A.O. Smith HW 610 User Manual

Page 16

16

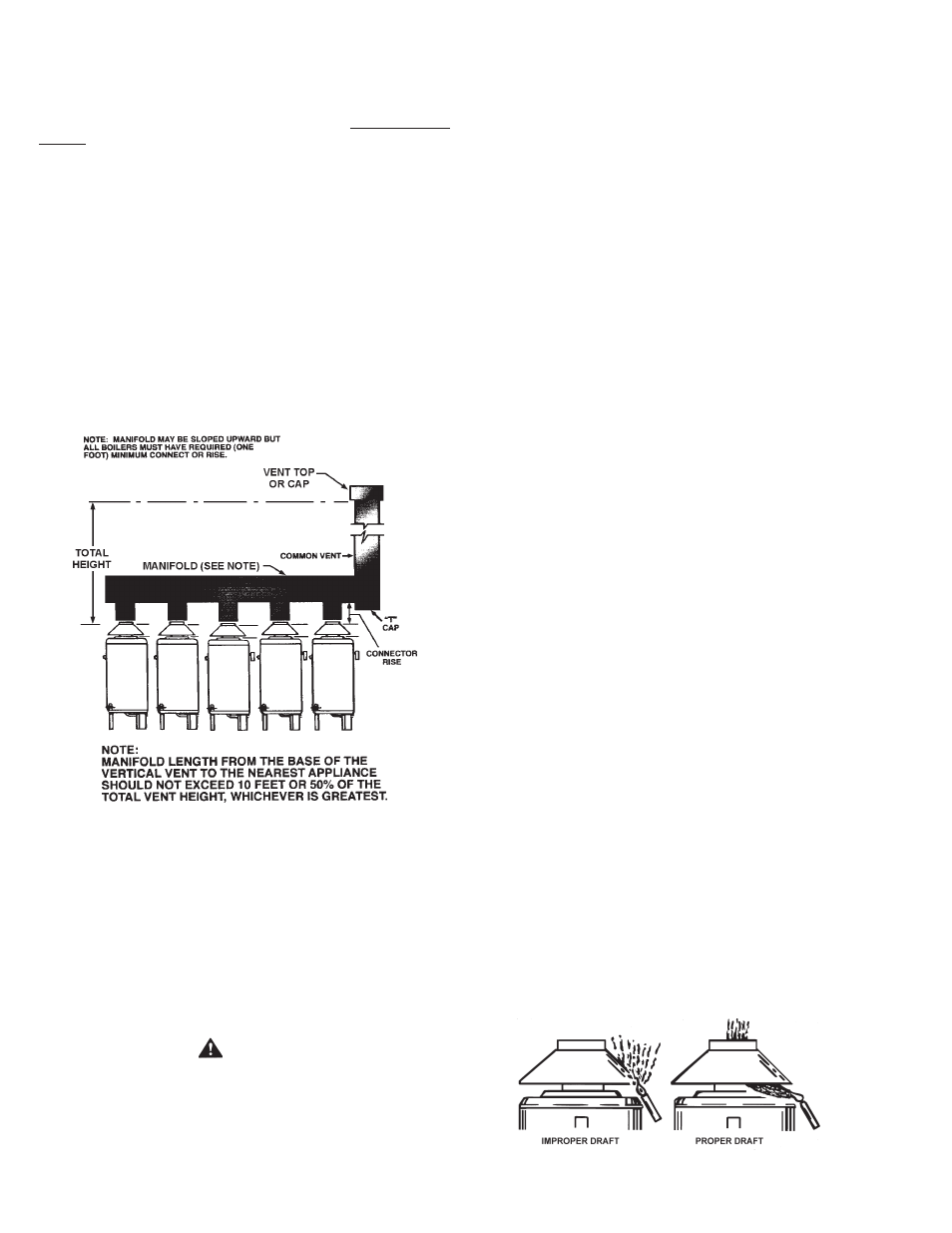

4. MULTIPLE VENT TABLE

Table 5 on page 17 has been compiled to show the material

sizes in a Type B doublewall combined vent system. Refer to

CAN/CSA B149 .1 (current edition), or the ASHRAE 1983 Equipment

Volume for further information.

