A.O. Smith HW 610 User Manual

Page 10

10

CAUTION

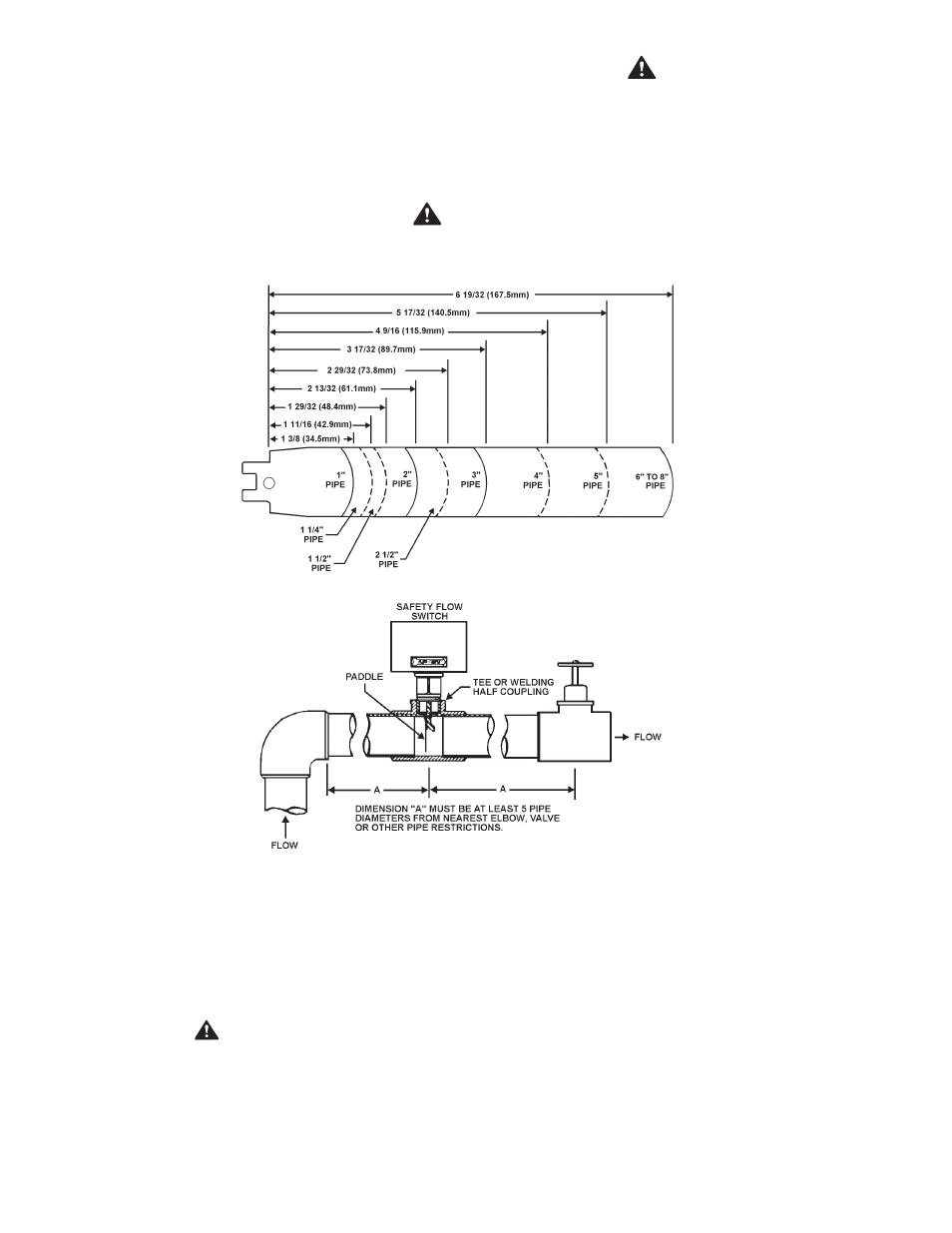

Paddle must be trimmed at the dotted arc. It must not touch the pipe or have any restriction when installed.

FIGURE 6.

To adjust the flow rate setting:

1. Remove the flow switch cover.

2. For higher flow rate - turn the range adjusting screw clockwise.

3. For lower flow rate - turn the range adjusting screw

counterclockwise.

CAUTION

The switch is factory set at approximately the minimum flow rate, see

Table 3 on page 9. It must not be set lower than the factory setting as

this may result in the switch failing to return at 'no flow' condition.

4. Replace flow switch cover. Where units are installed in multiples,

each boiler must be individually protected by a safety flow switch.

SAFETY RELIEF VALVES

Your local code authority may have other specific relief valve

requirements not covered below.

WARNING

THE PURPOSE OF A SAFETY RELIEF VALVE IS TO AVOID

EXCESSIVE PRESSURE OR TEMPERATURE INTO THE STEAM

RANGE WHICH MAY CAUSE SCALDING AT FIXTURES, TANK

EXPLOSION, SYSTEM OR BOILER DAMAGE.

TO AVOID SCALDING OR WATER DAMAGE A DRAIN LINE MUST

BE CONNECTED TO A RELIEF VALVE TO DIRECT DISCHARGE

TO A SAFE LOCATION. A DRAIN LINE MUST NOT BE REDUCED

FROM THE SIZE OF THE VALVE OUTLET AND IT MUST NOT

CONTAIN ANY VALVES BETWEEN THE BOILER AND THE

RELIEF VALVE OR THE RELIEF VALVE AND THE DRAIN EXIT.

IN ADDITION, THERE SHOULD NOT BE ANY RESTRICTIONS

IN A DRAIN LINE NOR SHOULD IT BE ROUTED THROUGH

AREAS WHERE FREEZING CONDITIONS MIGHT OCCUR. DO

NOT THREAD OR CAP THE DRAIN LINE EXIT. RESTRICTING

OR BLOCKING A DRAIN LINE WILL DEFEAT THE PURPOSE OF

THE RELIEF VALVE AND MAY CREATE AN UNSAFE CONDITION.

INSTALL A DRAIN LINE WITH A DOWNWARD SLOPE SUCH THAT

IT NATURALLY DRAINS ITSELF.

If any safety relief valve is replaced, the replacement valve must comply

with the current editions of the ASME Boiler and Pressure Vessel