E.2 common replacement parts – Campbell Scientific CPEC200 Closed-Path Eddy-Covariance System User Manual

Page 92

Appendix E. Using Swagelok

®

Fittings

First-time assembly, metal tubing:

Extra care is needed to avoid overtightening brass fittings when used with

metal tubing. These notes apply to reducers and port connectors as well as

metal tubing.

No insert is required with metal tubing.

1. Do not remove the nuts and ferrules from the fitting. Simply insert

the tube into the assembled fitting until it bottoms out.

2. Rotate the nut finger tight.

3. While holding the fitting body steady, tighten the nut until it feels

tight. This will normally be less than one full turn. Tightening a full

one and one-quarter turns will damage the threads on the fitting and

nut.

Reassembly, plastic or metal tubing:

You may disassemble and reassemble Swagelok

®

tube fittings many times, but

the assembly process is slightly different than the first assembly.

1. Insert the tube with pre-swaged ferrules into the fitting until the front

ferrule seats against the fitting body.

2. Rotate the nut finger tight.

3. While holding the fitting body steady, tighten the nut slightly with a

wrench.

E.2 Common Replacement Parts

Tubing

Campbell Scientific can provide several types and sizes of plastic tubing as

shown in TABLE E-1. A tubing cutter, pn 7680, can be used to cut these

tubes.

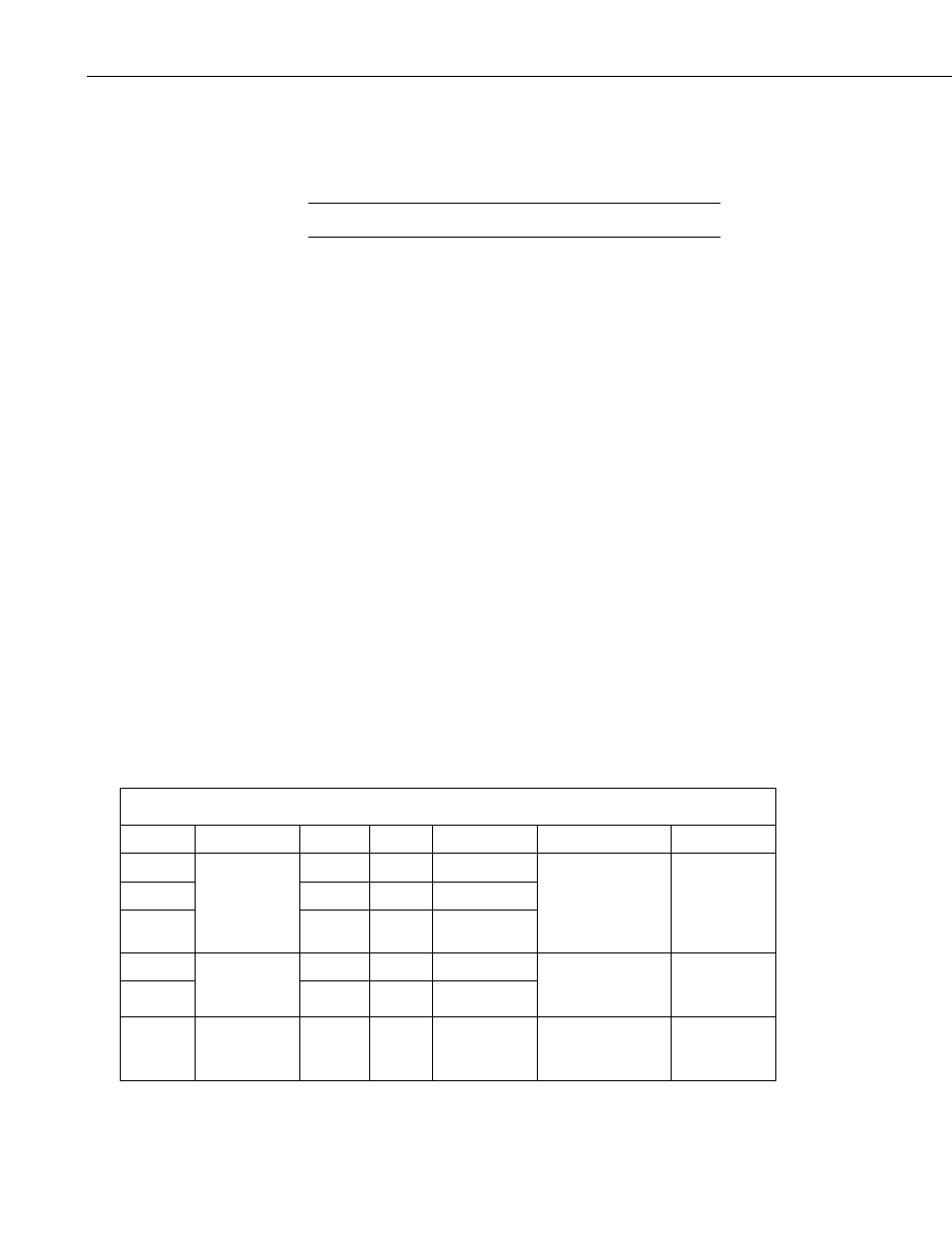

TABLE E-1. Available plastic tubing sizes, construction, and usage guidelines

CSI pn Tubing Type OD (in) ID (in)

Length (ft)

Construction

Notes

15702

Synflex 1300

1/4

0.17

500

Black HDPE

jacket, overlapped

aluminum tape,

ethylene

copolymer liner

Aluminum

layer limits

diffusion; best

for sample

tubes

15703

3/8

1/4

250

19164

1/2

3/8

250

26506

LLDPE

3/8

1/4

500

Black linear low-

density

polyethylene

More flexible

than HDPE

25539

1/2

3/8

500

19499

HDPE

5/8

1/2

100

Black High-

density

polyethylene

Required for

larger

diameter

NOTE

E-2