Pumping operations, Figure 3-1: typical portable pump installation – Hale 80FC User Manual

Page 47

47

Pump Ends

p/n: 029-0020-61-0

O p er atio n

❑

❑

Engine battery ELECTROLYTE level

(not required for live sealed high performance-type batteries).

❑

Pump, gearbox and pedestal OIL level, if supplied.

Pumping Operations

1.

Position the skid or trailer as close to the water source as practical. Pumps

smaller than 1,500 GPM (5,678 LPM) can draw 100% of rated capacity with

less than 10 feet (3.05 meters) vertical lift and 20 feet (6 meters) of suction

hose. Pumps smaller than 3,000 GPM (11,356 LPM) have six (6) feet (1.8

meter) vertical lift capability.

As the vertical lift increases, pump capacity is reduced. (See Figure F-3:

“Lift Loss from Elevation” on page 147.) Also see heading “Draft Operation

Limiting Factors” on page 49.

2.

For trailers, apply the brakes, chock the wheels and lower the trailer jacking

stabilizers to level and support the trailer. See WARNING ! note on page

45.

3.

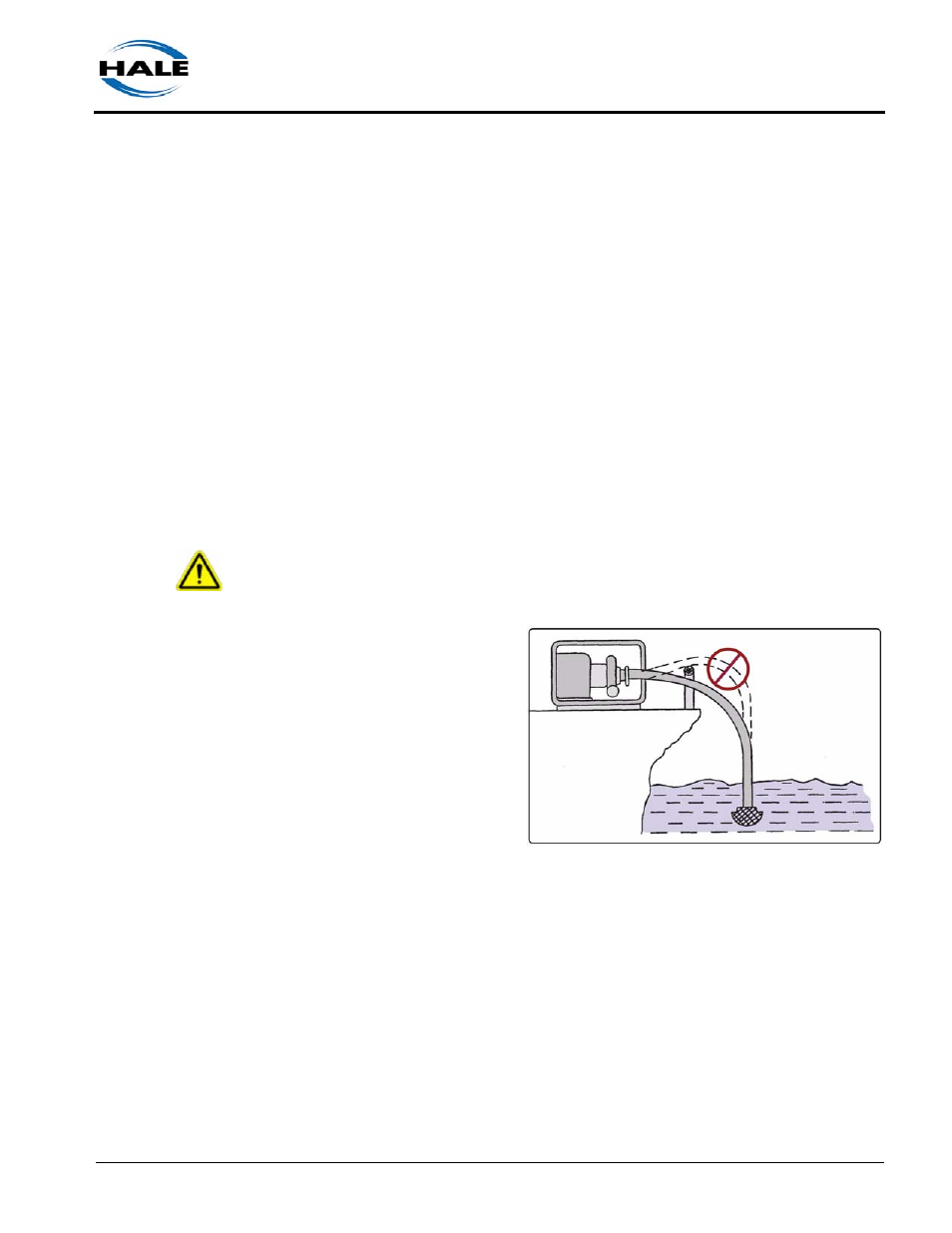

Attach a suction line to the

pump, installing a strainer

on the opposite end. Sub-

merge the strainer in the

water at least four (4)

times the pipe diameter

below the water level.

Make sure the suction line

connection is tight. (See

Figure 3-1: “Typical Porta-

ble Pump Installation.”)

Keep the strainer OFF the

bottom of the water

source and away from sand, leaves or other foreign matter which could

block or restrict flow.

4.

Remove engine compartment side panels, if so equipped.

5.

Check engine cooling system for sufficient coolant.

6.

Start the engine. See engine manufacturer’s manual for start-up and opera-

tion procedures.

7.

Check that all drain valves / cocks are fully CLOSED.

Figure 3-1: Typical Portable Pump Installation