Making adjustments to your saw – SawStop 3.0HP User Manual

Page 66

64 SawStop 10” Professional Cabinet Saw

Fig. 99

Making Adjustments to Your Saw

Next, set the tilt angle to 0º. When setting the tilt angle and blade elevation, be sure to back the handwheels off

slightly after reaching the limit stops. As with all table saws, pulling the handwheels tight against the limit stops

can cause a slight twisting of the trunnion assembly and lead to inaccurate alignment measurements.

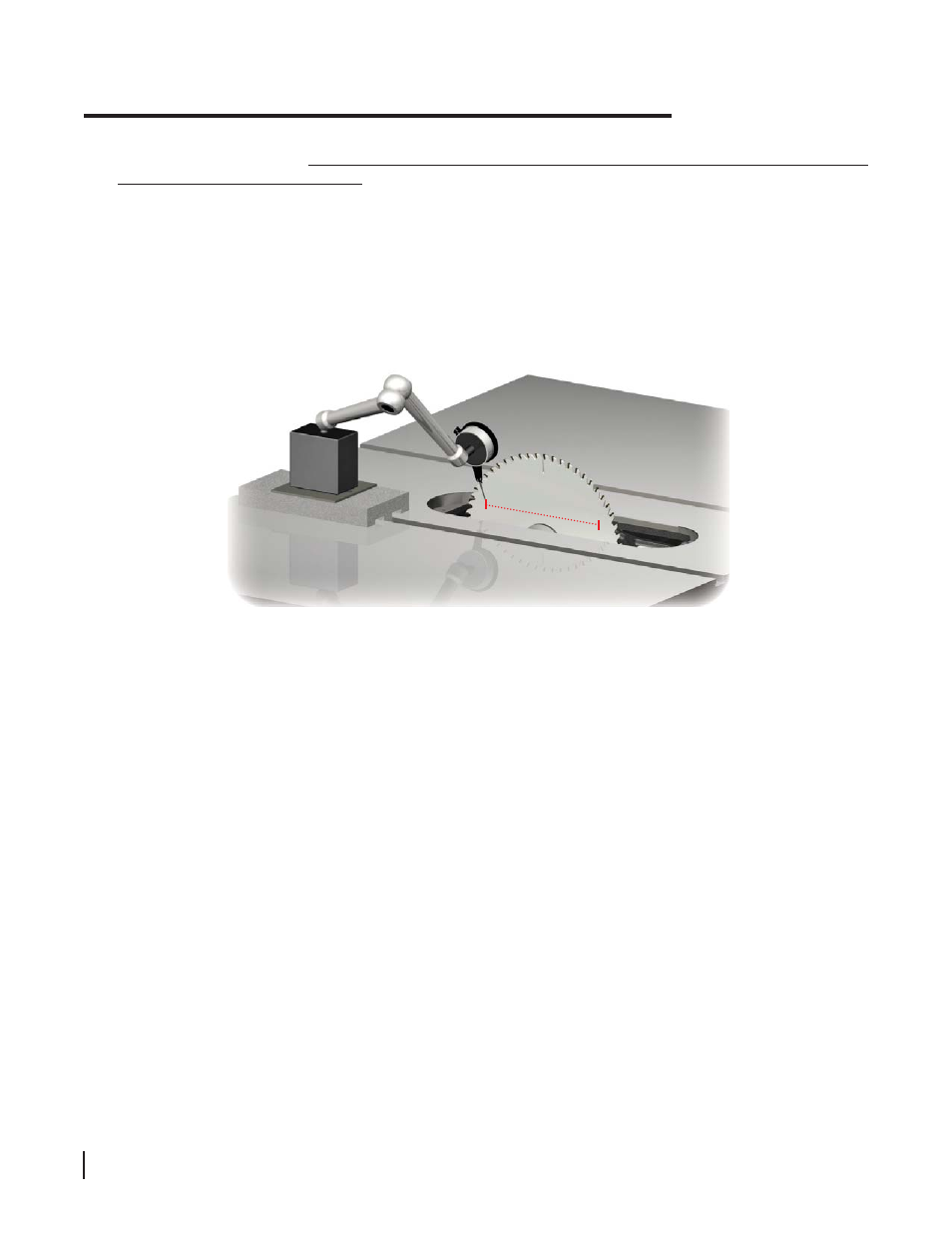

Raise the blade elevation to about 3 inches above the table. Position the dial test indicator so that the

measurement arm rests against the right side of the blade and about

1

⁄

4

inch above the center of the arbor

fl ange. Slide the mount forward until the measurement arm is about

1

⁄

2

inch inside the front edge of the blade

(see Fig. 99).

Set the dial indicator to zero. Slide the dial test indicator mount smoothly toward the back of the saw until the

measurement arm is about

1

⁄

2

inch inside the rear edge of the blade. Note the reading of the dial indicator as

the mount moves across the blade.

If the dial indicator moves positive and then negative (or vice versa) a substantial amount, or if there is a

sudden change in the reading rather than a gradual change, this indicates a non-fl at area of the blade. If this

happens, try rotating the blade

1

⁄

4

turn and retesting. Repeat this process until you get a reading that is not

signifi cantly affected by blade fl atness. If you cannot get a good reading, try a different blade.

If there is a gradual and continuous change in the dial reading of over 0.002 inch in either the positive or

negative direction, rotate the blade

1

⁄

2

turn. Slide the dial indicator mount back toward the front of the blade

and reset the indicator to zero. Now slide the mount toward the back of the saw again while noting the dial

reading. If there is similar change but in the opposite direction, this indicates that the left and right surfaces of

the blade are not parallel. Rotate the blade

1

⁄

4

turn and repeat the process from the beginning. If you cannot

get consistent readings, try a different blade.

If the dial indicator reads a relatively consistent difference between the front and rear of the blade, take the

average of the readings. A measurement of 0.002 inch or less indicates that the table is aligned within the

margin of error for this measurement and no further alignment is necessary. For measurements larger than

0.002 inch, you can adjust the position of the table to improve the parallelism between the blade and the miter

slot.