4 about maintenance and calibration, About maintenance and calibration -9 – Yokogawa DA100 User Manual

Page 68

IM DA100-01E

3-9

3

Trouble-shooting and Maintenance

3.4

About Maintenance and Calibration

Since the DA100 Acquisition Unit (hereafter referred to as DA100) has no parts which are subject

to wear, periodical replacement of parts is not necessary. However, we recommend to inspect the

operation conditions periodically.

About Fuse Replacement

Although the DA100 is equipped with a built-in fuse, replacement of a blown fuse may not be

carried out by the customer himself. For replacement of the fuse, contact your nearest sales

representative. Addresses may be found on the back cover of this manual.

About Calibration

We recommend to calibrate the DA100, as described below, at least once a year to assure the

measurement accuracy.

Required Equipment

Name

Measurement

Accuracy

Recommended

Range

DC Voltage Generator

0V to 50V

0.005% of setting + 1

µV Yokogawa 9000*, 4808

DMM

0V to 50V

0.005% of setting + 1

µV HP3458A

Decade Resistance Box

0.1

Ω to 1000 Ω 0.01%

Yokogawa 2793

DC Current Gemerator

0 mA to 20 mA

0.05% of setting

Yokogawa 7651

* For 0V input, it is necessary to either short the input terminals, or to monitor the output voltage using the

DMM.

Calibrating Conditions

Ambient temperature

: 23

°C ±2°C

Ambient humidity

: 55

±10%RH

AC power supply voltage

: 100 to 240 VAC (AC power supply model)

DC power supply voltage

: 12 to 28 VDC (DC power supply model)

Power supply frequency

: 50/60 Hz

±1% (AC power supply model)

Warm-up time

: at least 30 minutes for the DA100, and necessary warm-up time for

the used equipment

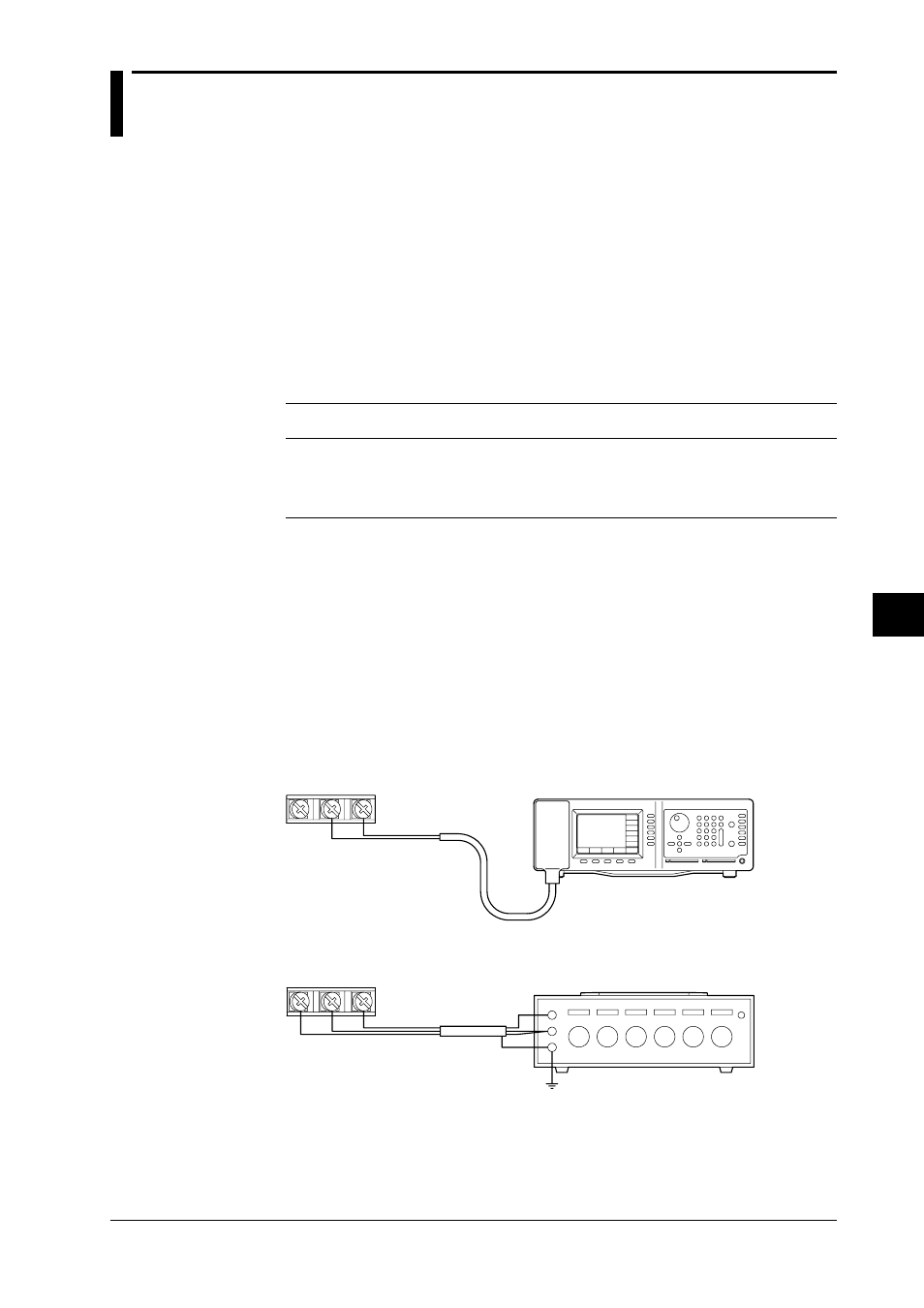

Connection

DC Voltage Measurement

+

-

DC Voltage Generator

Input terminal

Temperature Measurement Using RTD

B

b

A

Decade Resistance Box

Input terminal