Medio - grande – Vollrath GRANDE In-Chamber Vacuum Pack Machines User Manual

Page 24

24

VACUUM PACKING MACHINE

CONDITIONNEUSE SOUS VIDE

MAQUINA DE VACÍO

Operating and service manual / Mode d’emploi et d’entretien

Manual de uso y mantenimiento / Ed. 01 - 2011

REV. 00 - Cod.: 1500386

EN

MEDIO - GRANDE

Fig. 1

INSTALLATION

•

E

•

•

=

=

D

C

B

•

A

B

•

A

5.5

DEFINITIONS OF FUNCTIONS

5.5.1

VACUUM FUNCTION (VAC)

The

VAC parameter is set on a timed basis and is expressed in seconds. The VAC time setting must be appropriate for the actual operating requi-

rements. The time must be set initially at an approximate value of 25-30 seconds and modified in the second cycle, if necessary. To obtain absolute

volume, from the moment the vacuum gauge indicates -1.0 bar, the pump must continue to run for another 10 seconds.

5.5.2

SEALING FUNCTION (SEAL)

After vacuum creation the machine proceeds with bag sealing by means of the sealing bar provided with sealing wire. The sealing time varies according

to the bag basic weight, environmental temperature and the quantity of work to be done. In any case, the seal seam on the bag must be uniform, clearly

marked, without melted points. Set a sealing time suitable for the bag, approximately between 2 and 3 seconds. It is possible to anticipate sealing,

while the machine is in suction, by pressing SEAL key.

5.5.3

INTERRUPTING THE WORK CYCLE

Activate the

STOP, button; the work cycle can be interrupted at any moment; interruption is immediate with air re-entering the chamber. The work cycle

can also be interrupted by means of the

ON/OFF main switch: when the appliance is switched off, the cycle is interrupted but air does not return to

the suction cup: the lid therefore remains closed.

When the appliance is switched on again, the cycle is reset, air returns to the chamber and the lid opens.

6.

USING THE MACHINE

6.1

PREPARATION

WARNING! The product to be packed must be dry and cold to obtain maximum vacuum. The pump performance is reduced if

there is moisture in the product or the vacuum chamber. Therefore, clean the vacuum chamber and insertion plates carefully. Soft

products may be damaged by the compression in the bag when the cycle is complete. Use bags having thickness and size suitable

for the product hardness and dimensions.

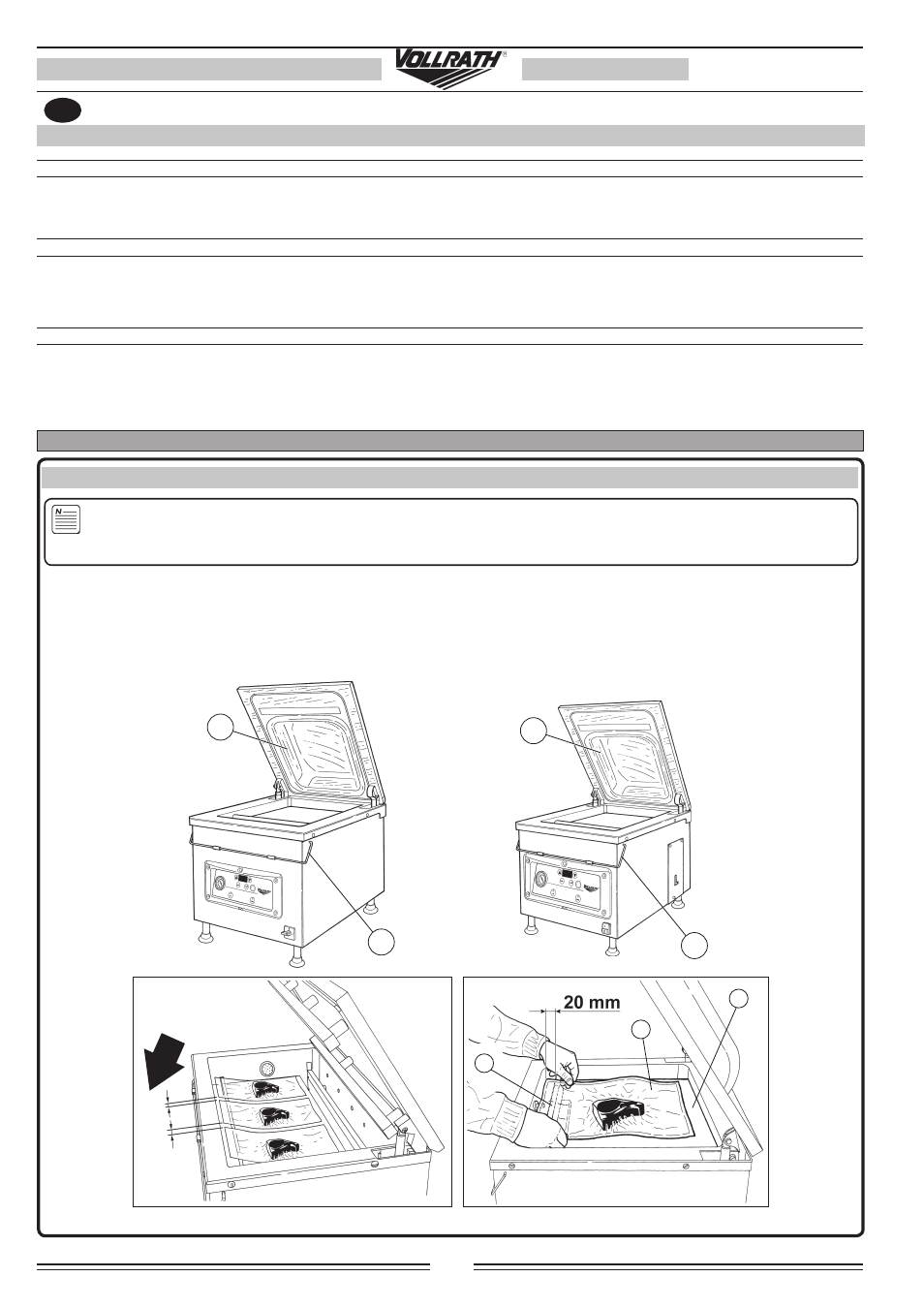

1) Lower lid holder (A): the vacuum chamber plexiglas cover (B) opens. Position the maximum number of insertion plates (C) the chamber can hold,

depending on the dimensions of the product to be packed.The longest insertion plate (in models with insertion plates of different lengths) must always

be at the top as it will otherwise hinder vertical movement of the sealing bar.

2) Choose a bag suitable for the product to be packed (the product must take up 2/3 of the bag volume). Insert inside the vacuum chamber the bag

(D),containing the product to be packed and center it on the sealing bar (E), so that the open edge projects by about 20mm beyond the bar. For

models with bar length sufficient to pack a number of bags simultaneously and for multi-bar models, distribute the bags at regular distances (=)

(Fig.

1).