Gas connections – A.O. Smith HW 610 User Manual

Page 20

20

5. VENT VALVES

It is recommended that automatic, loose key or screwdriver type

vent valves be installed at each convector or radiator.

6. MANIFOLD HEADERS

Split systems with individual supply and return lines from the boiler

room should normally have this piping connected to supply and

return manifold headers near the boiler. To achieve good water

distribution with maximum pressure drop for several circuits,

manifolds of at least 2-1/2" (64mm) diameter are suggested on

HW-399, HW-420, HW-520, HW-610 and HW-670 units. HW-300

units should have 1-1/2" (38mm) diameter manifolds.

The circuits should be spaced on the header at a minimum of

3" (76mm) center to center. Install a balancing cock in each return line.

Manifold headers are recommended for split systems with or without

zone valves and also those installations with zone circulators. If the

system is to be split at remote points, good practice requires special

attention be given to main pipe sizing to allow balancing of water flow.

The boiler piping system of a hot water boiler connected to heating

coils located in air handling units where they may be exposed to

refrigerated air circulation must be equipped with flow control valves or

other automatic means to prevent gravity circulation of the boiler water

during the cooling cycle.

7. COOLING PIPING

When the boiler is used in conjunction with a refrigeration system it

must be installed so that the chilled medium is piped in parallel with

the boiler with appropriate valves to prevent the chilled medium from

entering the boiler, see Figure 13.

Water temperature in the heating system must be reduced to less

than 100

0

F (38°C) before cooling system is started, or damage to

the chiller unit may occur.

SCHEMATIC SHOWING PROPER PIPING ISOLATION

OF THE BOILER FROM THE CHILLER

FIGURE 13.

If the boiler is connected to chilled water piping or its heating coils

are exposed to refrigerated air, the boiler piping system must be

equipped with flow valves or other automatic means to prevent gravity

circulation through the boiler during the cooling cycle.

8. CIRCULATING PUMP

CONSTANT CIRCULATING PUMP OPERATION OF THE BOILER

VOIDS THE WARRANTY. Constant water flow through the unit

will “wash” away the copper’s natural protective coating. This is

called velocity erosion. This erosion is not as great a problem when

intermittent circulating operation is used per the recommended

installation procedure. Constant circulation of water through the

building’s system main is permissible as long as the water does not

constantly flow through the boiler. Only all bronze or stainless steel

circulators are to be used with the unit when it is installed in HOT

WATER SUPPLY SYSTEMS.

