SawStop T-Glide User Manual

Sawstop, Contractor saw, Flip to other side

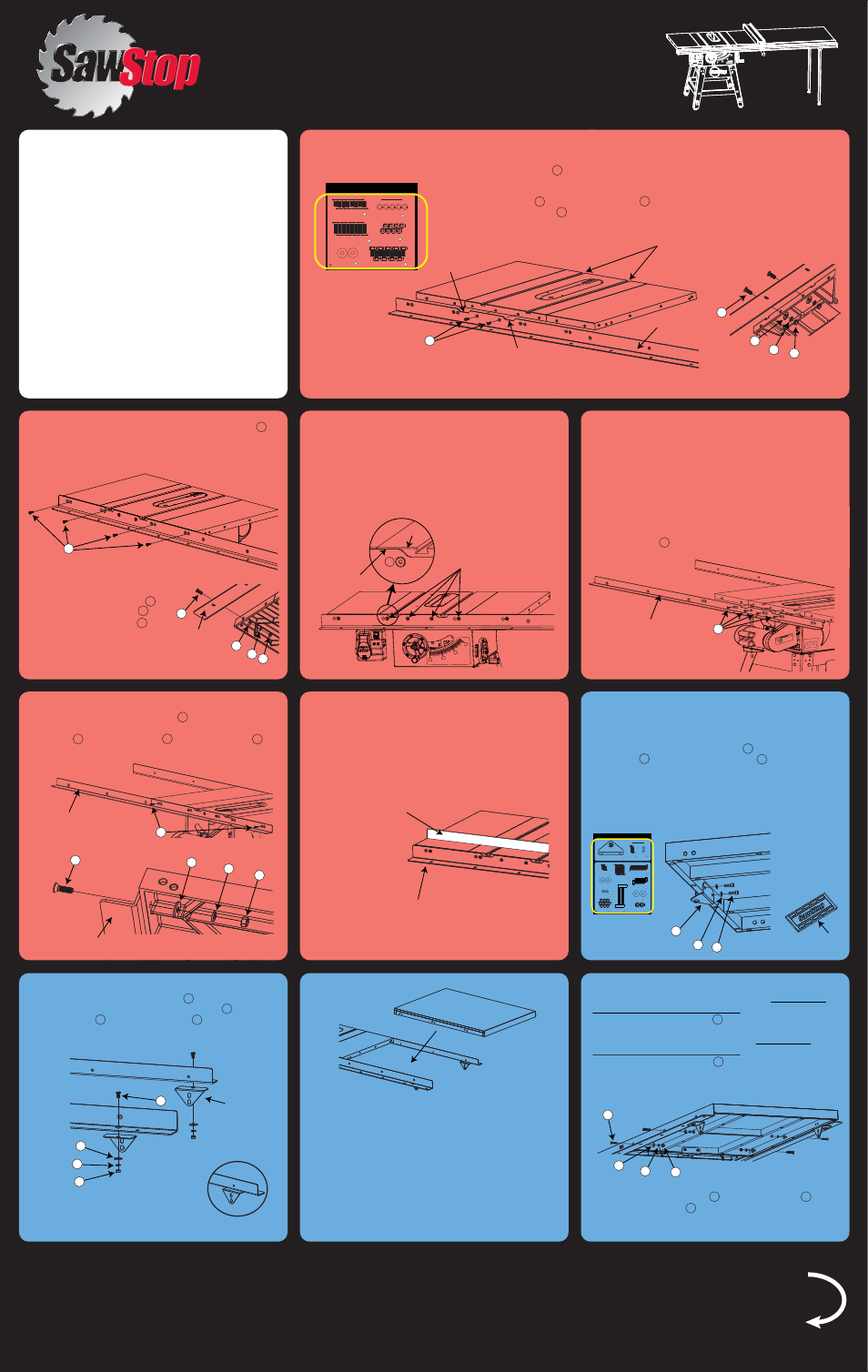

Fig. 2a

• Take four more M8 x 25 countersunk socket head bolts

and insert them through the four open holes in the front rail

and table (see Fig. 2a).

2

• The holes in the front edge of the table and extension wings are

slightly larger than the bolts they receive to allow you to level the

front rail and extension wings to the table top. Align the top of

the front rail with the lower edge of the bevel on the front edge of

the table top. Use a 5 mm hex key and a 13 mm wrench to

fully tighten the nuts on the back of the four bolts that extend

through the table top. Do not tighten the nuts on the bolts that

extend through the extension wings.

