General – A.O. Smith HW 610 User Manual

Page 12

12

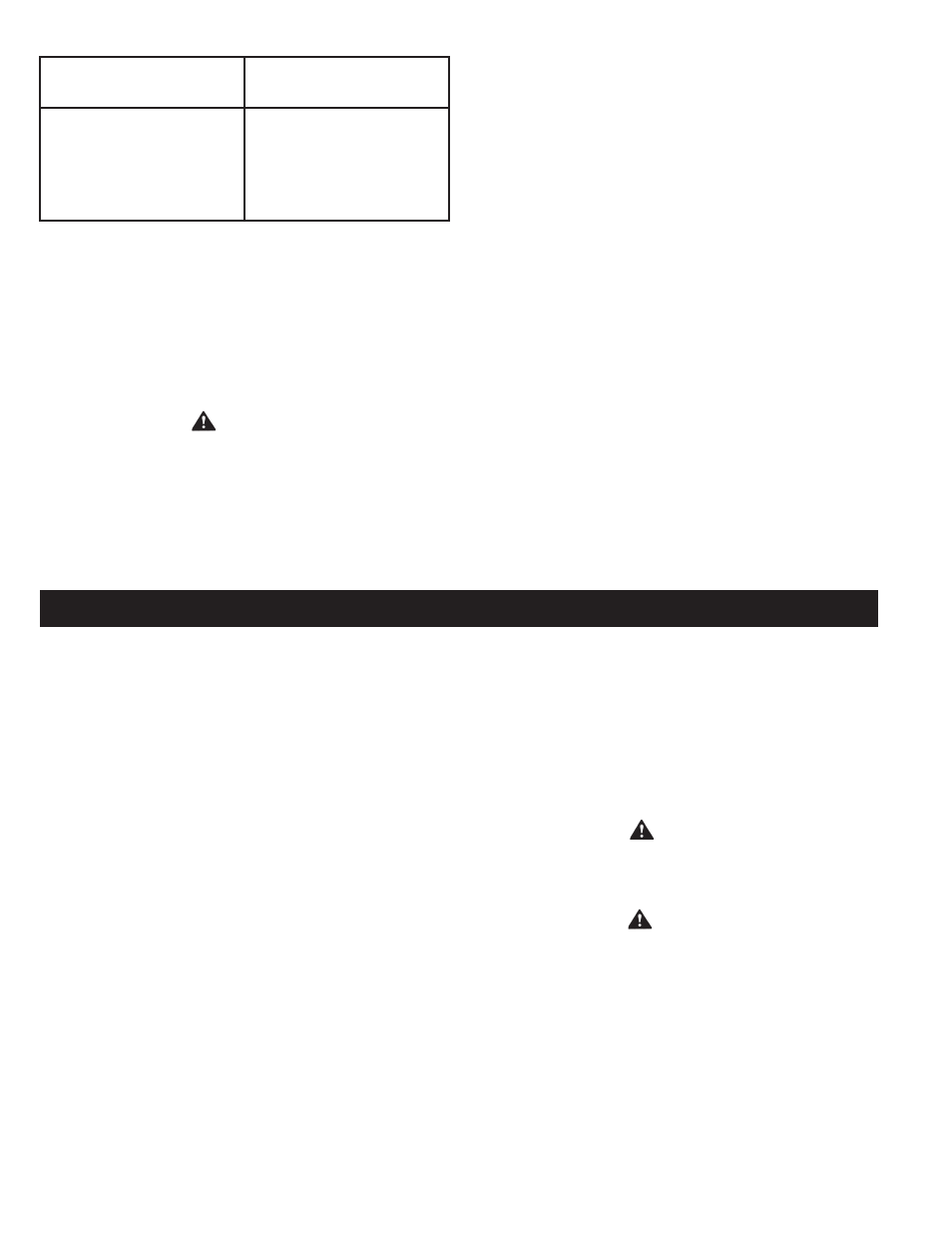

Water Temperature

Time to Produce 2nd & 3rd

Degree Burns on Adult Skin

OVER: 170°F (77°C)

160°F (71°C)

150°F (65°C)

140°F (60°C)

130°F (54°C)

120°F (49°C)

Nearly Instantaneous

About 1/2 second

About 1-1/2 seconds

Less than 5 seconds

About 30 seconds

More than 5 minutes

USE ANTI-SCALD VALVE(S) in the hot water system to reduce

the risks of scalds at points of use such as lavatories, sinks

and bathing facilities.

