A.O. Smith HW 610 User Manual

Page 21

21

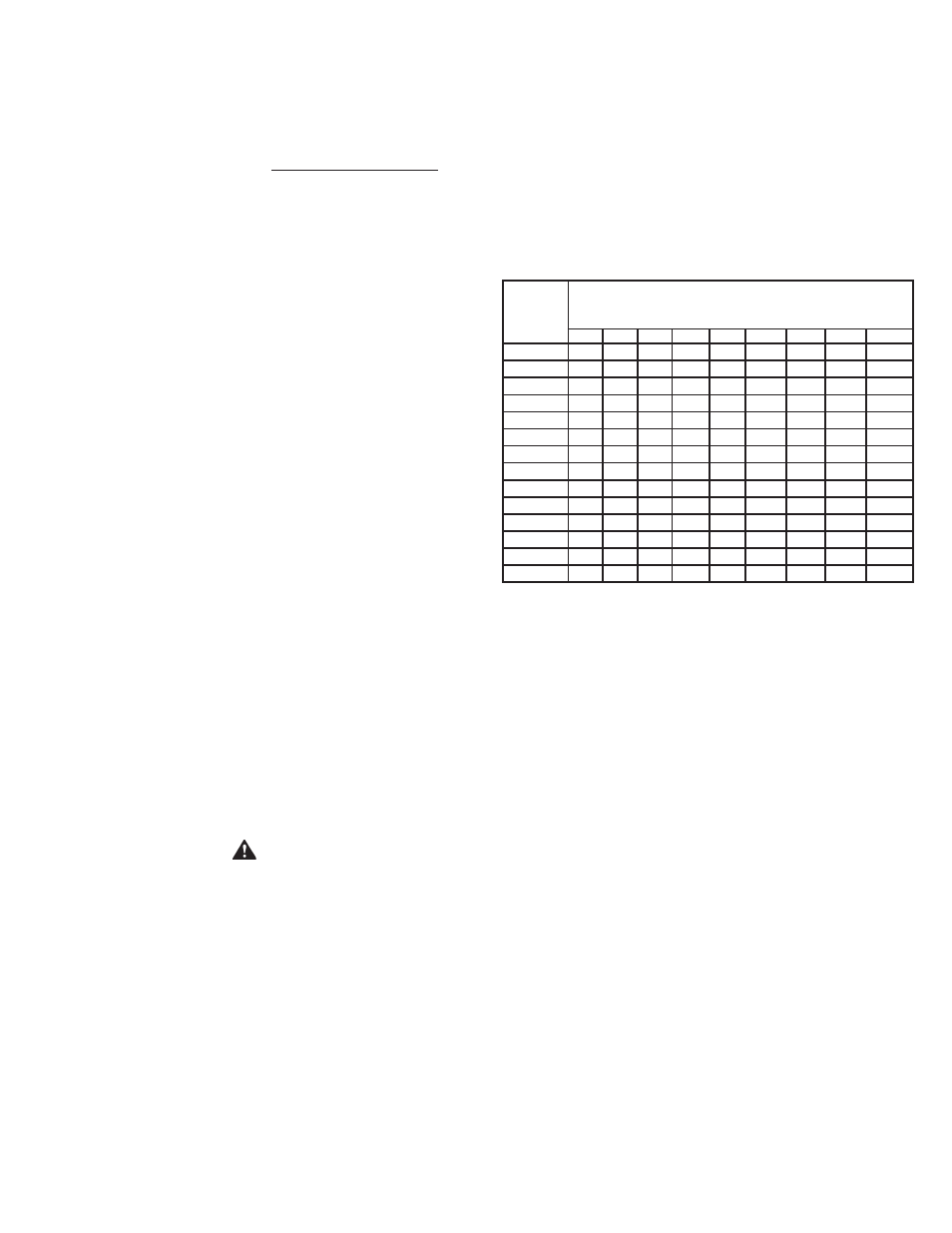

Use table 7, or CAN/CSA B149.1 (current edition) to

size iron pipe or equivalent gas supply line. Table 7

is based on a pressure drop of 0.3 inches of water and

a specific gravity of 0.60 approximately that of natural

gas. (LP gas has an S.G. of about 1.53). If the service pressure

is five inches water column or less, use one pipe size larger in

order to minimize pressure drop in the line.

TABLE 7.

MAXIMUM CAPACITY OF PIPE IN CUBIC FEET OF GAS PER

HOUR (BASED UPON A PRESSURE DROP OF 0.3 INCH

WATER COLUMN AND 0.6 SPECIFIC GRAVITY GAS)

Distance

from Gas

Meter

Nominal Iron Pipe Size (Inches)

1/2

3/4

1

1 1/4 1 1/2

2

2 1/2

3

4

10 (3)

132 278 520 1,050 1,600 3,050 4,800 8,500 17,500

20 (6)

92

190 350 730 1,100 2,100 3,300 5,900 12,000

30 (9)

73

152 285 590

890 1,650 2,700 4,700 9,700

40(12)

63

130 245 500

760 1,450 2,300 4,100 8,300

50 (15)

