E-m-hg2-s-v2.1 – ROTRONIC Hygrogen2 User Manual

Page 62

E-M-HG2-S-V2.1

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2 Humidity and Temperature Generator:

Instruction Manual

Appendix

Instruction Manual for Software

Version 2.1

Document Type

Page 58 of 75

Document title

Chilled mirror probes are convenient for dew point ranges above ambient as they are immersed in the

conditions and therefore condensation in sample lines need not be considered.

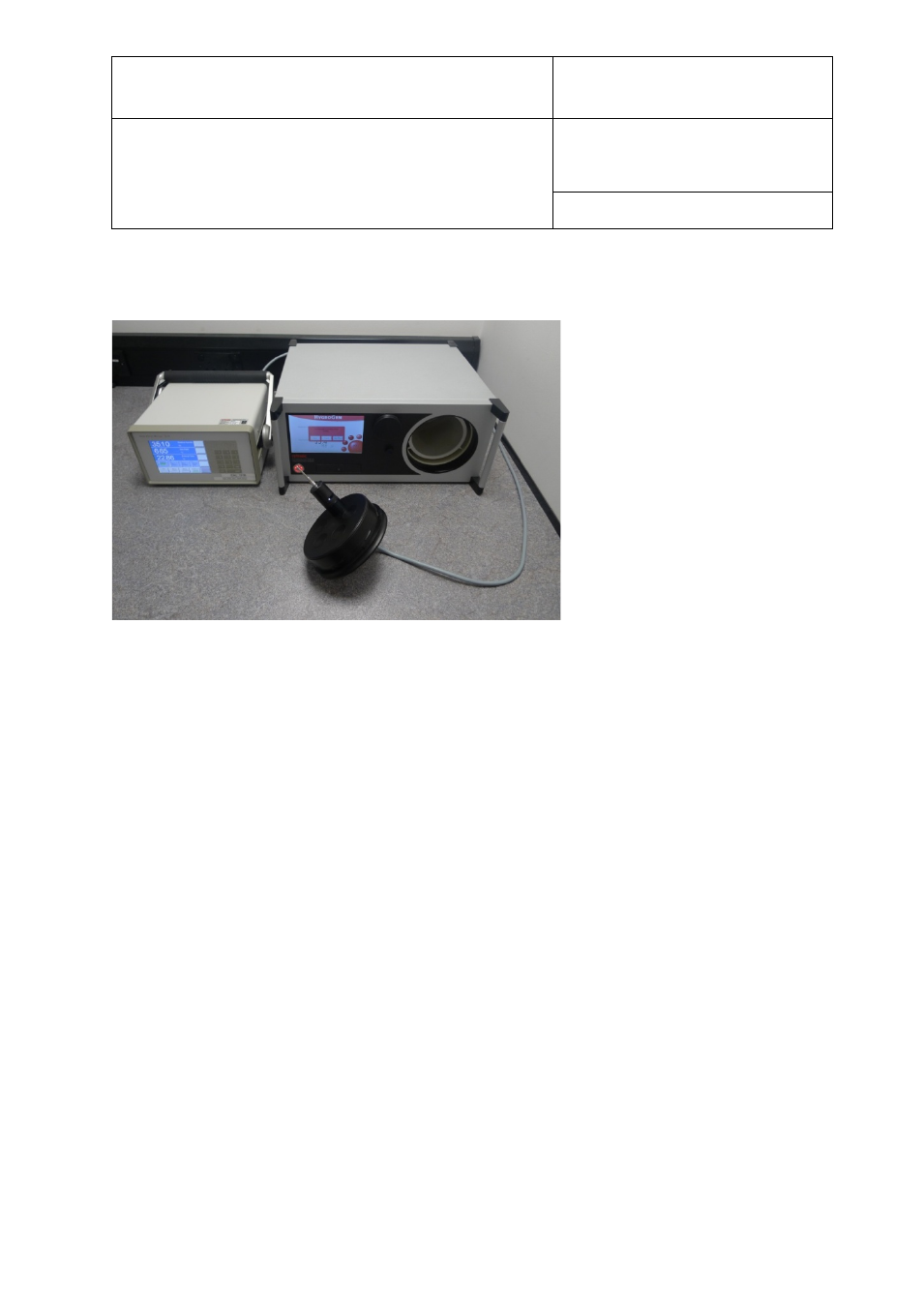

Figure 37: RP2 Head fully inserted into HygroGen2 door

Make sure the mirror is positioned so that moving air within the chamber flows over the mirror

surface.

External sample loop operation

To use a HygroGen2 with a chilled mirror that has an external sampling head, connect via the heated

sample loop points on the back panel (Figure 2, items 1 & 2). The HygroGen2 sample ports and internal

tubing are automatically controlled to 5°C above the chamber temperature to eliminate the possibility

of condensation formation.

The connecting lines to the mirror must also be heated if the set chamber conditions create a dew

point temperature higher than the ambient conditions. Make sure that your chilled mirror operating

capability is within the required range. For humidity values with a dew point below ambient

temperature, heated sample lines are not required.

Remove the blanking caps fitted to the sample loop Swagelok fittings and use nuts and olives to

connect the sample tubes from the chilled mirror. 6mm OD FEP or stainless tubing should be used to

connect the sample loop out and return ports to the chilled mirror unit. If the mirror instrument does

not have a built-in pump, flow meter and regulator, we recommend including these in the sample loop

(after the mirror) to confirm the air flow rate required by the chilled mirror instrument (typically

0.5l/min).

© 2014; Rotronic AG

E-M-HG2-S-V2.1