Making adjustments to your saw – SawStop 3.0HP User Manual

Page 70

68 SawStop 10” Professional Cabinet Saw

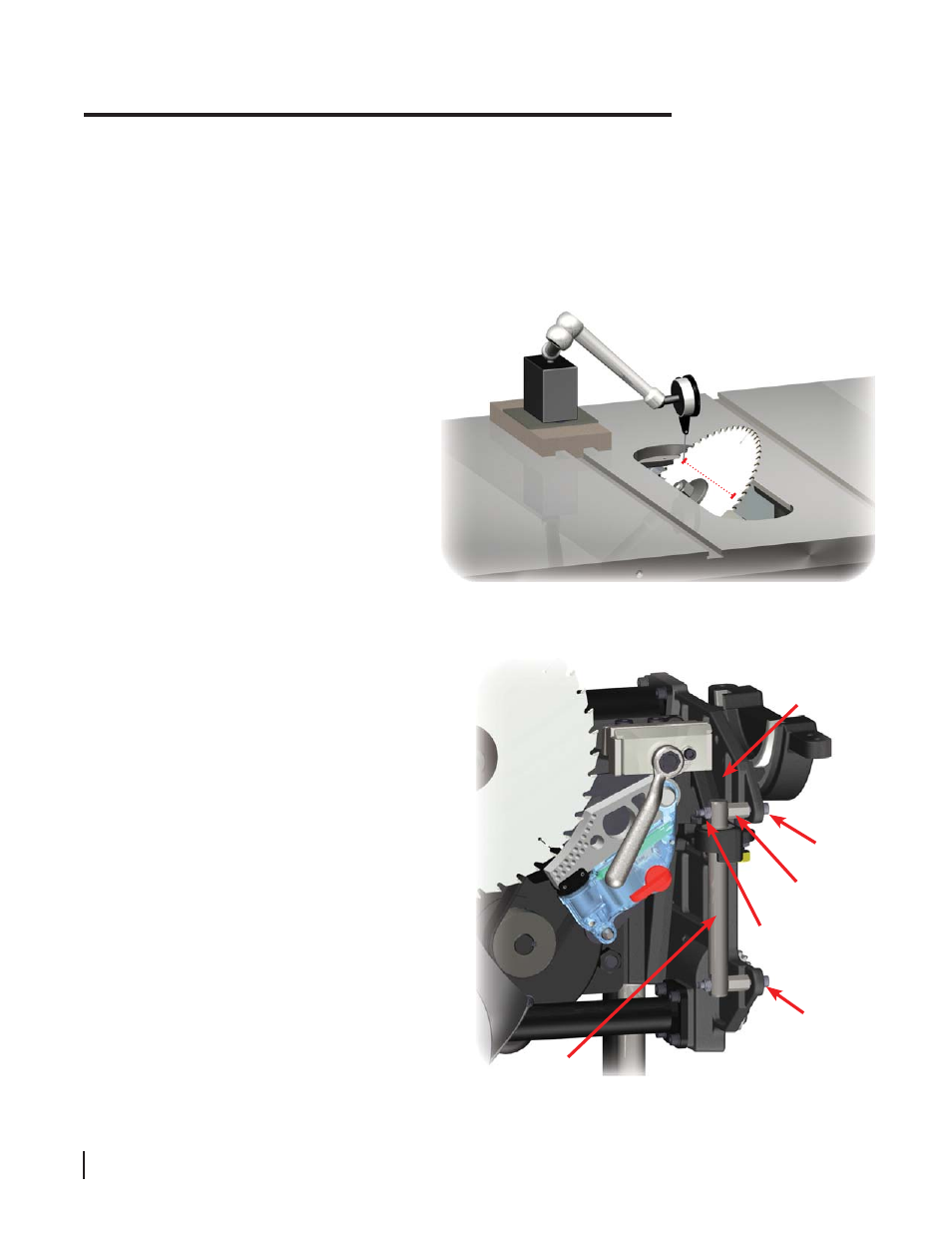

standoff

nut

secondary

elevation

shaft

top

bolt

bottom

bolt

rear

trunnion

Fig. 106

Next, move the dial indicator measurement arm so that it is not touching the blade and tilt the blade to

approximately 45º. Make sure not to tighten the tilt handwheel against the 45º limit stop. Now reposition the

dial indicator measurement arm against the right side of the blade and about

1

⁄

4

inch directly above the arbor

fl ange. Slide the dial indicator mount toward the front of the saw until the measurement arm is about

1

⁄

2

inch

inside the front edge of the blade (see Fig. 106). Set the dial indicator readout to zero.

Slide the dial test indicator mount smoothly

toward the back of the saw until the

measurement arm is about

1

⁄

2

inch inside

the rear edge of the blade. Note the reading

of the dial indicator as the mount moves

across the blade. Write down the fi nal

number, including whether it is positive or

negative. This number is proportional to the

misalignment between the blade and the tilt

axis.

If the measurement is 0.002 inch or less,

then the blade is parallel to the tilt axis

within the margin of error for this procedure

and no further alignment is necessary. For

measurements larger than 0.002 inch, you

can adjust the angle of the blade to improve

the parallelism between the blade and the

tilt axis. The adjustment must be made at a

0º tilt angle.

To do this, move the dial test indicator away

from the blade, set the tilt angle back to 0º

and reposition the dial test indicator at the

front of the blade. When you slide the dial

indicator mount across the blade, you should

see little or no change in the indicator readout

since the table was previously aligned. Now,

slide the dial indicator toward the front of the

saw until the measurement arm is about

1

⁄

2

inch inside the rear edge of the blade. Set

the readout to zero.

The angle of the blade relative to the tilt

axis is controlled by two bolts that bolt the

secondary elevation shaft to the rear trunnion

(see in Fig. 107).

Fig. 107

Making Adjustments to Your Saw