Input 2 wiring, Remote set point option wiring, Thermocouple or 0-50mv (high impedance) – Watlow Series 988LF User Manual

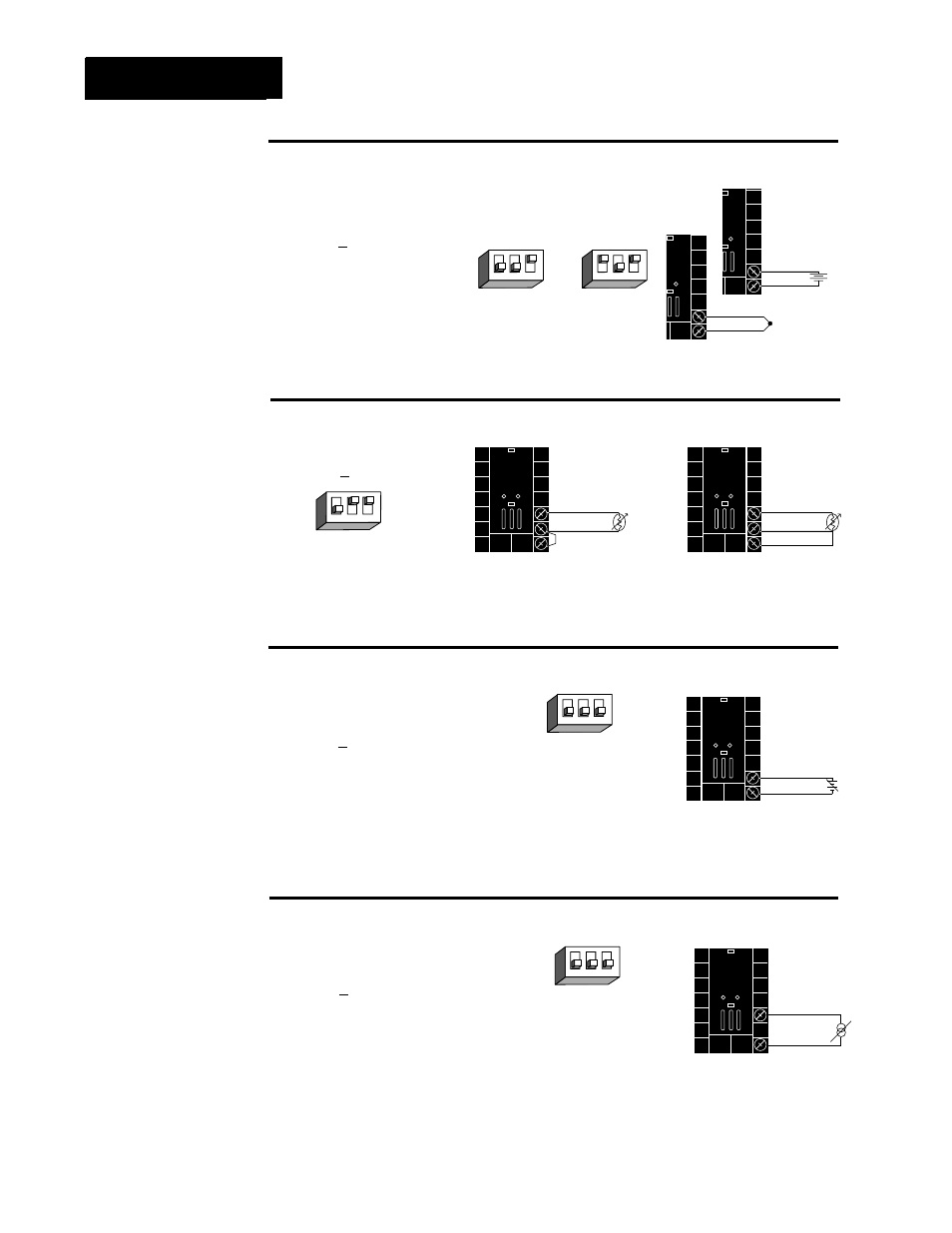

Page 18: Figure 2.8d, 98 _ l _ _ - a a _ _ remote set point option, Figure 2.8a

2.8

WATLOW Series 988LF User’s Manual

Installation and Wiring, Chapter 2

Figure 2.8d —

0-20mA or 4-20mA Process

Universal signal conditioner

98 _ L - _ 2 _ _ - A A _ _

Input impedance: 7

Ω

Remote Set Point Option

Figure 2.8c —

0-5V

О

О

, 1-5V

О

О

or 0-10V

О

О

(dc) Process

Universal signal conditioner

98 _ L - _ 2 _ _ - A A _ _

Input impedance: 10K

Ω

Remote Set Point Option

Figure 2.8b —

RTD (2 or 3 Wire) 100

Ω

Universal signal conditioner

98 _ L - _ 2 _ _ - A A _ _

Remote Set Point Option

20

19

-

+

Figure 2.8a —

Thermocouple or 0-50mV (high impedance)

Universal signal conditioner

98 _ L - _ 2 _ _ - A A _ _

Input impedance: 20M

Ω

Remote Set Point Option

19

20

+

-

Jumper

#19 to #20

for 2 wire

RTD

19

20

18

S2

S1

DIP Switch

Setting

R, S, B

DIP Settings

J, K, T, N, C, E, D, Pt2,

0-50mV DIP Settings

DIP Switch

Setting

19

20

18

S2

S1

S3

O

N

↑

1

2

3

O

N

↑

1

2

3

O

N

↑

1

2

3

O

N

↑

1

2

3

20

18

-

+

DIP Switch

Setting

O

N

↑

1

2

3

19

20

+

-

0-50mV

NOTE:

Successful installa-

tion requires five

steps:

• Model number and

software choice

(Appendix);

• DIP switch set-

tings (Chapter 1);

• Sensor match

(Chapter 2 and

Appendix);

• Sensor installation

(Chapter 2); and

• Wiring (Chapter 2).

Input 2 Wiring

ç

CAUTION:

An external resistor

is required for

0-20mA and 4-20mA

process wiring to

prevent a high in-

rush current which

could burn out the

controller’s 7-ohm

resistor. See page

2.4 for recommen-

dations.