Yokogawa DA100 User Manual

Page 69

IM DA100-01E

3-10

Temperature Measurement Using TC

DC voltage input for DC voltage measurement substitutes for this.

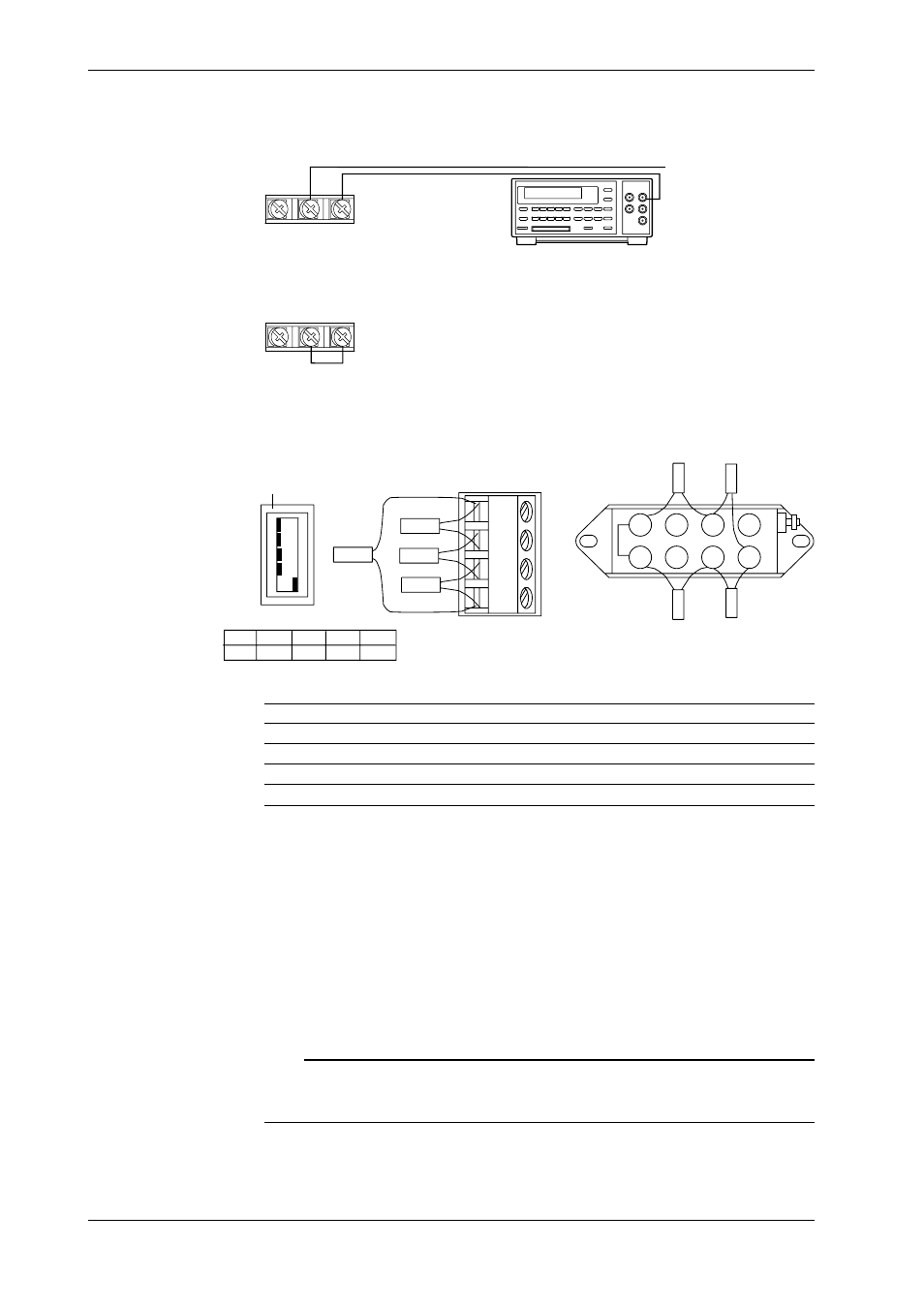

DC Current measurement

Apply the 20mA to channel 3

+

–

Input terminal

(CH3)

DC Current Generator

Short circuit between “+” and “–” terminal in channel 2

+

–

Input terminal

(CH2)

Strain measurement

Wire the strain gauge or the bridge box to the channel 2.

Jumper setting switch

ON

OFF

No.1

No.2

No.3

No.4

No.5

A(+)

B(L)

C(-V)

D(H)

DU500-12/DU500-13

DU500-14

No.1

OFF

No.2

OFF

No.3

OFF

No.4

OFF

No.5

ON

1

2

3

4

5

6

7

8

R4

R2

R3

R1

R2

R4

R3

R1

To R1 to R4, connect resisters with the specifications described below.

Calibration

Resisters R1, R2, R3

Resister 4

Accuracy

ZERO

120.000

120.000

±0.005%, ±0.3ppm/°C

2k SPAN

120.000

119.521

±0.005%, ±0.3ppm/°C

20k SPAN

120.000

115.294

±0.005%, ±0.3ppm/°C

200k SPAN

120.000

80.000

±0.005%, ±0.3ppm/°C

Voltage or Current Output Using Retransmission Module

When clibrating the retransmission module by confirming the output value, connect a DMM (a

product corresponding to HP3458A) to the terminal to be calibrated.

Calibration Procedure

1 Connect the equipment as described above.

2 Verify that the calibration conditions are satisfied.

3 Start the DAQ Software 32.

4 Start the calibration program by clicking the [Calibration] icon.

5 Carry out the calibration operations (A/D adjustment) conform the DAQ Software 32 User’s

Manual (IMDP12013-62E).

Note

Instead of operating the DAQ Software 32, calibration can also be carried out by communication interface

using the [XZ] command. For details concerning this command, refer to the User’s Manual “Data

Acquisition Unit Communication Interface”, IMDA100-11E.

3.4 About Maintenance and Calibration