A2: temperature control, Appendix a2, E-m-hg2-s-v2.1 – ROTRONIC Hygrogen2 User Manual

Page 63

E-M-HG2-S-V2.1

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2 Humidity and Temperature Generator:

Instruction Manual

Appendix

Instruction Manual for Software

Version 2.1

Document Type

Page 59 of 75

Document title

Caution:

When tightening or releasing the Swagelok connectors do not apply torque to the nut/caps

without using a spanner on the connector body to counteract it. Finger tighten and then

apply a quarter turn with a spanner.

Replace the blanking caps when not using the sample loop.

If the chilled mirror instrument is being used in conjunction with a thermometer (in order to calculate

relative humidity), the temperature probe should be positioned in the chamber. Care should be taken

to ensure that insertion depth and stem conduction effects do not induce measurement errors.

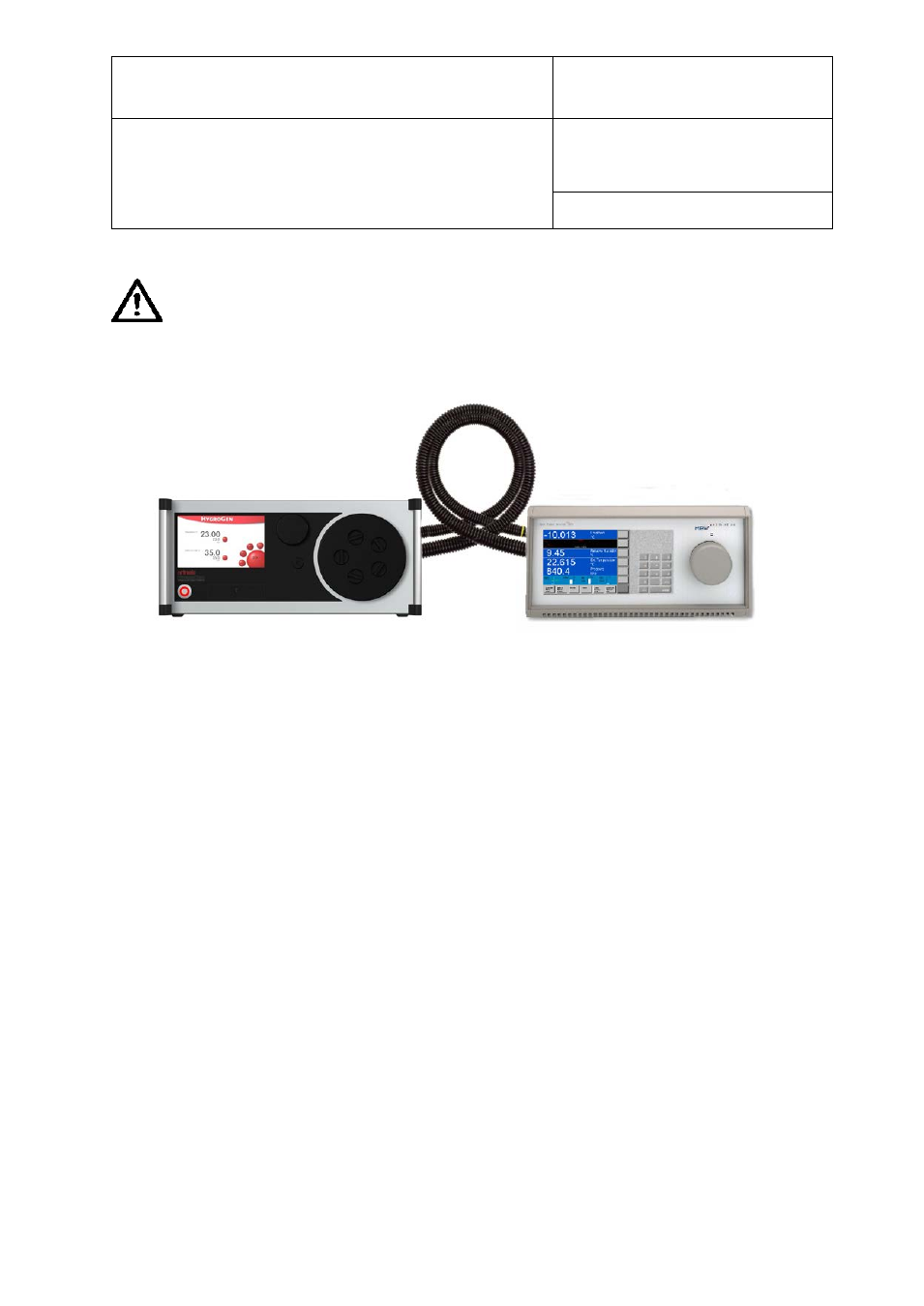

A typical HygroGen2/Chilled Mirror set up is shown at Figure 38; note the heated sample lines to the

rear.

Set the flow rate through the sample loop according the mirror instrument manufacturer’s

specifications. A lower flow rate will improve stability criteria but may influence measurement

response time.

A2: Temperature Control

Temperature control within the HygroGen2 is performed by a fast response PT100 thermometer

which is continuously referenced against the HygroClip control probe. The chamber is not considered

stable (as indicated by the control indicator being coloured green) unless the reported temperature

values are within the resolution of the control HygroClip.

If a replacement HygroClip reference is put into the HygroGen2, and it gives a significantly different

temperature reading, it may take a while - roughly 20 minutes for every 0.1°C discrepancy - the first

time stability control is engaged, as the self-adjustment algorithm runs.

Figure 38: HygroGen2/Chilled Mirror Set

© 2014; Rotronic AG

E-M-HG2-S-V2.1