2 zero/span, Zero/span – Campbell Scientific CPEC200 Closed-Path Eddy-Covariance System User Manual

Page 32

CPEC200 Closed-Path Eddy-Covariance System

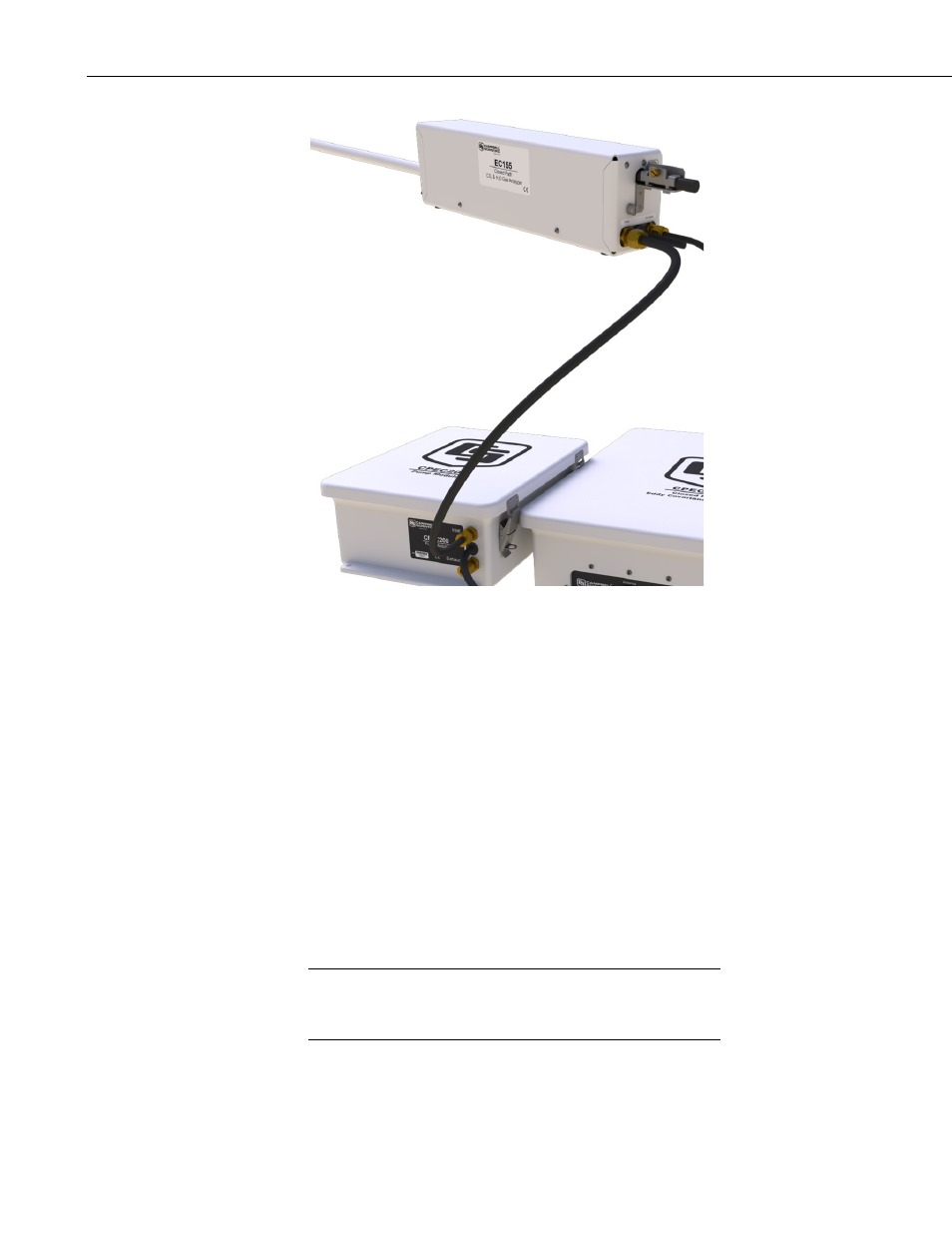

FIGURE 5-5. Connecting pump tube from EC155 analyzer to pump

module

5.2.2 Zero/Span

The CPEC200 can perform automated zero (CO

2

and H

2

O) and CO

2

span of

the EC155. In most cases the user must supply cylinders of zero air and CO

2

span gas with appropriate regulators. If the user has chosen the optional

CPEC200 scrub module, then no cylinder of zero air is required. The rest of

this section assumes the use of cylinders of compressed gas, but see Appendix

G, CPEC Scrub Module Installation, Operation and Maintenance, for details

on the scrub module. Install cylinders in close proximity to the CPEC200

system enclosure. Each cylinder must have a pressure regulator to control the

outlet pressure at 10 psig and must have a 1/4-in Swagelok

®

fitting on the

outlet. Connect regulators to the valve module inlets using 1/4-in OD tubing,

such as pn 15702, or pre-swaged tube assemblies (pn 21823-L). Minimize the

length of these tubes to reduce the equilibration time after the zero or CO

2

span

cylinder is selected. Refer to Appendix E, Using Swagelok

®

Fittings, for

information on installing and replacing Swagelok

®

fittings.

Flow meters and needle valves are not needed because the

CPEC200 valve module has a proportional-control valve to

actively control the flow of zero and span gas to the EC155.

NOTE

22