56

115 215 440

670 1,270 2,000 3,600 7,400

60 (18)

50

105 195 400

610 1,150 1,850 3,250 6,800

70 (21)

46

96

180 370

560 1,050 1,700 3,000 6,200

80 (24)

43

90

170 350

530

990 1,600 2,800 5,800

90 (27)

40

84

160 320

490

930 1,500 2,600 5,400

100 (30)

38

79

150 305

460

870 1,400 2,500 5,100

125 (38)

34

72

130 275

410

780 1,250 2,200 4,500

150 (45)

31

64

120 250

380

710 1,130 2,000 4,100

175 (53)

28

59

110 225

350

650 1,050 1,850 3,800

200 (60)

26

55

100 210

320

610

980 1,700 3,500

*The heating value of Natural Gas is approximately 1,050 Btu/Ft

.3

.

Propane (LP) Gas has a heating value of approximately 2,500 Btu/Ft

3

.

1 cu. meter=35.31 cu. feet.

Where it is necessary to use more than the average number of pipe

fittings i.e. elbows, tees, and valves in gas supply line, use a pipe

larger than specified to compensate for increased pressure drop.

2B. SIZING GAS SUPPLY LINE (For multiples of over three boilers of

same size or for multiple installations of two or more mixed sizes).

Capacities in cubic feet per hour of 0.60 specific gravity gas for

different sizes and lengths are shown in table 7. No additional

allowance is necessary for an ordinary number of fittings.

Applications of the gravity factor converts the figures given in table

7 to capacities with another gas of different specific gravity. Such

application is accomplished by multiplying the capacities given in

table 7 by the multipliers shown in table 8 on page 22.

To determine the size of each section of gas piping in a system within

the range of table 7 proceed as follows:

• Determine the gas demand of each appliance to be attached

to the piping system. When table 7 is to be used to select the

piping size, calculate the gas demand in terms of cubic feet

per hour for each piping system outlet. The gas demand for

an appliance can be found by dividing its heat input rate by

the gas’s heating value.

• Obtain or determine the length of piping from the gas meter or

service regulator to the appliance(s).

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS

SUPPLY LINE, A DIRT LEG (SOMETIMES CALLED DRIP

LEG or sediment trap) MUST BE INCORPORATED IN THE

PIPING, see Figure 1 on page 6. The dirt leg must be readily

accessible and not subject to freezing conditions. INSTALL IN

ACCORDANCE WITH RECOMMENDATIONS OF SERVING

GAS SUPPLIERS. (Refer to National Fuel Gas Code, ANSI

Z223.1 or CAN/CSA-B 149.1 Installation Codes.

To prevent damage, care must be taken not to apply too

much torque when attaching gas supply pipe to the gas valve

gas inlet.

Fittings and unions in the gas line must be the metal to

metal type.

Apply joint compounds (pipe dope) sparingly and only to the

male threads of pipe joints. Do not apply compound to the first

two threads. Use compounds resistant to the action of liquefied

petroleum gases.

THE BOILER AND ITS GAS CONNECTIONS MUST BE LEAK

TESTED BEFORE PLACING THE BOILER IN OPERATION.

Use soap and water solution or other material acceptable for

the purpose in locating gas leaks. DO NOT USE MATCHES,

CANDLES, FLAME OR OTHER SOURCES OF IGNITION FOR

THIS PURPOSE.

DISCONNECT THE BOILER AND ITS MAIN MANUAL

GAS SHUTOFF VALVE FROM THE GAS SUPPLY PIPING

SYSTEM DURING ANY PRESSURE TESTING OF THE GAS

SUPPLY SYSTEM OVER 1/2 PSIG (3.5kPa). THE GAS SUPPLY

LINE MUST BE CAPPED WHEN NOT CONNECTED TO

THE BOILER.

THE BOILER MUST BE ISOLATED FROM THE GAS SUPPLY

PIPING SYSTEM BY CLOSING ITS MAIN MANUAL GAS

SHUTOFF VALVE DURING ANY PRESSURE TESTING OF

THE GAS SUPPLY PIPING SYSTEM AT TEST PRESSURES

EQUAL TO OR LESS THAN 1/2 PSIG (3.5kPa).

PURGING AND SIZING

Gas line purging is required with new piping or systems in which

air has entered.

CAUTION

PURGING SHOULD BE PERFORMED BY PERSONS

EXPERIENCED IN THIS TYPE GAS SERVICE TO AVOID RISK OF

FIRE OR EXPLOSION. PURGE DISCHARGE MUST NOT ENTER

CONFINED AREAS OR SPACES WHERE IGNITION CAN OCCUR.

THE AREA MUST BE WELL VENTILATED AND ALL SOURCES OF

IGNITION MUST BE INACTIVATED OR REMOVED.

1. CORRECT GAS

Make sure the gas on which the boiler will operate is the same as

that specified on the boiler rating plate. Do not install the boiler if

equipped for a different type gas — consult your supplier.

2A. SIZING GAS SUPPLY LINE (For single boiler installations

and for installations of multiples of two or three of same

size boilers).