7 tunnel ventilation – Hired-Hand Evolution Series 3000/3001 User Manual

Page 33

Part No. 4801-5307 Rev 2-10

Evolution 3000 and 3001

33 of 70

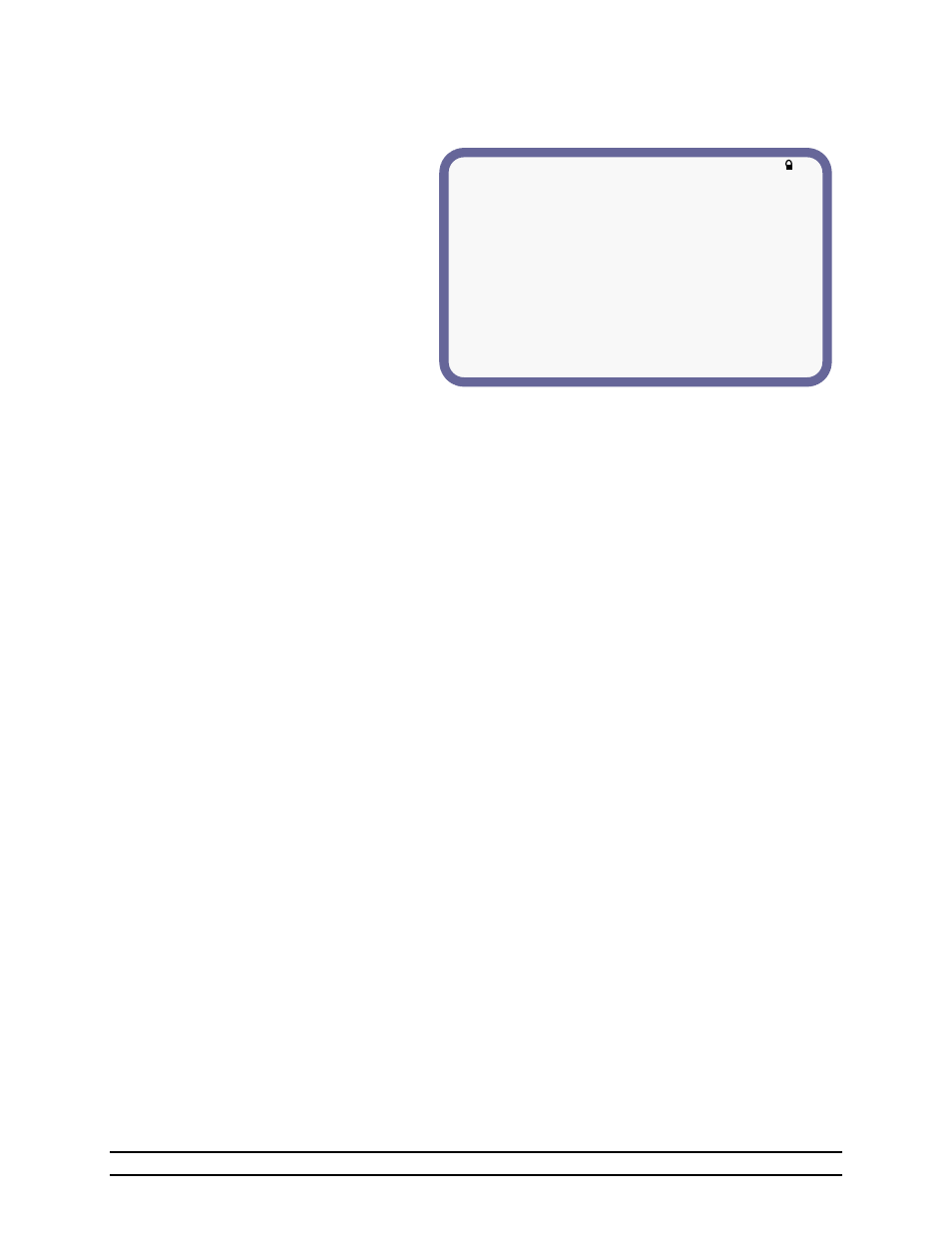

**TUNNEL SETUP**((1)Target = 75°)

(2)Tunnel Enabled = ON

Tunnel

(3)Sensors

Temperature

On

(4)---54321

(5)85.0°

Off (6)-----3-1

(7)80.0°

(8)Use Tunnel Target Pressure = No

(9)Natural Unit #2 is Tunnel Inlet = No

(10)Enable Low Pressure Alarm in Tunnel = Yes

(11)Increase High Temp Limit +2.0 in Tunnel

(12)Tunnel Timeout = 30:00 (30:00 max)

7.7 Tunnel

Ventilation

The Tunnel Setup screen sets the parameters necessary to operate in the Tunnel mode.

(1) Target – Displays the target temperature

of the building.

(2) Tunnel Enabled – Select either

Yes or No to enable or

disable going into the Tunnel

mode.

(3) Sensors – The user is given the

choice as to what sensors will

be used to enter and exit

Tunnel Mode; select any or all

of the available sensors. To

use the outside sensor when

entering tunnel set the sensors

to display the word “outside”

by turning all the sensors off.

(4) Tunnel ‘On Sensors’ – Selectable for 1-8 sensors. Select the sensors used for entering Tunnel Mode.

(5) Tunnel ‘On Temperature’ – The temperature at which the controller will go into tunnel mode.

(6) Tunnel ‘Off Sensors’ – Selectable for 1-8 sensors. Select the sensors used for exiting Tunnel Mode.

(7) Tunnel ‘Off Temperature’ - The temperature at which the controller will go out of tunnel mode.

(8) Use Tunnel Target Pressure – Yes or No. This will allow a different Target Pressure to be used in the

Tunnel mode.

(9) Natural Unit #2 is Tunnel Inlet – Yes or No. This indicates that PowerTrak Number 2 of the Natural

Set is a Tunnel inlet and will open during Tunnel.

(10) Enable Low Pressure Alarm in Tunnel – Yes or No. Set to Yes if it is desired to use a low pressure

alarm while in the tunnel mode.

(11) Increase High Temperature Limit +##° in Tunnel –While in the tunnel mode the Evolution 3000

can adjust the High Temperature Limit. Enter the number of degrees that the limit is to be

increased while in the tunnel mode. This increase will only be used while in tunnel.

(12) Tunnel Timeout – This feature prevents the controller from flip-flopping in and out of tunnel and

also provides a means for the controller to retry tunnel ventilation after a tunnel error. The Tunnel

Timeout counter forces the controller to wait at least 30 minutes between tunnel initiation. For

example, if the controller is in tunnel and an error occurs, the controller will reload the tunnel

timeout, exit tunnel ventilation, and sound the alarm. After the tunnel timeout expires, the

controller will reset the tunnel error, turn off the alarm, and if the conditions allow, retry tunnel

ventilation. The tunnel timeout will be reset during a power-on reset or if the Tunnel Enable is

toggled from off to on. As long as “30:00” is displayed, tunnel ventilation is allowed. If it is in

process of counting, then it is not allowing tunnel ventilation at this time due to a previous error or

because it has recently made an attempt.