3 manual zero and span, 1 manually starting the zero/span sequence, 1 temperature control – Campbell Scientific CPEC200 Closed-Path Eddy-Covariance System User Manual

Page 45: Manual zero and span, Manually starting the zero/span sequence, Temperature control, 1. automatic zero/span sequence, On 6.3, N table, Table 6-1

CPEC200 Closed-Path Eddy-Covariance System

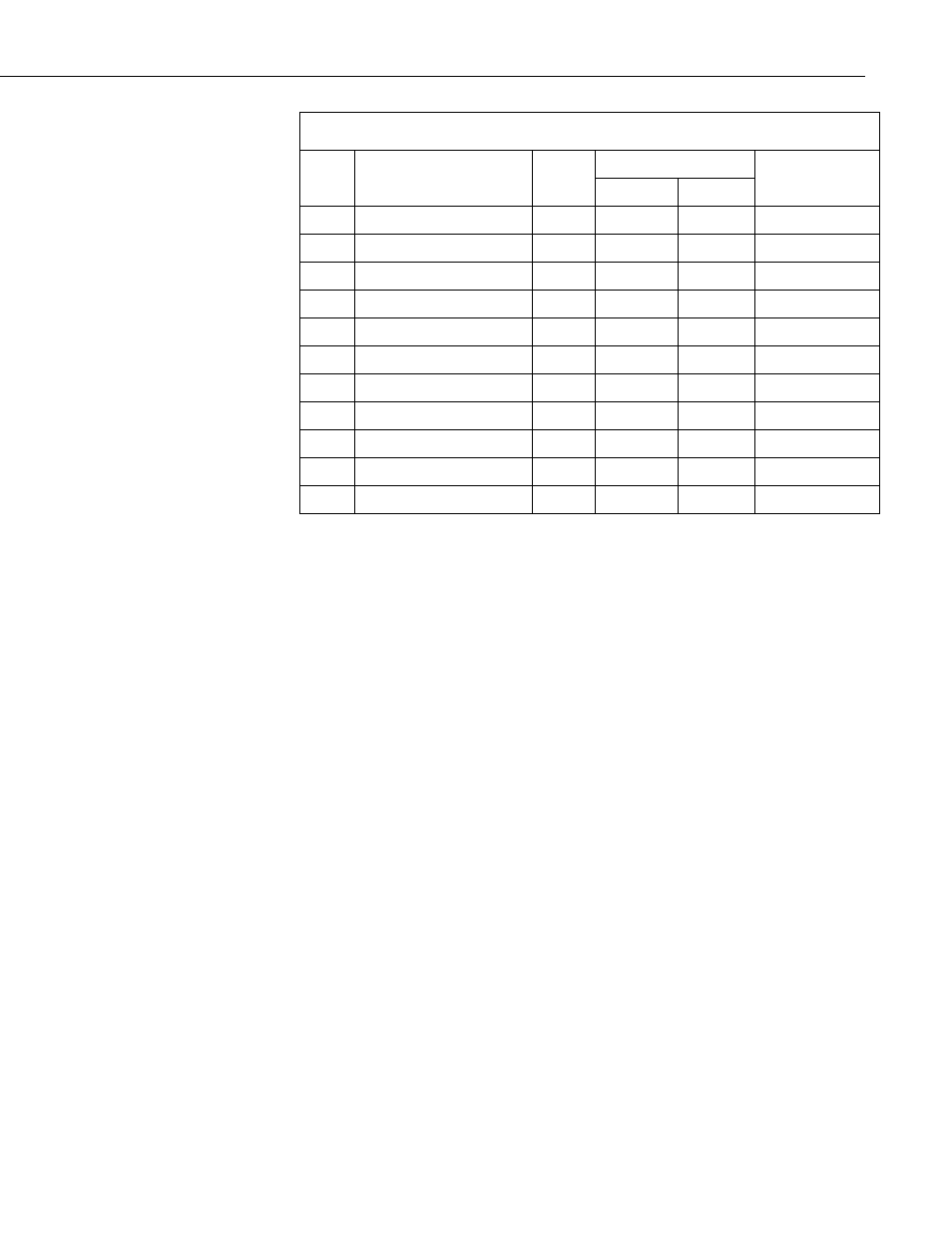

TABLE 6-1. Automatic Zero/Span Sequence

Step

Mode Status

Pump

valve_number

Duration (sec)

Keypad

Value

1

Measuring Pressure

Off

None

0

10

2

Checking CO2 Span 1

Off

CO2span1 2

SPAN_TIME

3

Checking Zero

Off

ZeroAir

1

ZERO_TIME

4

Setting Zero

Off

ZeroAir

1

10

5

Rechecking CO2 Span 1 Off

CO2span1 2

SPAN_TIME

6

Setting CO2 Span 1

Off

CO2span1 2

10

7

Checking CO2 Span 2

Off

CO2span2 3

SPAN_TIME

8

Checking CO2 Span 3

Off

CO2span3 4

SPAN_TIME

9

Checking CO2 Span 4

Off

CO2span4 5

SPAN_TIME

10

Equilibrating for EC

On

None

0

10

11

Switching to EC mode

On

None

0

0.1

6.3 Manual Zero and Span

There are two ways to manually zero/span the IRGA in the CPEC200:

1. The zero/span sequence may be run at any time by initiating the

sequence manually. This will often be the easiest way to do a manual

zero/span, but the sequence cannot do the H

2

O span. At the

completion of the sequence the system will automatically return to EC

mode.

2. The user may manually control each step in the zero/span process.

Using full manual control allows the H

2

O to be spanned. It also

bypasses some of the automated checking. For example, full manual

control will allow the user to do a zero or span even if there is a

diagnostic flag.

The two approaches to doing a manual zero/span are described below:

6.3.1 Manually starting the zero/span sequence

6.3.1.1 Temperature Control

Both the valve and scrub modules have heaters and fans to keep them within

their operating temperature range. Generally, this temperature control function

is disabled to conserve power. If the CPEC200 is configured for automatic

zero/span sequences, it will automatically enable temperature control of the

valve and scrub modules before the zero/span sequence is scheduled to begin.

This allows the valve module and scrub module to reach operating temperature

range even in very cold weather.

35