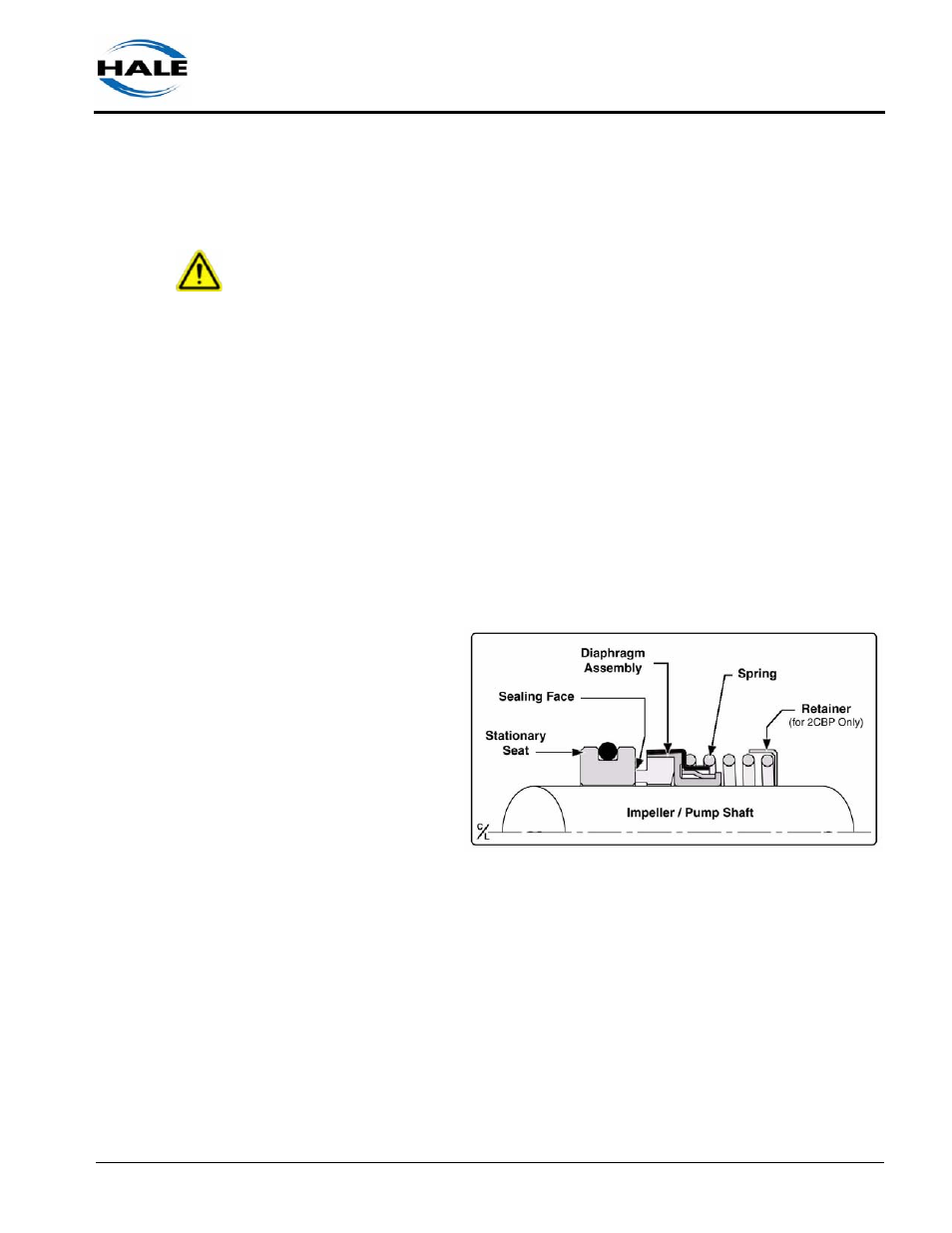

IF WATER LEAKAGE FROM THE DRAIN HOLE IN THE VOLUTE IS NOTICED, THE

IMPELLER MUST BE REMOVED AND THE MECHANICAL SEAL MUST BE

INSPECTED. (SEE FIGURE 6B-1: “TYPICAL MECHANICAL SEAL ASSEMBLY.”)

WHENEVER A MECHANICAL SEAL IS REMOVED, IT MUST BE REPLACED WITH A

“NEW” SEAL.

Before the mechanical seal can be replaced, the pump volute (pump body) and impel-

ler must be removed. Follow the instructions for removal and installation the volute and

impeller, based on your pump model, as detailed in the standard the Installation, Oper-

ation and Service Maintenance Manual provided with your pump.

6B.1

REMOVING THE SEAL

To expose the

mechanical seal, first

remove the:

❑

Pump suction

head, if included.

❑

Impeller - see

heading “Impeller”

on page 85.

1.

From within the

pump head, and

using two jaw-type

puller tools (hook-

type), spaced 180° apart, reach in and pry (pull) the seal ring from the pump

shaft.

Note: On pump models CBP and 2CBP first remove the spring retainer. (See Figure

6b-1: “Typical Mechanical Seal Assembly.”)

2.

Place two hook-type tools or two small screw drivers, 180° apart, between

the diaphragm assembly and the stationary sealing face. Using steady,

gentle pressure, pry the diaphragm assembly from the shaft.

3.

Slide the short end of a 3/32” or 7/74” (2.5 mm - 3.0 mm) hex key between

the back side of the pump head and the pump shaft.

Figure 6b-1: Typical Mechanical Seal Assembly