A change in water temperature in the storage tank lower than

the Tank Temperature Control setting will cause the sensor to

close its contacts and consequently energize the boiler.

If the Tank Temperature Control is out of calibration, replace it

with a new one; do not attempt to fix this control.

WARNING

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL

TO SHUT OFF, TURN OFF THE MANUAL GAS CONTROL

VALVE TO THE APPLIANCE.

GENERAL

THERMOMETERS

Thermometers should be obtained and field installed as shown

in the installation diagrams.

Thermometers are installed in the system as a means

of detecting a possible liming condition in the boiler.

An increase of 5°F (3°C) over the normal temperature

rise through the boiler is an indication that lime is

p r e s e n t . T h e t e r m " t e m p e r a t u r e r i s e " d e s i g n a t e s

the difference between the boiler inlet and outlet water

temperature.

An increase of 5°F (3°C) above the recorded temperature

rise may signify a liming condition in the coils or heat

e x c h a n g e r. R e f e r t o C L E A N I N G A N D F L U S H I N G

section of this manual for deliming instructions.

Record temperature rise at initial star t-up for future

reference.

DRAIN VALVE (Not Supplied)

A drain valve must be obtained and installed on each boiler

and tank for draining purposes, see installation diagrams in

this manual.

REQUIRED ABILITY

Installation or service of this boiler requires ability equivalent to that

of a licensed tradesman in the field involved. Plumbing, air supply,

venting, gas supply and electrical work are required.

LOCATION

When installing the boiler, consideration must be given to proper

location. Location selected should be as close to the stack or chimney

as practicable with adequate air supply and as centralized with the

piping system as possible. This location should also be such that the

gas ignition system components are protected from water (dripping,

spraying, etc.) during appliance operation and service (circulator

replacement, control replacement, etc.).

THE BOILER MUST NOT BE INSTALLED ON CARPETING.

THE BOILER SHOULD NOT BE LOCATED IN AN AREA WHERE

IT WILL BE SUBJECT TO FREEZING.

LOCATE IT NEAR A FLOOR DRAIN. THE BOILER SHOULD BE

LOCATED IN AN AREA WHERE LEAKAGE FROM THE BOILER OR

CONNECTIONS WILL NOT RESULT IN DAMAGE TO THE ADJACENT

AREA OR TO LOWER FLOORS OF THE STRUCTURE.

WHEN SUCH LOCATIONS CANNOT BE AVOIDED, A METAL

DRAIN PAN SHOULD BE INSTALLED UNDER THE BOILER. Such

pans should be fabricated with sides at least 60mm (2-1/2") deep,

with length and width at least 50mm (2") greater than the diameter

of the boiler and must be piped to an adequate drain. The pan must

not restrict combustion air flow.

WARNING

KEEPING BOILER AREA CLEAR AND FREE FROM COMBUSTIBLE

MATERIALS, GASOLINE AND OTHER FLAMMABLE VAPORS AND

LIQUIDS.

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES

SUCH AS BOILERS IN ROOMS OR AREAS WHERE GASOLINE,

OTHER FLAMMABLE LIQUIDS OR ENGINE DRIVEN EQUIPMENT

OR VEHICLES ARE STORED, OPERATED OR REPAIRED.

FLAMMABLE VAPORS ARE HEAVY AND TRAVEL ALONG THE

FLOOR AND MAY BE IGNITED BY THE IGNITER OR MAIN BURNER

FLAMES CAUSING FIRE OR EXPLOSION. SOME LOCAL CODES