SawStop Service

Department

503-582-9934

www.sawstop.com

Flip to

Other Side

© SawStop, LLC

5

7

10

• Once the rails are in place you can mount the extension table

to the rails. The hardware needed to mount the extension table

is in the T-Glide Table Hardware Pack.The first step is to install

the adjustment bracket included in the T-Glide Table Hardware

Pack. Remove the adjustment bracket , two M6 x 18 socket

cap screws , and two M6 lock washers from the T-Glide

Table Hardware Pack, and place a lock washer on each screw.

One end of the extension table includes two holes and the

adjustment bracket has two corresponding holes. Position the

adjustment bracket against the inside edge of the extension

table, align the holes, and thread the screws into the holes.

Tighten the screws with a 5 mm hex key.

14

15

13

4

2

Fig. 2b

Place an M8 washer ,

an M8 lock washer ,

and an M8 hex nut on

the threaded end of each of

the M8 x 25 bolts (see Fig. 2b).

Hand tighten the nuts;

do not fully tighten them.

3

5

4

• Use a straight-edge to level the front edge of the left extension

wing to the cast iron table top. You may have to pull up or push

down on the outer edge of the extension wing to level it. Once

the front edge of the left extension wing is level, use a 5 mm hex

key and a 13 mm wrench to fully tighten the nut on the bolt that

mounts the left extension wing to the front rail. Repeat this

process to level the front edge of the right extension wing and

the rear edges of the left and right extension wings.

1

Before assembling your T-Glide fence system,

make sure that you have all the necessary

components identified on page 1 in the Owner’s

Manual, including the two hardware packs. Call the

SawStop Service Department at 503-582-9934 if

any components are missing. You will need the

following tools to complete the fence installation:

1. a 13 mm wrench

2. two 17 mm wrenches (or adjustable wrenches)

3. a 5 mm hex key

4. a level or straight-edge

Note: The following drawings show how to assemble

both the 52” and 36” fence systems. Although the

components shown are for the 52” fence system,

the components for the 36” system are similar.

• The extension table mounts to the rails with bolts that pass

through holes in the rails and extension table. If you have an

extension table for a 36” fence system, take two M8 x 35

countersunk socket head bolts and insert one through the

hole in the front rail closest to the saw and the other through

the hole in the rear rail closest to the saw. If you have an

extension table for a 52” fence system, take four M8 x 35

countersunk socket head bolts and insert one bolt into each

of the two holes in the front rail closest to the saw, and one bolt

into each of the two holes in the rear rail closest to the saw.

20

20

Place an M8 washer , an M8 lock washer , and

an M8 hex nut on the threaded end of each bolt and

hand tighten the nuts. Do not insert bolts through the

outermost holes in the front and rear rails at this time.

17

18

19

• Place the extension table between the rails and slide it towards

the extension wing. Be careful when positioning the extension

table because it is not yet secured to the rails and could fall. You

will need to tilt the extension table slightly for the adjustment

bracket to fit under the extension wing. The adjustment bracket

includes a screw that extends upward and the underside of the

extension wing includes a hole to receive the screw. Fit the screw

into the hole, and then turn the screw until the extension table is

roughly flush with the extension wing. The opposite end of the

extension table will rest upon the leg support brackets

but will not be level because the leg support brackets

are at different elevations and are not intended to

support the extension table once it is fully installed.

9

• Finish mounting the rear rail to your saw by inserting an

M8 x 25 countersunk socket head bolt through the open hole

at the end of each extension wing (see Fig. 5a) and placing an

M8 washer , an M8 lock washer , and an M8 hex nut on

the threaded end of each bolt (see Fig. 5b). Hand tighten the nuts;

do not fully tighten them.

3

5

4

2

Fig. 5a

rear rail

6

Made in Ta

iwan

SawStop, L

LC

www.saw

stop.com

TCP

10¨ Contr

actor Saw

SawStop

®

Model No. C

NS 175

Serial No. C

074012345

Electrical / Electricid

ad / Électric

ité

115/230 Vol

ts, 60 Hz

15/7.5 Amp

s

1 Phase

1.75 HP

3500 RPM

®

c

US

175370

Movi

ng b

elts a

nd p

arts

can

pinch

, cut or

crush.

Do not o

per

ate wi

th

belt gua

rd o

pen.

