Insufficient pressure, Remote control difficult to operate – Hale 80FC User Manual

Page 74

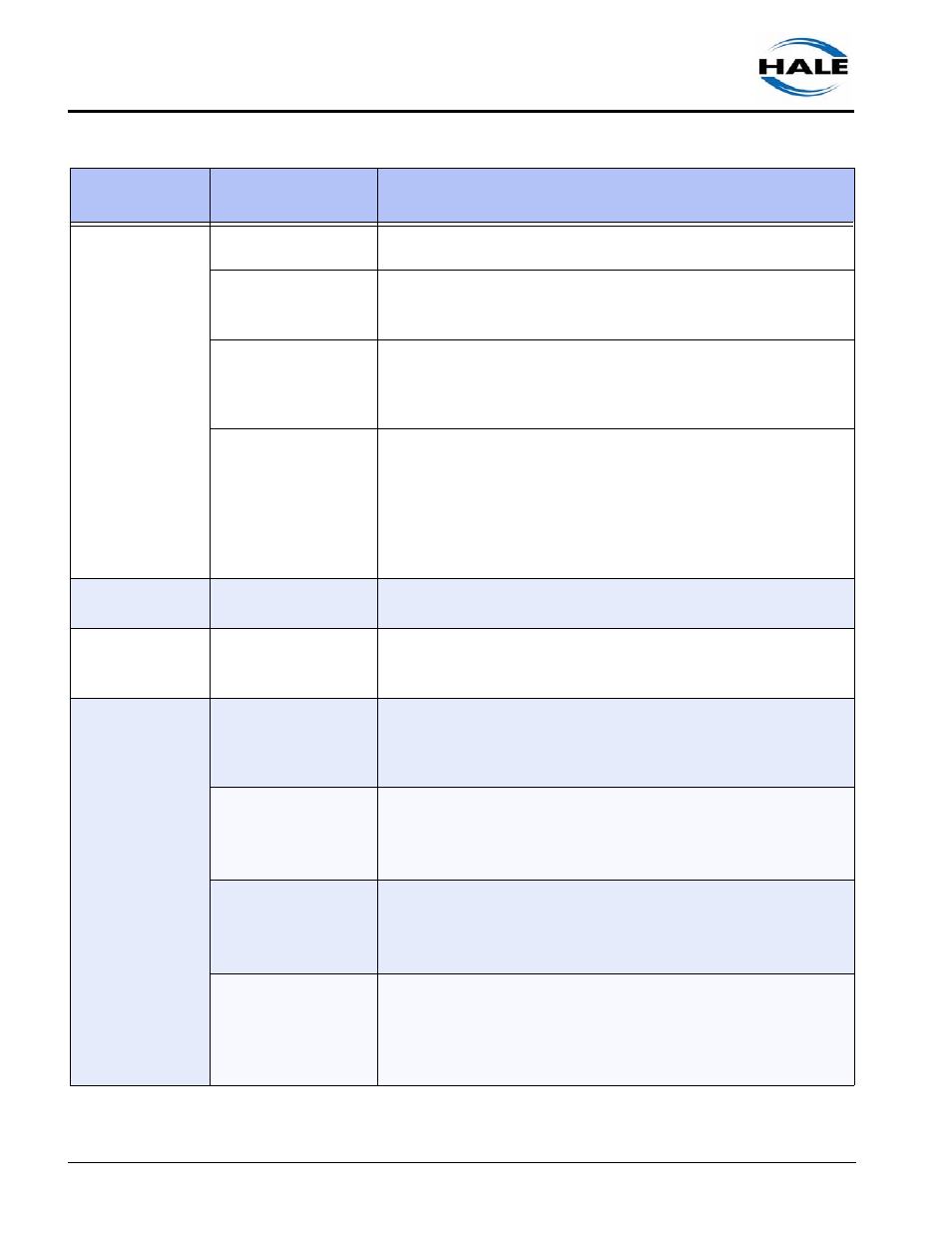

❑ Troubleshooting

74

Pump Ends

p/n: 029-0020-61-0

Insufficient Pump

Capacity -

continued.

Air leaks.

• See heading “Air leaks.” under condition “ Pump Loses Prime or

Will Not Prime” on page 73.

Partial collapse of the

lining in a suction hose.

• Damage to the outer lining may allow air between the outer and

inner linings causing a partial collapse.

• Replace hose and retest.

Engine governor set

incorrectly.

• If the engine governor is set too LOW (pressure), when on auto-

matic, engine speed decelerates before the desired pressure is

achieved.

• Reset governor per manufacturer’s procedures.

Truck transmission in

wrong gear or clutch is

slipping.

• Recheck the pumping procedures for the recommended transmis-

sion or gear range - review Section “Pumping Operations,” begin-

ning on page 47.

• Use a mechanical speed counter on the pump panel to check

speed against possible clutch or transmission slippage or inaccu-

rate tachometer.

• Check truck manual for proper speed counter ratio.

Insufficient Pres-

sure.

Insufficient engine

power.

• See previous heading “Insufficient Pump Capacity.” on page 73.

Remote Control

Difficult to Oper-

ate.

Lack of lubrication.

• Lubricate the remote control linkages and collar with oil. For lubri-

cant recommendations, see “Appendix C1: Lube and Sealant

Specifications” on page 139.

Engine Speeds

Too HIGH for

Required Capac-

ity or Pressure.

Chart continued on

next page.

Truck transmission in

wrong gear or range.

• Recheck the pumping procedures for the recommended transmis-

sion or gear range - review Section 3 “Basic Operation,” beginning

on page 45.

• Check truck manual for proper speed counter ratio.

Lift too high, suction

hose too small.

• Higher than normal lift (10 ft. / 3.1m) causes higher engine speeds,

high vacuum and rough operation.

• Use larger suction hose.

• Move the pump closer to the water source.

Faulty suction hose.

• Inner lining of suction hose may collapse when drafting and is usu-

ally undetectable.

• Try a different suction hose on the same pump.

• Test for comparison against original hose.

Blockage at suction

hose entry.

• Clean suction hose strainer of obstruction. Also see Section 4 Pre-

ventive Maintenance, heading “Intake Strainers” on page 60.

• Follow recommended practices for laying suction hose.

• Keep off the bottom of the fluid supply by at least 2’ (0.6 meters)

below the surface of the fluid.

Condition

Possible

Cause

Suggested Corrective Action

Figure 5-2: Troubleshooting Chart