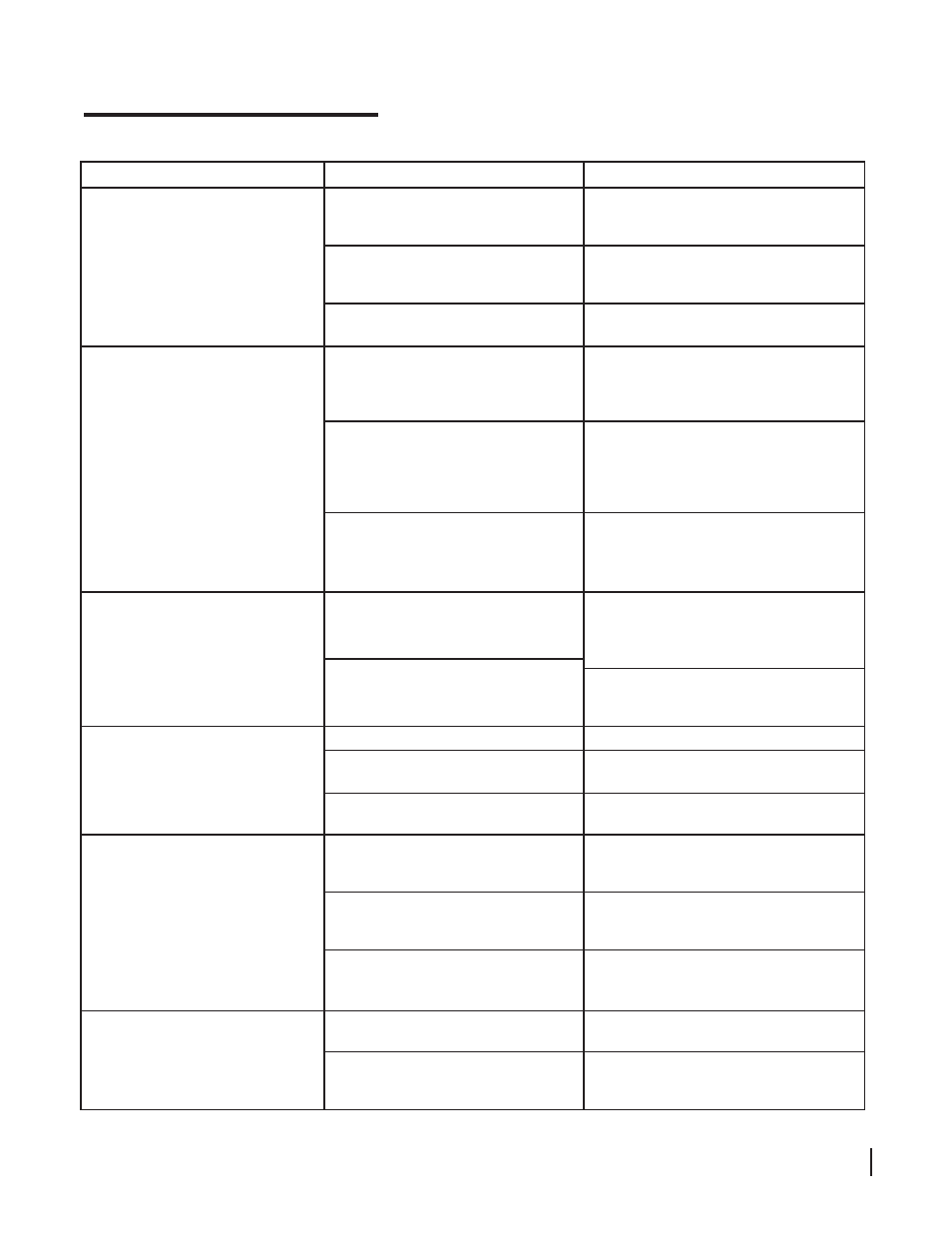

Troubleshooting, Problem possible cause(s) solution – SawStop 3.0HP User Manual

Page 91

SawStop 10” Professional Cabinet Saw 89

Troubleshooting

Problem

Possible Cause(s)

Solution

Cannot turn the saw on in Bypass

Mode.

1. The sequence for starting the

saw in Bypass mode was not

completed.

1. Follow the steps for starting the saw in

Bypass mode exactly.

2. The safety system has detected a

system error and is displaying an

error code on the LEDs.

2. Consult the list of System Status

Codes to determine the cause of the

error and the corrective action.

3. The Bypass key is not fully seated.

3. Insert the Bypass Key fully and ensure

it turns a full 90

°.

The brake activated even though

there was no accidental contact.

1. Some electrically conductive

material contacted the blade, arbor

or arbor pulley.

1. Make sure no metal or other

conductive material is touching the

blade, arbor or pulley. Use Bypass

Mode to cut conductive materials.

2. The spreader or riving knife came

into contact with the blade.

2. Ensure that the spreader or riving knife

is accurately aligned and securely

clamped in place. There should be a

gap of at least 4-7 mm between the

blade and the spreader or riving knife.

3. The blade made contact with the

brake pawl.

3. Make sure there is a gap of

1

⁄

16

inch

to

1

⁄

8

inch between the teeth of the

blade and closest point on the brake

cartridge (see pages

30 and 31

).

The blade hits the brake pawl during

installation.

1. The brake position is adjusted too

close to the blade.

1. Turn the brake positioning bolt counter-

clockwise until the closest point

between the brake pawl and the blade

is about

1

⁄

16

inch to

1

⁄

8

inch.

2. The blade is the wrong size.

2. Use only a 10 inch blade with a

standard brake cartridge, or an 8 inch

dado set with a dado cartridge.

Cannot remove the brake cartridge.

1. The cartridge key is still installed.

1. Remove the cartridge key.

2. The cartridge is bound up on the

pivot pin and the positioning pin.

2. Pry the cartridge off the pins with a

blade wrench as described on page

60.

3. The quick-release clamp handle is

in the way.

3. Swing the clamp handle fully upward to

clear the cartridge.

Cannot install the brake cartridge.

1. The holes in the cartridge shell are

not aligned with the pivot pin and

positioning pin.

1. Make sure the mounting holes in the

cartridge are aligned with the pivot and

positioning pins.

2. There is debris on the pivot or

positioning pins, or in the cartridge

mounting holes.

2. Make sure the pins and mounting holes

are clean and free of obstructions.

3. The blade is interfering with the

brake pawl.

3. Adjust the brake positioning bolt to

move the cartridge mounting bracket

away from the blade.

Cannot remove the cartridge key.

1. The cartridge key is not turned to

the UNLOCKED position.

1. Turn the key clockwise until it stops.

2. The shaft of the cartridge key is

binding in the cartridge or on the

cartridge mounting bracket.

2. Try turning and removing the key while

pressing upward or downward on the

key or cartridge.