• Begin mounting the rear rail (the shorter of the two rails) to the

rear edge of your saw by centering the notches in the rail with

the two miter slots in the table and aligning the left-most hole

between the notches with the corresponding hole in the rear

edge of the table. There are three holes in the rail between the

notches, one solitary hole and two holes paired together, and the

left-most hole is the solitary hole. Not all the holes are used to

mount the rail to your saw; different holes are used for different

saws. Aligning the left-most hole aligns all the other holes used

in mounting the rail to your saw. When the holes are aligned,

mount the rail to the saw by threading an M8 x 16 countersunk

socket head bolt into each of the four open holes in the rear

edge of the table and tighten the bolts using a 5 mm hex key.

1

• Begin mounting the front rail (the longer of the two rails) to the front edge of your saw by centering the notches in the rail with the two

miter slots in the table, aligning the two holes in the rail between the notches with the two corresponding holes in the front edge of the

table, and inserting an M8 x 25 countersunk socket head bolt into each hole (see Fig. 1a). Aligning the two holes between the

notches aligns all the other holes used in mounting the rail to your saw. Not all the holes are used to

mount the rail to your saw; different holes are used for different saws. Insert the bolts one at a time,

placing an M8 washer and an M8 lock washer on the threaded end of each bolt and then

threading on an M8 hex nut (see Fig. 1b). Hand tighten the nuts; do not fully tighten them.

2

5

3

4

Fig. 1b

Fig. 1a

front rail

miter slots

notch

notch

level the extension wing

and tighten the nut on the

bolt that goes through

the extension wing

straight-edge

Installing Your T-Glide Fence System on Your

TM

rear rail

8

16

17

19

18

Fig. 8a

• Locate the two leg support brackets. Remove the two

M8 x 20 countersunk socket head bolts from the T-Glide

Table Hardware Pack along with two M8 washers , two

M8 lock washers and two M8 hex nuts . Mount one leg

support bracket to the underside of each of the rails as shown

in Fig. 8a. Hand tighten the nuts; do not fully tighten them.

16

17

18

19

Fig. 8b

Once mounted, the brackets

should create a shelf as shown

in Fig. 8b.

3

®

Contractor Saw

SawStop

front rail

Fig. 5b

0

15

30

45

SawStop

10” Contractor Saw

SA

WSTOP

T-Glide Rails Hardware Pack

2

Countersunk Socket Head Bolts,

M8 x 25 (8)

Washers,

M8 (8)

3

Lock Washers,

M8 (17)

4

II

Professional Series

Countersunk Socket

Head Bolts, M8 x 16 (8)

1

Hex Head Bolts, M8 x 16 (9) 6

Hex Nuts,

M8 (8)

5

F

Washers,

M10 (4) 24

20

Countersunk Socket

Head Bolts, M8 x 35 (4)

Lock Nuts,

M10 (2)

25

Adjustment Bracket,

with Custom Screw Assembly (1)

13

Lock

Washers,

M6 (2)

15

Socket

Cap Screws,

M6 x 18 (2)

14

T-Glide Table Hardware Pack

Lock Washers,

M8 (8)

18

Washers,

M8 (8) 17

16

Countersunk Socket

Head Bolts, M8 x 16

(2)

Hex Nuts,

M8 (10) 19

Foot,

(2)

21

22

Countersunk Socket

Head Bolts, M8 x 65 (2)

Hex Head Bolts,

M10 x 40 (2)

23

II

Professional Series

F

Fold line

Height = 664 mm

332 mm

14

13

15

leg support

bracket

20

17

18

19

2

2

3

4

5

Ma de in Ta

iwan

SawStop , L

LC

www.saw

stop.com

TCP

10¨ Contra

ctor Saw

SawStop

®

Model No. CNS

175

Serial No. C07

4012345

Electrical /

Electricidad /

Électricité

115/230 V

olts, 60 Hz

15/7.5 Am

ps

1 Phase

1.75 HP

3500 RPM

®

c

US

175370

Movi

ng b

elts

and pa

rts

can pinch

, cut or c

rush

.

Do not o

per

ate w

ith

belt gua

rd o

pen.

rear rail

1

2

3

4

5

2

Use M8 x 25 bolts

2

2

3

4

5

0

15

30

45

SawStop

10” Contractor Saw

level the top of

the front rail with

the lower edge

of the bevel

bevel

tighten

stamped

wing

Note: The adjustment

bracket is for cast iron

wings only. If you have

a Contractor Saw with

stamped wings, you

may skip this step

and go to step 8.