5 bridge resistance measurements – Campbell Scientific CR7 Measurement and Control System User Manual

Page 139

SECTION 13. CR7 MEASUREMENTS

13-15

is 100 oC and the upper limit of the extension

grade wire is 200 oC. With the other types of

thermocouples the reference compensation

range equals or is greater than the extension

wire range. In any case, errors can arise if

temperature gradients exist within the junction

box.

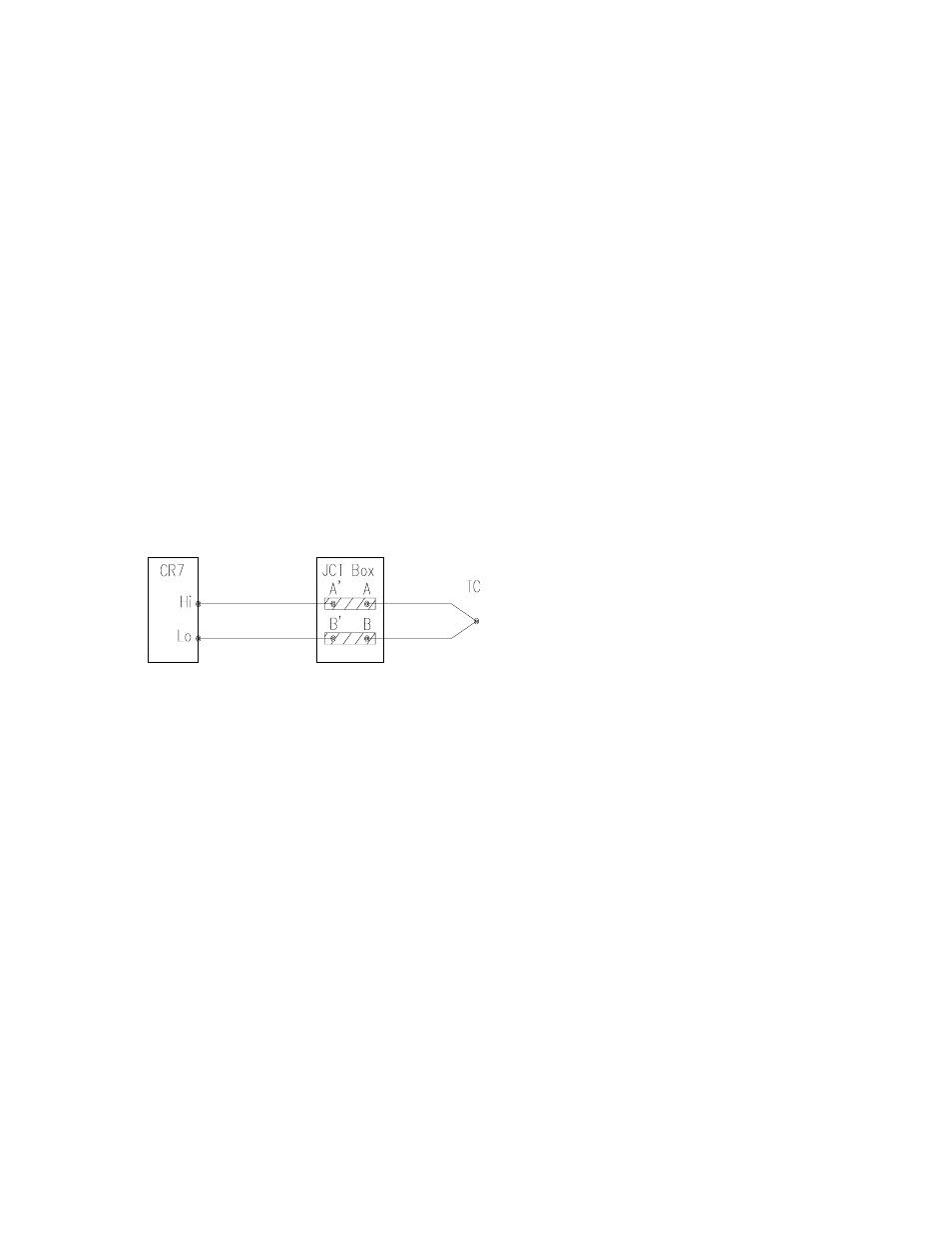

Figure 13.4-1 illustrates a typical junction box.

Terminal strips will be a different metal than the

thermocouple wire. Thus, if a temperature

gradient exists between A and A' or B and B',

the junction box will act as another

thermocouple in series, creating an error in the

voltage measured by the CR7. This

thermoelectric offset voltage is a factor whether

or not the junction box is used for the reference.

it can be minimized by making the thermal

conduction between the two points large and

the distance small. The best solution in the

case where extension grade wire is being

connected to thermocouple wire would be to

use connectors which clamped the two wires in

contact with each other.

Figure 13.4-1. Diagram of Junction Box

An external reference junction box must be

constructed so that the entire terminal area is

very close to the same temperature. This is

necessary so that a valid reference temperature

can be measured and to avoid a thermoelectric

offset voltage which will be induced if the

terminals at which the thermocouple leads are

connected (points A and B in Figure 13.4-2) are

at different temperatures. The box should

contain elements of high thermal conductivity,

which will act to rapidly equilibrate any thermal

gradients to which the box is subjected. It is not

necessary to design a constant temperature

box, it is desirable that the box respond slowly

to external temperature fluctuations.

Radiation shielding must be provided when a

junction box is installed in the field. Care must

also be taken that a thermal gradient is not

induced by conduction through the incoming

wires. The CR7 can be used to measure the

temperature gradients within the junction box.

13.5 BRIDGE RESISTANCE

MEASUREMENTS

There are five bridge measurement instructions

included in the standard CR7 software. Figure

13.5-1 shows the circuits that would typically be

measured with these instructions. In the

diagrams, the resistors labeled Rs would

normally be the sensors and those labeled Rf

would normally be fixed resistors. Circuits other

than those diagrammed could be measured,

provided the excitation and type of

measurements were appropriate.

With the exception of Instruction 4, which

applies an excitation voltage then waits a

specified time before making a single ended

measurement, all of the bridge measurements

make one set of measurements with the

excitation as programmed and another set of

measurements with the excitation polarity

reversed. The error in the two measurements

due to thermal emfs can then be accounted for

in the processing of the measurement

instruction. In Instructions 6-9 the excitation

channel maintains the excitation voltage until

after the analog to digital conversion is

completed. In Instruction 5, the AC half bridge

grounds the excitation channel as soon as the

integration portion of the measurement is

completed. Figure 13.5-2 shows the excitation

and measurement sequence for Instruction 6, a

4 wire full bridge. When more than one

measurement per sensor is necessary

(Instructions 7 and 9), excitation is applied

separately for each measurement (e.g., in

Instruction 9 used for a 4 wire half bridge, the

differential measurement of the voltage drop

across the sensor is made with the excitation at

both polarities and then excitation is again

applied and reversed for the single ended

measurement of the voltage drop across the

fixed resistor.