Medio - grande – Vollrath GRANDE In-Chamber Vacuum Pack Machines User Manual

Page 22

22

VACUUM PACKING MACHINE

CONDITIONNEUSE SOUS VIDE

MAQUINA DE VACÍO

Operating and service manual / Mode d’emploi et d’entretien

Manual de uso y mantenimiento / Ed. 01 - 2011

REV. 00 - Cod.: 1500386

EN

MEDIO - GRANDE

WARNING! Do not remove the Teflon cover on the sealing bars; do not use knives or other sharp

tools to remove residua from the sealing bar: always wait for the bars to cool down before using

blunt tools.

WARNING! Clean the machine thoroughly after use; clean the plexiglas cover using only a cloth dipped in

water, avoid cleaning liquids and solvents. Use the special products available on the market for cleaning

the stainless steel parts. Do not use water or steam jets as this can damage the machine’s electrical

equipment.

In order to clean the suction nozzles, carry out the DEHUMIDIFICATION CYCLE program (fig. 1).

For all problems (defective working or technical assistance) please contact our Customer Service.

5.4

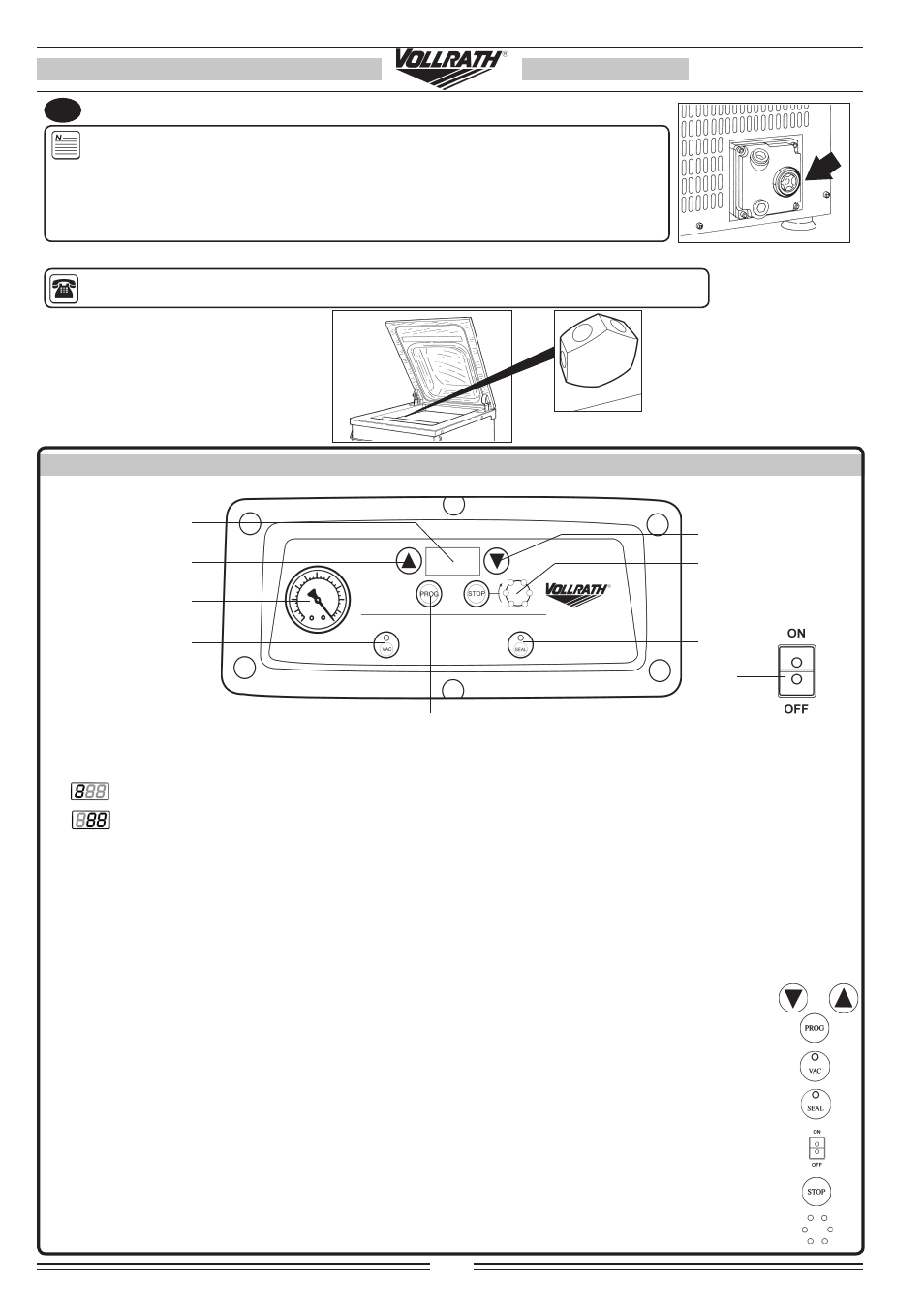

CONTROL PANEL

1

VACUUM GAUGE ( 0÷1 bar ): MEASURES VACUUM IN THE VACUUM CHAMBER.

2

THREE-DIGIT DISPLAY

1° DIGIT TO THE LH: INDICATES THE PROGRAM NUMBER ENTERED

2° AND 3° DIGIT: INDICATE THE VALUE RELATIVE TO THE FUNCTION ACTIVATED

•

DISPLAY FUNCTION ENTERED:

VAC = VACUUM

SAL = SEALING

• ALSO INDICATES THE NUMBER OF CYCLES CARRIED OUT AND THE OIL CHANGE ALARM.

Once the maximum number of 20000

executed work cycles has been reached, as soon as the appliance is switched on and after every work cycle, the

words

ALL” and “OIL” will appear alternately on the display. This is to indicate the need to change the pump oil. Proceed in replacement as indicated

paragraph “CHANGING THE PUMP OIL”. The number which appears on the display must be multiplied by 100 (e.g.: the figure

048 indicates that

48x100= 4800 work cycles have been executed).

3

CURSOR PROGRAMS SELECTION:

INCREASES/DECREASES THE VALUES OF THE INDIVIDUAL FUNCTIONS IN THE PROGRAM.

4

PROG PROGRAMMING KEY: MAKES IT POSSIBLE TO ENTER FUNCTIONS PROGRAMMING.

5

VAC VACUUM PROGRAMMING KEY:

MAKES IT POSSIBLE TO ENTER THE VACUUM FUNCTION PROGRAMMING OR TO DISPLAY THE VALUE.

6

SEAL SEALING TIME PROGRAMMING KEY:

MAKES IT POSSIBLE TO ENTER THE SEALING FUNCTION PROGRAMMING OR DISPLAY THE VALUE;

MAKES IT POSSIBLE TO STOP THE ACTIVE OPERATING PHASE AND PROCEED WITH THE NEXT ONE.

7

ON/OFF MAIN SWITCH WITH RED INDICATOR LED:

MACHINE ON/OFF AND INTERRUPT CYCLE.

8

STOP STOP BUTTON: STOPS THE WORK CYCLE.

9

PUMP RUNNING INDICATOR LED.

1

5

4

8

6

9

3

2

3

7

INSTALLATION

Fig. 1