Medio - grande, Fig. 1 – Vollrath GRANDE In-Chamber Vacuum Pack Machines User Manual

Page 20

20

VACUUM PACKING MACHINE

CONDITIONNEUSE SOUS VIDE

MAQUINA DE VACÍO

Operating and service manual / Mode d’emploi et d’entretien

Manual de uso y mantenimiento / Ed. 01 - 2011

REV. 00 - Cod.: 1500386

EN

MEDIO - GRANDE

5.3

GENERAL REGULATIONS FOR USE

ELECTRIC HAZARD! First check the voltage indicated on the nameplate to make sure it corresponds to that of your mains supply.

ELECTRICAL SAFETY OF THIS MACHINE IS ONLY ENSURED BY CONNECTING IT CORRECTLY TO AN EFFECTIVE EARTHING SY-

STEM, AS ENVISAGED BY SAFETY STANDARDS. THE MANUFACTURER DECLINES ALL RESPONSIBILITY FOR DAMAGE CAUSED

BY THE ABSENCE OF EARTHING OF THE ELECTRICAL SYSTEM.

ELECTRIC HAZARD! Insert and disconnect the plug in the power socket always with the

machine switched off; pull out the plug, not the cable.

Only qualified personnel are allowed to access powered parts.

CAUTION: To provide continued protection against risk of electric shock, connect

to properly grounded outlets only.

WARNING! Position the machine on a solid, safe level horizontal work table.

WARNING! The appliance must be positioned in such a manner as to allow access from all sides.

This will also ensure necessary ventilation of the machine.

In any case, there must be a clearance of at least 10 cm around the machine.

ATTENTION! If the vacuum and sealing time parameters of the work cycle are set at the maximum value, (at approx. 50 seconds of

vacuum and 6 seconds of sealing), there must be an interval of at least 30 seconds between cycles.

WARNING! To avoid increase in oil density which could affect regular working of the pump, make sure

that the environmental temperature never falls below 10°C.

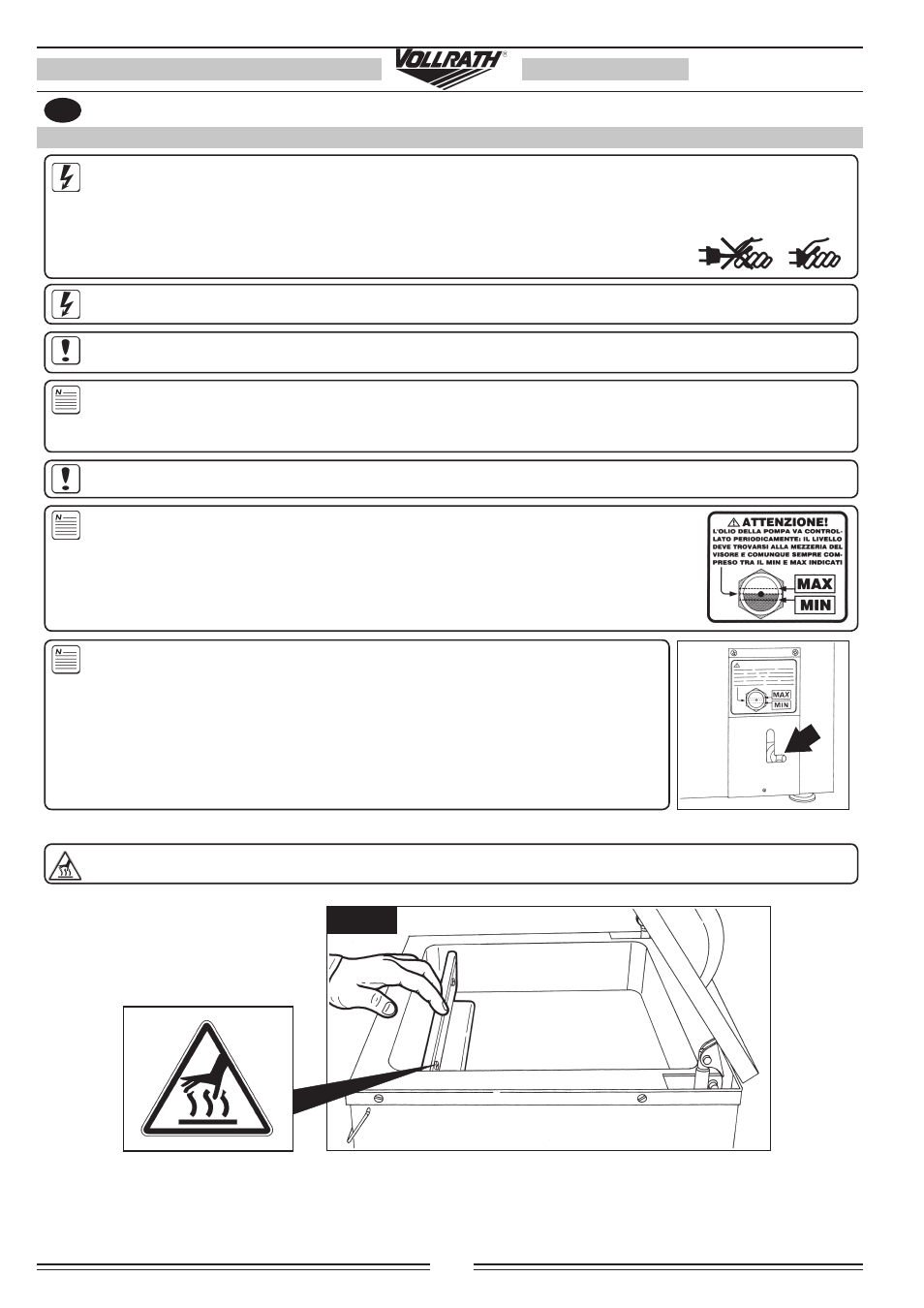

WARNING! The pump oil must be checked every time the machine is used through the level glass provided

on the side of the machine’s rear panel. The oil level must be between the MINIMUM and MAXIMUM level.

The oil must be golden coloured and clear.

WARNING! THE PUMP OIL MUST BE CHANGED PERIODICALLY; THE OIL CHANGE FREQUENCY MUST BE

INCREASED PROPORTIONALLY TO THE WORKLOAD TO WHICH THE MACHINE IS SUBJECTED.

THE OIL MUST BE CHANGED EVERY 15,000 OPERATING CYCLES (CORRESPONDING TO APPROX.

100 HOURS OF OPERATION).

The oil and filter change frequency increases if liquids or wet products are handled; in such cases, the oil

must be changed if the machine has remained unused for a month or a longer period. A whitish, cloudy

or dark and transparent oil means suction of liquids and moisture, or that the oil is old, respectively.

ATTENTION! Do not touch the sealing bars after sealing a bag as they may be very hot (Fig. 1).

NO

OK

INSTALLATION

NO!

Fig. 1