ROTRONIC HM4 User Manual

ROTRONIC Tools

12

.0

82

3.0

10

2

ROTRONIC AG, CH-8303 Bassersdorf

Tel. +41 44 838 11 44, www.rotronic.com

ROTRONIC Messgeräte GmbH, D-76275 Ettlingen

Tel. +49 7243 383 250, www.rotronic.de

ROTRONIC SARL, 56, F - 77183 Croissy Beaubourg

Tél. +33 1 60 95 07 10, www.rotronic.fr

ROTRONIC Italia srl

,

I- 20157 Milano

Tel. +39 2 39 00 71 90, www.rotronic.it

ROTRONIC Instruments (UK) Ltd, West Sussex, RH10 9EE

Phone +44 1293 571000, www.rotronic.co.uk

ROTRONIC Instrument Corp, NY 11788, USA

Phone +1 631 427-3898, www.rotronic-usa.com

ROTRONIC Instruments Pte. Ltd., Singapore 159836

Phone +65 6376 2107, www.rotronic.sg

ROTRONIC Shanghai Rep. Offi ce, Shanghai 200233, China

Phone +86 40 08162018, www.rotronic.cn

A

Congratulations on your new state-of-the-art HygroMet4. Please read these short instructions

carefully before installing the device.

These short instructions are limited to a description of the main functions and installation of the

device. The detailed instruction manual can be found on the internet at:

www.rotronic.com

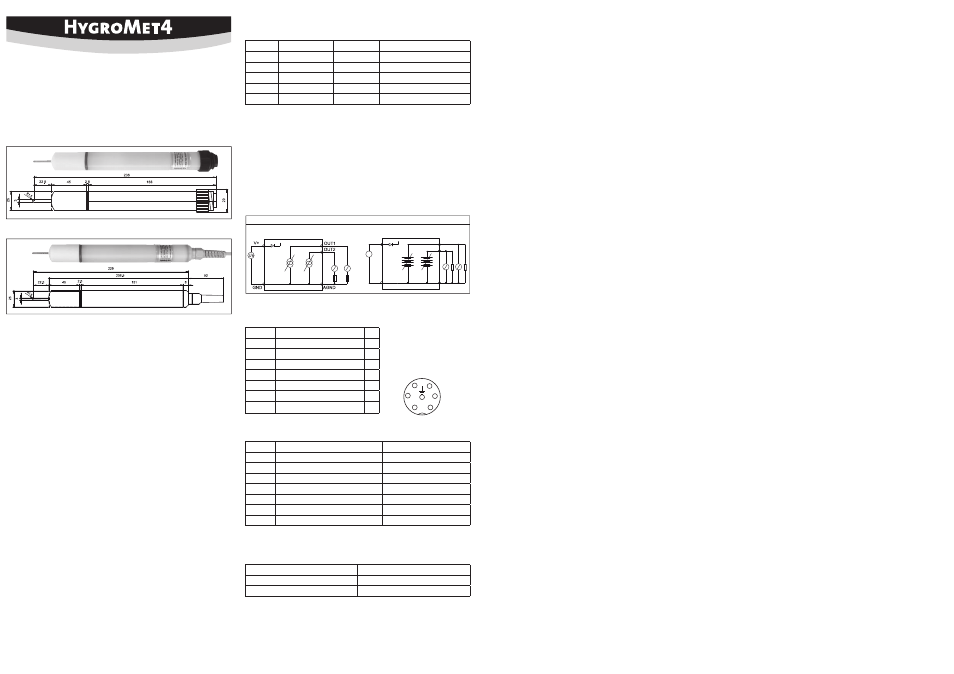

HygroMet4 Tuchel

HygroMet4 Cable (with Tuchel)

Introduction

The meteorological probes in the HygroMet4 series are transmitters for relative humidity and

temperatute. The humidity is measured with heated sensors. Heating of the humidity sensor

enables the following properties / functions:

• elimination of thawing

• sensor cleaning

Mechanical Installation

General Recommendations

Relative humidity is temperature-dependent. In order to measure it exactly, the probes and

sensors must be set exactly on the temperature level of the environment that is to be measured.

