Pf3000 cotton yield monitor, Ag leader technology – Ag Leader PF3000 Cotton Yield Monitor Operators Manual User Manual

Page 21

PF3000 Cotton Yield Monitor

Ag Leader Technology

Vehicle Setup

March 2002

2-7

Flow Sensor

Configuration

Set the number of flow sensors installed on the picker. 2 rows is the default.

All rows will assign the appropriate number of sensors for each row. Cotton

strippers are fixed at 3 sets of sensors regardless of the number of rows

harvested.

Header Height

Set as either STANDARD or OPTIONAL. Standard is the only header

height sensor available at this time.

Area Count Stop

Beeps

The range for setting area count is 1 through 100. The default setting is 20.

This is the number of times the monitor beeps when the head is raised.

Fan

Pulses/Revolutions

Sets the number of pulses per revolution to correctly display fan speed on

the PF3000. The default setting for CASE-IH pickers is 30. For John Deere

pickers 16.

Primary and

Secondary Speed

Sensor

The monitor has four different primary speed settings. They are listed

below.

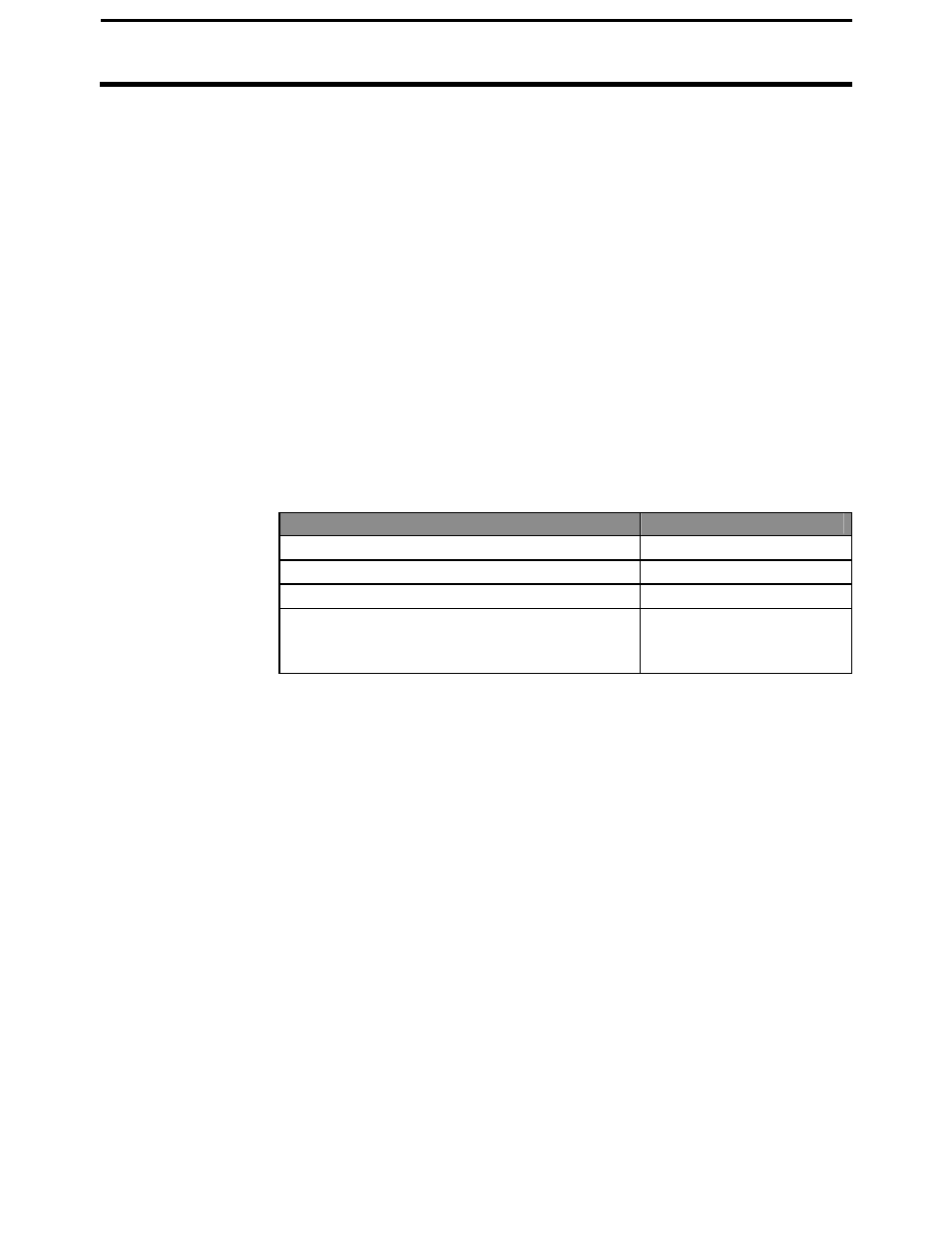

Ground Speed Sensor

Primary Speed Sensor

Speed sensor on transmission

WHEEL

Speed sensor on tracks

TRACK

Radar gun

RADAR

GPS receiver (must be rated for accurate

ground speed: GPS2000/2100, Add-On

GPS3000/3100 and Trimble AgGPS receivers)

GPS

If you choose GPS as your primary speed sensor, you need to set the

secondary speed sensor to WHEEL, TRACK, or RADAR. If the GPS signal

is lost, the monitor will use the secondary speed sensor. If you do not

choose GPS as your primary speed sensor you can not set the secondary

speed sensor.

Speed sensor pulses

/ 100 ft.

It is not recommended that you change this setting. This number is the

distance calibration number that is set when you perform a distance

calibration for WHEEL, TRACK or RADAR. Refer to the calibrating

distance instructions in the Calibration section. You must calibrate distance

for a WHEEL, TRACK or RADAR setting for accurate ground speed.