A combined vent system is one in which two or more boilers at one

level are attached to a common vent.

In order to use table 5, the connector rise and total vent height must

be known. Connector rise is vertical distance from the draft hood outlet

to the point where the manifold connection is made. Total vent height

is the least vertical distance from a draft hood outlet to the top of the

vent. Local codes or utility requirements often govern termination

height. ULC listed doublewall gas vents, up through 24" (610mm)

diameter, can be installed in heated and unheated areas and can

pass through floors, ceilings, partitions, walls and roofs, provided

the required one inch clearance is observed. These vents should be

installed in accordance with CAN/CSA B149.1 (current edition).

EXAMPLE SHOWING USE OF THE HW-610 COMBINED VENT

SIZING TABLE

FIGURE 9.

VENTING MAINTENANCE - STANDARD VENTING

It is recommended that the heating surfaces and vent piping of

the appliance be checked every six months for dust, deterioration

and carbon deposits. Remove all soot or other obstructions from

chimney and flue which will retard free draft. Replace any damaged

or deteriorated parts of the venting system.

Qualified servicers should follow this procedure when the boiler’s

external heating surfaces and vent pipe need cleaning.

CAUTION

DO NOT USE A NYLON BRUSH OR OTHER STATIC CREATING

MATERIAL TO CLEAN DUST AND CARBON DEPOSITS FROM

HEATING SURFACES AND VENT.

SUCH DEPOSITS ARE FLAMMABLE AND MAY BE IGNITED BY

STATIC ELECTRICITY. USE A METAL BRUSH TO MINIMIZE THE

DANGER OF EXPLOSION.

1. Turn off the electrical power (main manual gas shutoff and pilot

valves, if applicable).

Allow boiler parts and vent to cool before disassembly.

2. Remove the boiler draft diverter and vent pipe running to the chimney.

• Check parts and chimney for obstructions and clean as necessary.

3. Remove burner from boiler and other metal parts as required to

clean and vacuum the heat exchanger and combustion coils.

• Refer to parts list supplied with this manual for disassembly aid.

4. Reinstall the parts removed in steps 2 and 3.

• Be sure the vent pipe has a minimum upward pitch of one quarter

inch per foot of length (21mm/m) and is sealed as necessary.

5. Restore electrical power and gas supply to boiler.

• Place boiler in operation by following the lighting instructions

in this manual.

• Check for gas leaks and proper boiler and vent operation.

VENTING - SIDEWALL (OPTIONAL) POWER VENT SYSTEM

If you are installing the optional Power Vent Kit, refer to your

HW Power Vent Kit Installation Instructions for proper wiring

and installation procedures. Contact your local A. O. Smith

representative for details.

VENTING SYSTEM

HAVE VENTING SYSTEM CHECKED EVERY SIX MONTHS FOR

OBSTRUCTIONS AND/OR DETERIORATION IN VENT PIPING.

A. Insofar as is practical, close all doors, windows and air inlets to

the building. Turn on all exhaust fans (range hood, bathroom

exhaust, etc.) so they will operate at their maximum speed.

Close fireplace dampers.

B. After allowing appliance to operate for five minutes, test for

spillage at the draft hood relief opening.

C. “CHECKING THE DRAFT. Operate vent connected gas utilization

equipment for several minutes and check to see that the combustion

products are going up the chimney or gas vent properly by passing

a lighted match or taper around the edge of the relief opening of

the draft hood. If the chimney or gas vent is drawing properly, the

match flame will be drawn into the draft hood. If not, the combustion

products will tend to extinguish this flame. IF THE COMBUSTION

PRODUCTS ARE ESCAPING FROM THE RELIEF OPENING OF

THE DRAFT HOOD, DO NOT OPERATE THE EQUIPMENT UNTIL

PROPER ADJUSTMENT OR REPAIRS ARE MADE TO PROVIDE

ADEQUATE DRAFT THROUGH THE CHIMNEY OR GAS VENT.”

D. Next, turn on all other fuel burning appliances within the same

room so they will operate at their full input.

Repeat step C above, checking the draft on each appliance.

FIGURE 10.