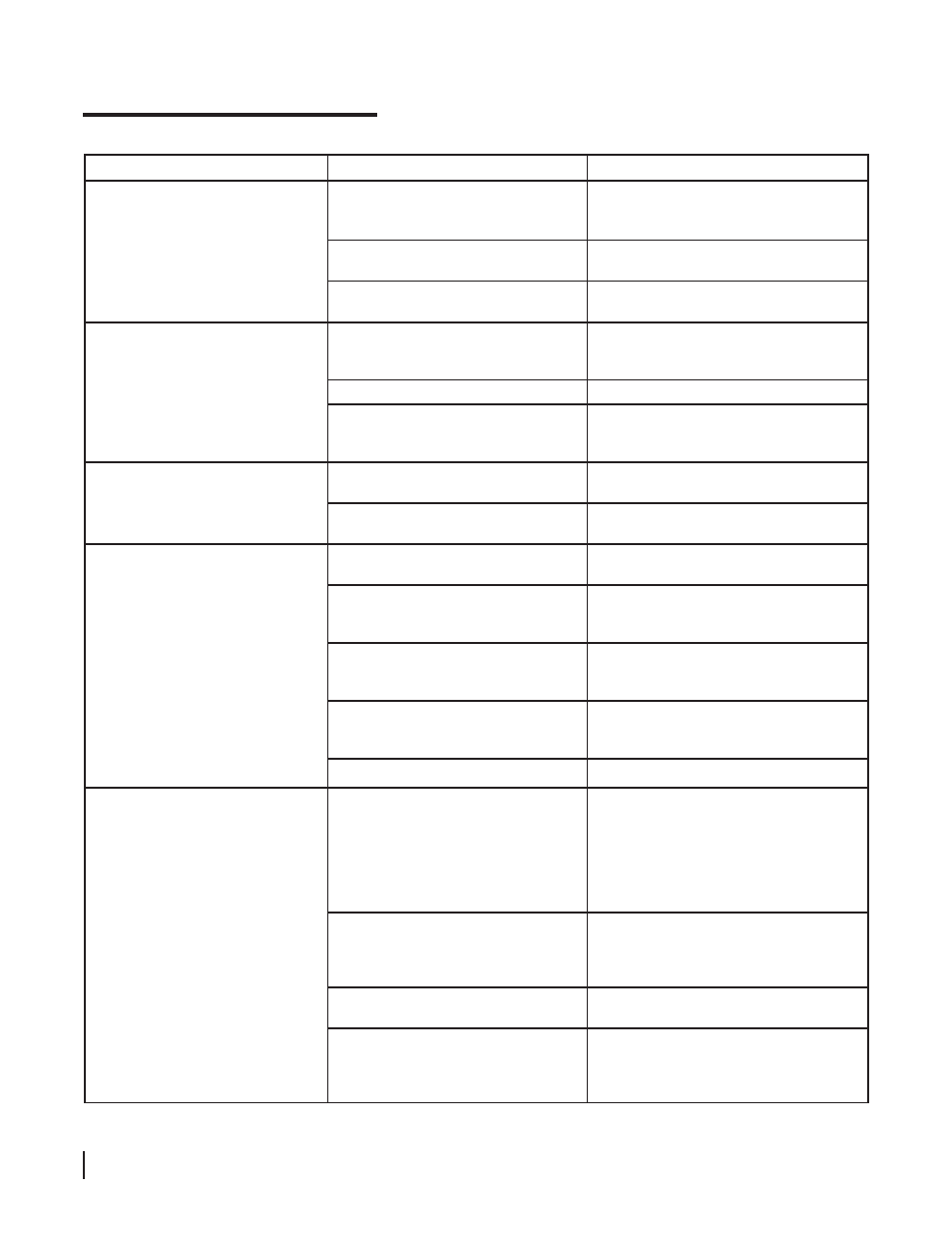

Troubleshooting, Problem possible cause(s) solution – SawStop 3.0HP User Manual

Page 90

88 SawStop 10” Professional Cabinet Saw

Troubleshooting

Problem

Possible Cause(s)

Solution

The motor will not start and both

LEDs on the switch box are off.

1. There is no power to the saw.

1. Ensure that the electrical supply to the

saw is on and that the correct voltage

is being supplied.

2. There is no brake cartridge installed

in the saw.

2. Install the brake cartridge.

3. The brake cartridge is defective.

3. Replace the brake cartridge with a new

cartridge.

The motor will not start and at least

one LED on the switch box is on.

1. The safety system has detected a

system error and is displaying an

error code on the LEDs.

1. Consult the list of System Status

Codes to determine the cause of the

error and the corrective action.

2. The cartridge is defective.

2. Try a different brake cartridge.

3. The thermal overload switch cut

power to the motor to prevent

overheating.

3. Press the thermal overload reset

button on the contactor box behind the

left side of the switch box.

The motor starts slowly and/or fails

to reach nominal speed.

1. The electrical supply voltage is too

low.

1. Ensure that the correct voltage is being

supplied to the saw.

2.

The belts are worn or slipping.

2.

Adjust the tension in the belts or

replace if worn.

The motor stopped unexpectedly

during use but the brake did not

activate.

1. The Start/Stop paddle was bumped.

1. Ensure the Start/Stop paddle is in the

OFF position and restart the saw.

2. The material being cut is

overloading the safety detection

system (e.g., green or wet wood).

2. Use different wood or cut in Bypass

Mode.

3. The safety system has detected a

system error and is displaying an

error code on the LEDs.

3. Consult the list of System Status

Codes to determine the cause of the

error and the corrective action.

4. Electrical power to the system was

lost at least temporarily.

4. Ensure that the electrical supply to the

saw is on and that the correct voltage

is being supplied.

5. The cartridge is defective.

5. Try a different brake cartridge.

The blade slows down when cutting,

but does not stop.

1. One of the belts is worn, damaged

or not properly tensioned.

1. Check the tension of the motor belt

and arbor belt. If the motor belt is too

loose, adjust the position of the motor

to provide the correct tension on the

motor belt. If the arbor belt is too loose,

replace it with a new belt. Replace any

worn or damaged belts.

2. The blade is binding on the wood.

2. Ensure the spreader or riving knife is

aligned with the blade. If using the rip

fence, ensure it is aligned parallel to

the blade

3. The blade is installed backwards.

3. Remove the blade and reinstall in the

correct orientation.

4. The voltage supplied to the motor is

incorrect.

4.

Ensure the motor is wired to match

the power that is being supplied. If

using an extension cord, ensure the

extension cord is the correct gauge.