E-m-hg2-s-v2.1 – ROTRONIC Hygrogen2 User Manual

Page 57

E-M-HG2-S-V2.1

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal/AutoCal+, Remote Control and

Range Extensions options.

Instruction Manual

Instruction Manual for Software

Version 2.1

Document Type

Page 53 of 75

Document title

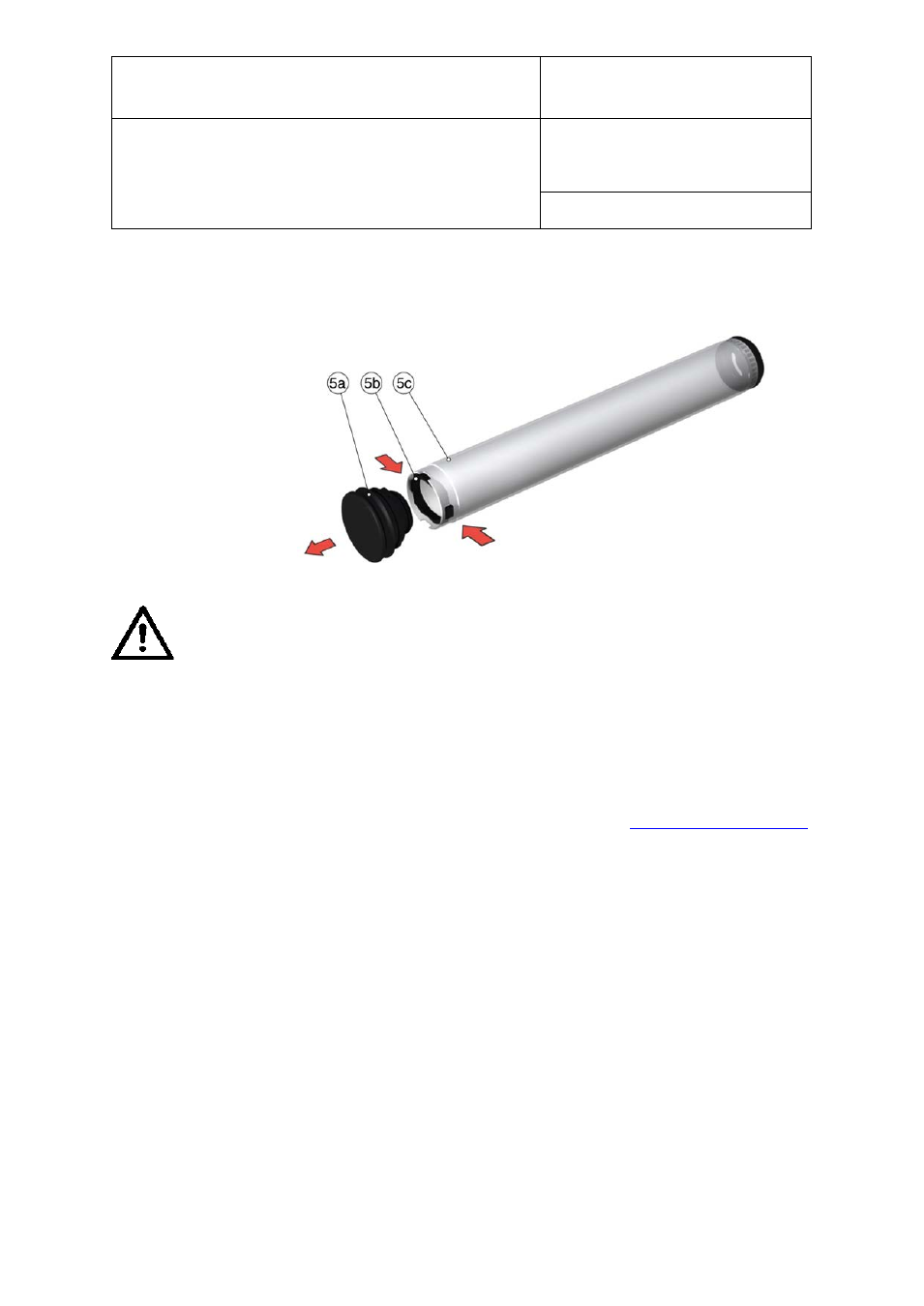

Ensure that the cell is filled with as much desiccant as possible to ensure there are no air gaps.

Remember to replace the foam insert (that fits between the cell cap and the desiccant) before

replacing the cell cap and spring clip. Application of silicone grease on the desiccant cell cap “O” ring

will help ease removal and refitting.

Caution: Do not use dusty desiccants as the dust may be passed into the chamber.

Choice of Desiccant

The HygroGen2 is supplied from the factory filled with molecular sieve desiccant. Molecular sieve is

preferred due to its higher performance in all temperature and humidity conditions and is longer

lasting and can be regenerated through heating. Other desiccants including self-indicating silica gel

and drierite can be used if desired; for further information, please contact

Dusty desiccants should be avoided as particles may be passed into the HygroGen2 chamber. Replace

or regenerate the desiccant whenever the drying performance of the HygroGen2 is deteriorating.

Material Safety Sheets for the desiccants supplied by ROTRONIC are available on request.

Regeneration of Molecular Sieve Desiccant

To regenerate molecular sieve, remove it from the desiccant cell and heat it at 175°C for 3-5 hours in

a dry environment (do not use a gas oven). After heating, allow to cool in a dry or sealed environment.

Performance of the regenerated desiccant can be measured in the HygroGen2 according to the

method described above. Alternatively, replacement new desiccant can be ordered from ROTRONIC.

Please contact your local dealer.

5a) Cell cap

5b) Retaining clip

5c) Cell body

Figure 36: Desiccant Cell

© 2014; Rotronic AG

E-M-HG2-S-V2.1