Changing the position of a switch, Changing the position of a dip switch, Dip switch location and orientation – Watlow Series 920 Microprocessor-Based Ramping Control User Manual

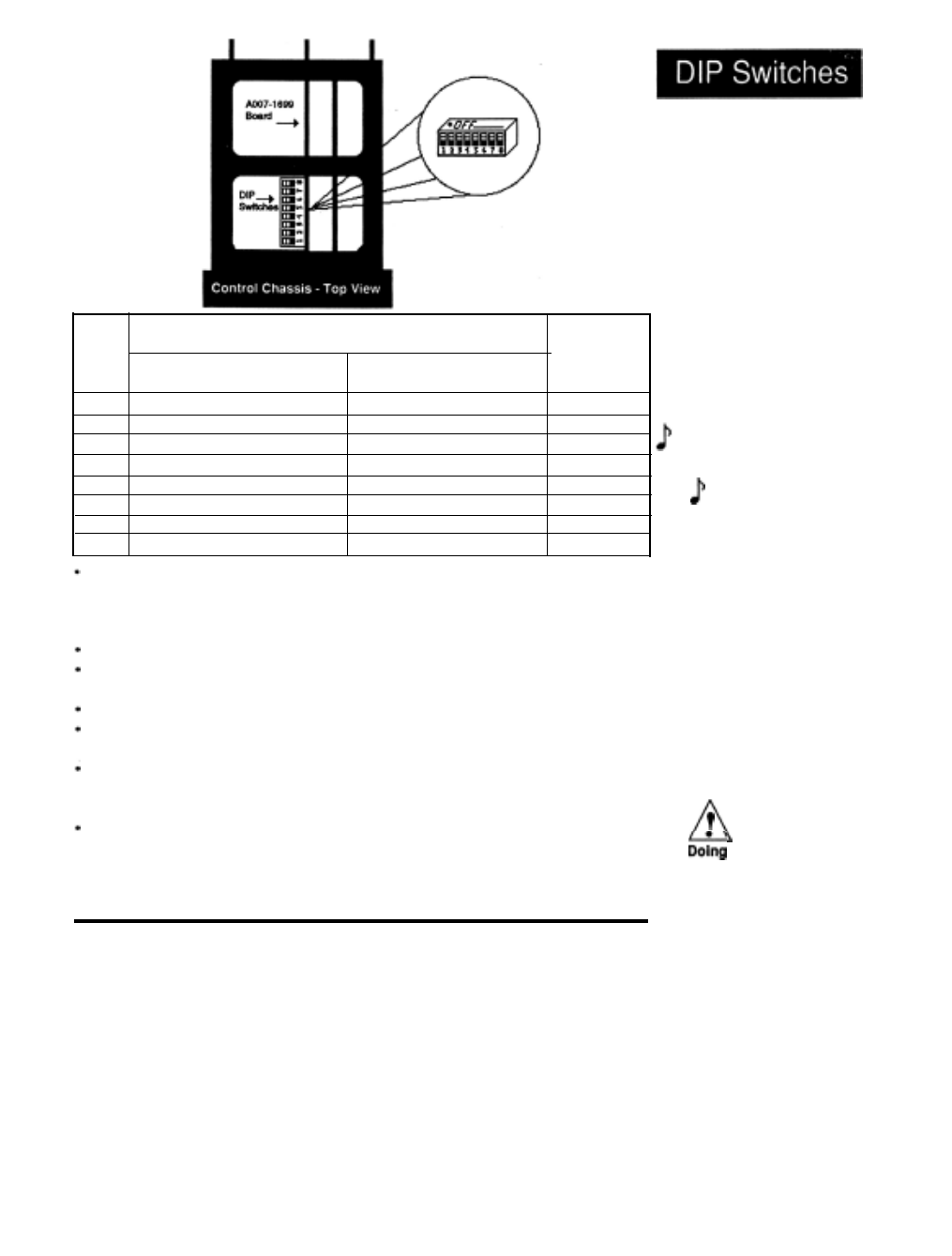

Page 9: Figure 3, 9 dip switch selection table 1

DIP

Function

Normal

Table 1 -

SW#

Operating

DIP Switch

ON

OFF

Position

Selection.

1

Cold Start

Warm Start OFF

2

Not Used

Not Used

OFF

3

Tenths of units displayed

No decimal displayed

Choose

4

0-5VDC/0-20mA input

l-5VDC/4-20mA input

Choose

5

Primary output is 4-20mA

Primary output is not 4-20 Model # Dep,

6

LEDs are load indicators

LEDs are ° F or ° C

Choose

7

Selected SPCLFUNC promts All SPCLFUNC prompts

Choose

8

Factory Test/Calibrate

Normal Operation

OFF

DIP switch #1 determines a warm or cold start. A

“warm”

start saves all pro-

grammed information in the 920s memory back-up protection. A “cold” start is a

“clean” startup condition; all user-programmed information is lost. The Series

920 leaves the factory programmed for a warm start.

DIP switch #2 is not used.

DIP switch #3 determines if the decimal point is displayed in tenths of units for

process inputs.

DIP switch #4 is for 0-5VDC/0-20mA input or l-5VDC/4-20mA input selection.

DIP switch #5 is for units with 4-20mA output. If your unit has 4-20mA output,

set switch # 5 ON for the Primary output.

DIP switch #6 determines the function of the front panel LEDs to the right of the

actual display. When ON, these LEDs can be used as a diagnostic tool for tuning

or system troubleshooting, see Page 12 and 33.

DIP switch #7 is OFF, all SPCLFUNC prompts are displayed, when ON, only

factory selected prompts appear. See Page 42. DIP switch #8 is a factory test/

calibrate switch.

Changing the Position of a Switch

Whenever you change the position of a DIP switch, follow this procedure:

1.

2.

3.

4.

5.

Remove power from the 920. Turn the front panel screw 90°counterclockwise.

Grip the front panel bezel and pull it straight out from the control case.

The control chassis will come out of the case as you pull the bezel.

Set the DIP switch to the position you want.

Return the control chassis to the case. Be sure you have it oriented cor-

rectly. It will not fit in upside down, but check just the same. Press

firmly, but gently, to seat the chassis.

Secure the front panel screw and re-apply power to the 920.

Figure 3 -

DIP Switch Location

and Orientation.

NOTE:

For units with

process input only.

If your unit does not

have process input,

DIP Switch #3

should be in the OFF

position.

WARNING:

a cold start

will cause all setup

parameters and files

to be lost. DO NOT

put DIP switch #1 in

the ON position

unless all user-

programmed

information is to be

cleared.

Starting

Out,

Chapter

1

WATLOW Series 920

User’s Manual

9