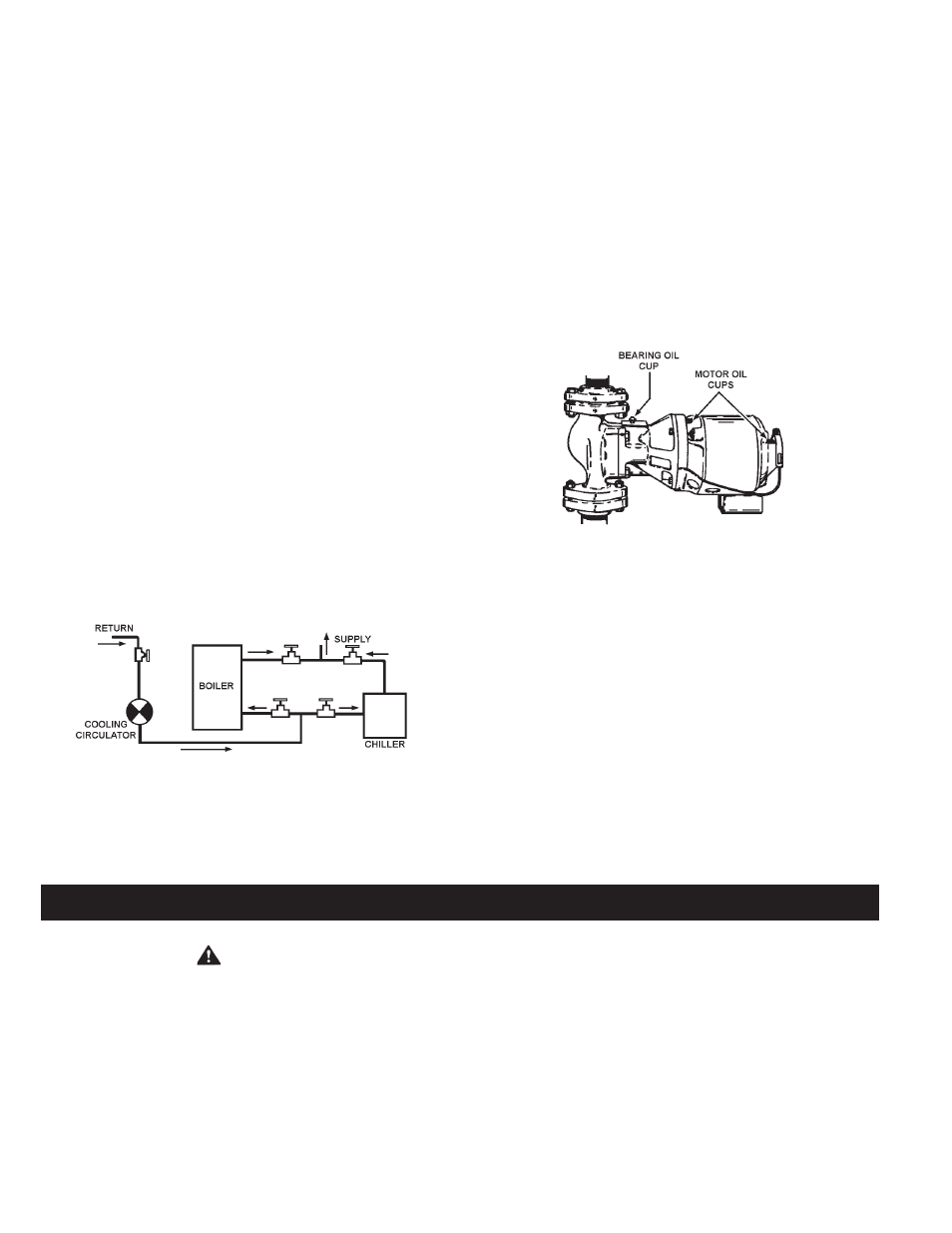

A TYPICAL CIRCULATING PUMP

FIGURE 14.

Although each circulator that requires oiling is oiled and operated by

the manufacturer, IT MUST BE OILED AGAIN BEFORE OPERATED.

Oil the three oil cups (2 on the motor, 1 on the pump) as instructed

on the oil tube supplied with the unit, see Figure 14 on this page.

Thereafter, during the heating season, lubricate the three oil cups at

least once every four months. Combination heating-cooling systems

should be lubricated every four months year ‘round.

Use 2 or 3 teaspoonsful in bearing oil cups or 12 drops in the motor

oil cups, see Figure 14 on this page. Use No. 20 non-detergent

motor oil.

Follow the same oiling procedure if a replacement circulator is

installed into the system.

GAS CONNECTIONS

WARNING

THIS BOILER IS NOT INTENDED TO OPERATE AT GAS SUPPLY

PRESSURE OTHER THAN SHOWN ON THE RATING PLATE.

EXPOSURE TO HIGHER GAS SUPPLY PRESSURE MAY CAUSE

DAMAGE TO GAS VALVES WHICH CAN RESULT IN FIRE OR

EXPLOSION. IF OVERPRESSURE HAS OCCURRED SUCH AS

THROUGH IMPROPER TESTING OF GAS LINES OR EMERGENCY

MALFUNCTION OF THE SUPPLY SYSTEM, THE GAS VALVES MUST BE

CHECKED FOR SAFE OPERATION. MAKE SURE THAT THE OUTSIDE

VENTS ON THE SUPPLY REGULATORS AND THE SAFETY VENT

VALVES ARE PROTECTED AGAINST BLOCKAGE. THESE ARE PARTS

OF THE GAS SUPPLY SYSTEM, NOT THE BOILER. VENT BLOCKAGE

MAY OCCUR DURING ICE BUILD-UP OR SNOW STORMS.

WHEN LOCAL CODES REQUIRE A MAIN MANUAL SHUTOFF

VALVE OUTSIDE THE BOILER JACKET, A SUITABLE MAIN

MANUAL SHUTOFF VALVE MUST BE INSTALLED IN A LOCATION

COMPLYING WITH THOSE CODES.

IT IS IMPORTANT TO GUARD AGAINST GAS VALVE FOULING

FROM CONTAMINANTS IN THE GAS WAYS. SUCH FOULING

MAY CAUSE IMPROPER OPERATION, FIRE OR EXPLOSION.

IF COPPER SUPPLY LINES ARE USED THEY MUST BE

CERTIFIED FOR GAS SERVICE.

BEFORE ATTACHING THE GAS LINE BE SURE THAT ALL GAS

PIPE IS CLEAN ON THE INSIDE.