Campbell Scientific CR7 Measurement and Control System User Manual

Page 128

SECTION 13. CR7 MEASUREMENTS

13-4

Since the peak transient, Veo, causes

significant error only if it is several times larger

than the signal, Vso, error calculations made in

this section approximate Ve'o by Veo, i.e., Veo

≈ Veo-Vso.

If the input settling time constant,

τ , is known, a

quick estimation of the settling error as a

percentage of the maximum error (Vso for

rising, V'eo for decaying) is obtained by knowing

how many time constants (t/

τ) are contained in

the 0.5 ms CR7 input settling interval (t). The

familiar exponential decay relationship is given

in Table 13.3-1 for reference.

TABLE 13.3-1. Exponential Decay, Percent

of Maximum Error vs. Time in Units of

τ

Time

%

Time

%

Constants Max. Error Constants

Max. Error

0

100.0

5

0.7

1

36.8

7

0.1

3

5.0

10

0.004

Before proceeding with examples of the effect

of long lead lengths on the measurement, a

discussion on obtaining the source resistance,

Ro, and lead capacitance, CwL, is necessary.

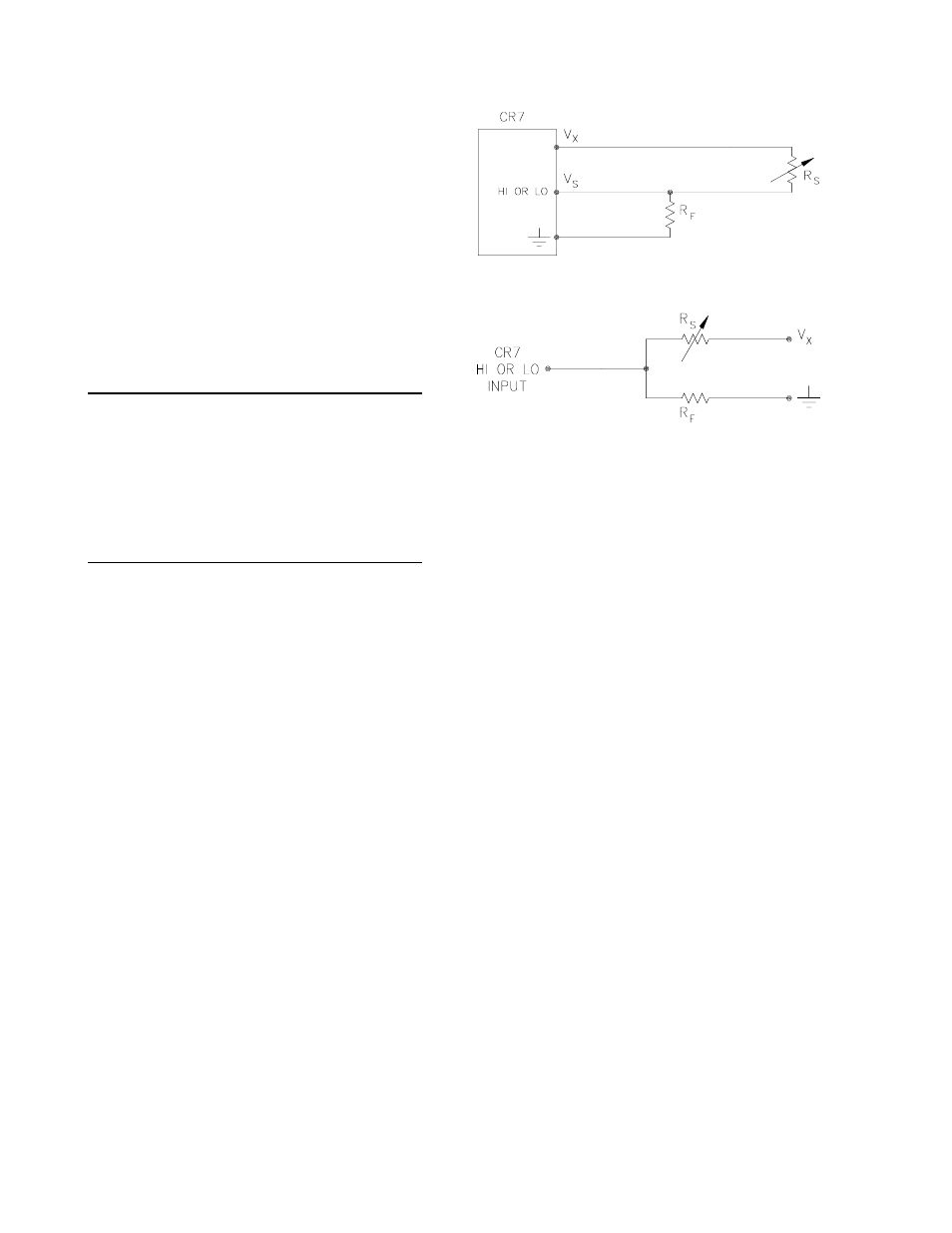

DETERMINING SOURCE RESISTANCE

The source resistance used to estimate the

settling time constant is the resistance the CR7

input "sees" looking out at the sensor. For our

purposes the source resistance can be defined

as the resistance from the CR7 input through all

external paths back to the CR7. Figure 13.3-2

shows a typical resistive sensor, (e.g., a

thermistor) configured as a half-bridge. Figure

13.3-3 shows Figure 13.3-2 redrawn in terms of

the resistive paths determining the source

resistance Ro, is given by the parallel

resistance of Rs and Rf, as shown in Equation

13.3-8.

FIGURE 13.3-2. Typical Resistive Half-Bridge

FIGURE 13.3-3. Source Resistance Model

for Half-Bridge Connected to the CR7

Ro = RsRf/(Rs+Rf)

[13.3-8]

If Rf is much smaller, equal to or much greater

than Rs, the source resistance can be

approximated by Equations 13.3-9 through

13.3-11, respectively.

Ro ≈ Rf, Rf< [13.3-9] Ro = Rf/2, Rf=Rs [13.3-10] Ro ≈ Rs, Rf>>Rs [13.3-11] The source resistance for several Campbell DETERMINING LEAD CAPACITANCE Wire manufacturers typically provide two measurements such as Figure 13.3-2, the pfd/ft. Cw is actually the sum of capacitance between the two conductors and the

Scientific sensors are given in column 3 of

Table 13.3-5.

capacitance specifications 1) the capacitance

between the two leads with the shield floating

and 2) the capacitance between the two leads

with the shield tied to one lead. Since the input

lead and the shield are tied to ground (often

through a bridge resistor, Rf) in single ended

second specification is used in determining lead

capacitance. Figure 13.3-4 is a representation

of this capacitance, Cw, usually specified as

capacitance between the top conductor and the

shield. Capacitance for 3 Belden leadwires

used in Campbell Scientific sensors is shown in

column 6 of Table 13.3-2.