Chapter 7, Auto-tuning (heat and/or cool) – Watlow Series 988LF User Manual

Page 47

Tuning, Manual Operation, Alarms, and Error Codes, Chapter 7

WATLOW Series 988LF Users Manual

7.1

Chapter 7 Tuning, Manual Operation,

Alarms and Error Codes

Auto-tuning (Heat and/or Cool)

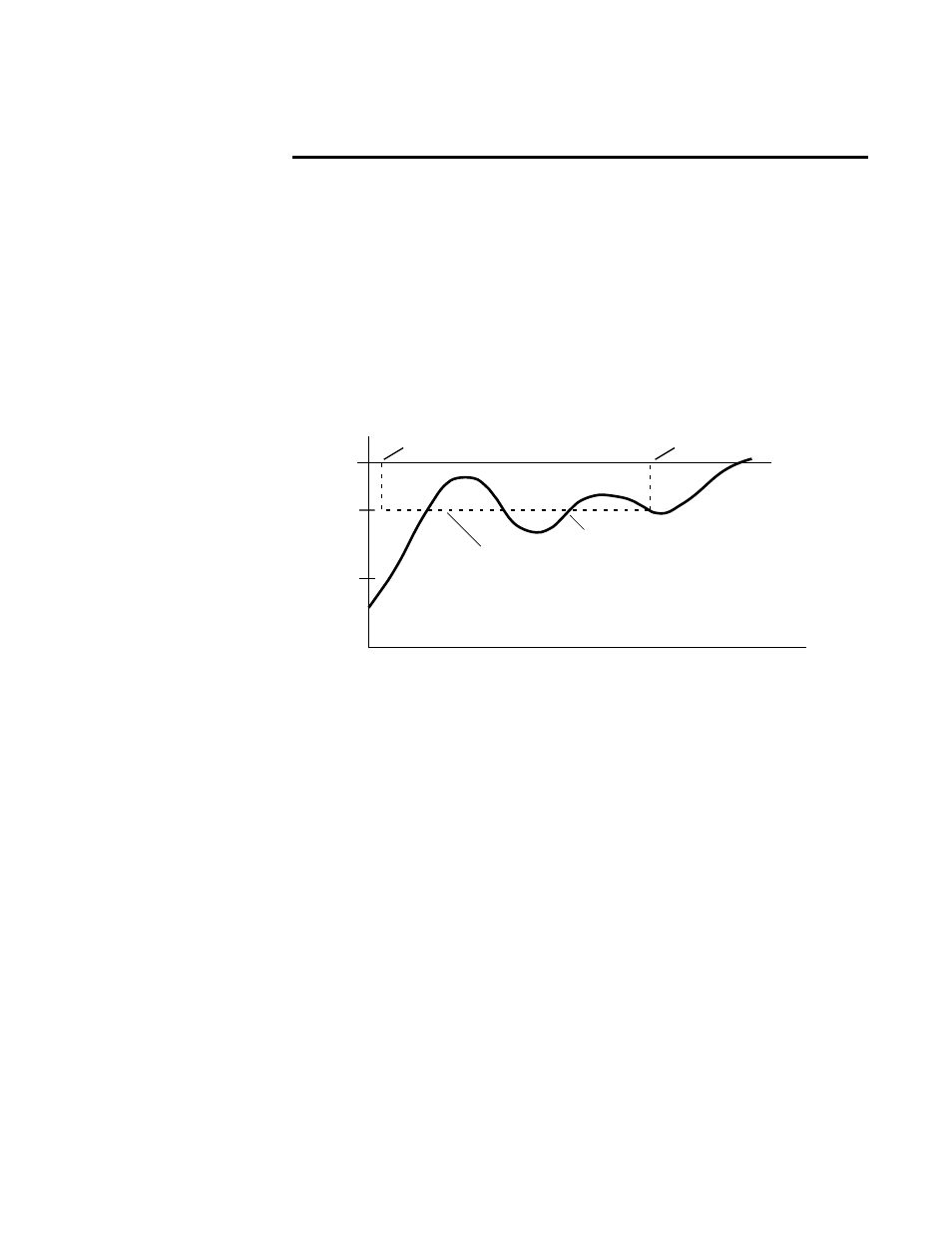

The Series 988LF can automatically tune the PID parameters to fit the

characteristics of your particular thermal system.

Once the auto-tune sequence has begun, all PID values for both heat and

cool are set to [```0] and the control goes into an on/off mode of control

at 90% of the established set point. The displayed set point remains

unchanged.

200

°

Temperature

set point

100

°

process

180

°

auto-tune

begins

auto-tune

complete

90% of

set point

Auto-tuning at a set point of 200

°

F

Time

When the control finishes “learning” the system, it resumes standard PID

control using the PID values established by the auto-tuning process.

Changing the set point during an auto-tune restarts the auto-tune

procedure.

During auto-tuning the process must cross the set point four times within

an 80-minute time span for the Series 988LF to successfully complete the

auto-tune. If this does not happen within the 80-minute time limit, the

Series 988LF chooses PID values based on the 80-minute tuning cycle

performed.

To start auto-tuning:

1. Press the Mode key µ to advance through the Operations menu

until the [`AUt] prompt appears in the lower display.

2. Use the Up-arrow > or Down-arrow < key to select [``On] or

[`OFF].

3. Press the Display key ¥. While the control is in the tuning mode

the lower display alternates every second between the normal

information and the [tunE] prompt.

NOTE:

A useful reference on

tuning is Tuning of

Industrial Control

Systems by Armando B.

Corripio, published by

the Instrument Society of

America

.

Figure 7.1 -

Auto-tuning example

ç

CAUTION:

If a mechanical relay or

contactor is switching

power to the load, a

longer cycle time may

be desirable to

minimize wear on the

mechanical

components. The

typical life of a

mechanical relay is

100,000 cycles. Verify

that the cycle time

selected is appropriate

for the output device

type. Failure to do so

could result in damage

to equipment and/or

property.