The installation site can therefore have a signifi cant infl uence on the performance of the device.

Follow the guidelines below to ensure optimum performance:

a) Select a representative installation site: Install the probe at a point where the humidity,

temperature and pressure conditions are representative for the environment that is to be

measured.

b) Ensure there is suffi cient air movement at the probe: An air velocity of at least 1 meter per

second accelerates and facilitates adaptation of the probe to changing temperatures.

SHORT INSTRUCTION MANUAL

Pin Confi guration / Wiring Diagram

Analog Outputs and GND

To prevent measurement errors, analog ground AGND must also be used for the

analog outputs.

A

Current Output

Diagram

V+

GND

OUT2

OUT1

AGND

U

B

Voltage Output

HygroMet4 Tuchel

At housing or remote with cable

Description

PIN

V +

Power supply +

1

GND

Power supply GND

2

AGND

Analog signals GND

3

OUT2

Analog output 2:

Temperature

4

RS-485 +

RS-485 +

5

OUT1

Analog output 1:

Humidity

6

RS-485 −

RS-485 −

R

HygroMet4 Cable

Description

Wire Color

V +

Power supply +

Green

GND

Power supply GND

Gray / Shield

AGND

Analog signals GND

Yellow

OUT2

Analog output 2:

Temperature

Brown

RS-485 +

RS-485 +

Red

OUT1

Analog output 1:

Humidity

White

RS-485 −

RS-485 −

Blue

Service Cable

Depending on the version of HygroMet4 different cables need to be used:

For HygroMet4

Service Cable

With cable and open ends

AC3010

Tuchel connector direct or extended with cable AC3010-T

Solder Side

2

3

4

5

6

1

Scaling / Adjustment / Firmware Update

The following settings can be made using the HW4 software and correct service cable:

• new scaling of the outputs

• fi rmware update

• adjustment of the probe

• setting of the heater and sensor cleaning

Programming

The basic settings of the devices are made in the factory according to your order. The transmitters

are adjusted in the factory and therefore do not need to be checked and readjusted during instal-

lation. The devices can be started immediately after installation.

Periodic Calibration of the Probe

Both the temperature sensor and the corresponding electronics are very stable and do not normally

need to be changed or calibrated after factory calibration.

The long-term stability of the ROTRONIC SMD thermo sensor is typically better than 1 %RH per year.

For maximum accuracy we recommend calibration of the probe about every six to 12 months. More

frequent calibration can be necessary in applications where the sensor is exposed to pollutants.

The calibration can be performed by the user himself on site or in the laboratory / workshop. For

routine calibrations the probe should be checked at one or two points.

For all further details on calibration, please see the full version of the instruction manual, which

you can download from the internet.

Filter Cleaning

The fi lter can become soiled by dust in the air and must be replaced periodically.

Technical Data (Operation)

Humidity:

0...100 %RH

Temperature

– 40...85 °C

Accuracy humidity

heated: 1.5 %RH

Accuracy temperature

0.1 °C

Supply voltage

(5) 15...24 VDC depending on type

Rated current consumption

With sensor heating

<55 mA at V+ = 5 VDC

<30 mA at V+ = 24 VDC

Without sensor heating

<35 mA at V+ = 5 VDC

<20 mA at V+ = 24 VDC

Protection:

IP65

Accessories & Spare Parts

Art. No.:

Description

AC3010

Service cable for connection of cables with open ends

AC3010-T

Service cable for connection of a Tuchel connector

NSP-25-PE

Polyethylene (replacement) fi lter

EM-25-HM

Calibration device for Ø 25 mm HygroMet probes

EAXX-SCS

Humidity standard XX = 00,05,10,11,20,34,50,60,65,75,80,95 %RH

Electrical Installation

Power Supply

Type

Analog Outputs

Digital

Power Supply

HM431

0...20 mA

RS-485

15...24 VDC

HM432

4...20 mA

RS-485

15...24 VDC

HM433

0...1 VDC

RS-485

5...24 VDC

HM434

0...5 VDC

RS-485

15...24 VDC

HM435

0...10 VDC

RS-485

15...24 VDC

Caution: Wrong supply voltages and excessively high loading of the outputs can

damage the transmitter.