Process field calibration procedure, Figure 39, Equipment required – Watlow Series 920 Microprocessor-Based Ramping Control User Manual

Page 66: Set-up and calibration

Process Field Calibration Procedure

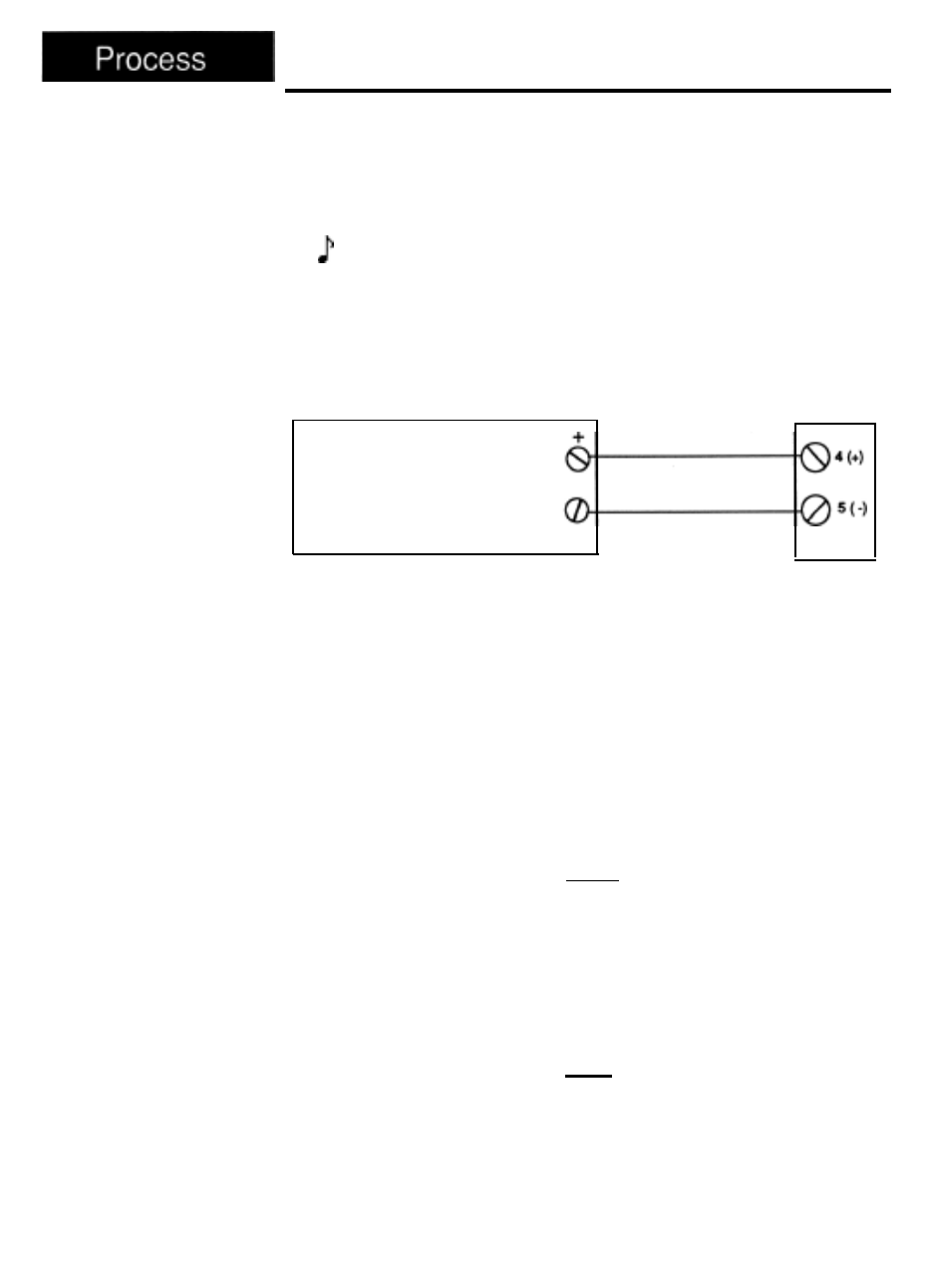

Figure 39 -

Voltage/Current

Source to

Series 920

Connection

Diagram

Equipment Required

l

4-1/2 digit, digital voltmeter (DVM).

l

Precision voltage/current source.

Set-up and Calibration

NOTE:

Before calibration on an installed control, make sure all data and parame-

ters are documented.

1.

Connect the voltage/current source to #4 Positive and #5 Negative on the

Series 920 terminal strip. See the figure below.

Series 920

Terminal Strip

Voltage/Current

Source

2.

3.

4.

5.

6.

7.

8.

9.

,

.

Connect AC line voltage, L1 to #17, L2 to

#20,

ground to #21 on the Series

920 terminal strip.

Set DIP switch #8 ON. Apply power to the 920 and allow it to warm up for

15 minutes. The unit should be in the TEST mode.

Using the MODE key, advance until the IN X parameter appears on the

alphanumeric display. Using the UP/DOWN keys, advance to the correct

input type. Press the ENTER key.

Connect DVM common to TP84 and DVM positive to TP36 on the AOO7-

1703 circuit board. Located on the top side behind the center chassis

support. DVM should be set up for DC volts, and in a range capable of

displaying 32.00 ± 10mv.

Press the MODE key until HOF XX.XX appears on the alphanumeric dis-

play. (The decimal point will not appear on the display of your control.)

Use the UP/DOWN keys to adjust the alphanumeric display on the 920 to

match the reading on the DVM. Once the two readings match, press the

ENTER key.

Press the MODE key until MA2 XXXX appears. Input 0 volts for a 0-5 volt

input type, or 4mA for a 4-20mA input type. Press the ENTER key.

Allow

10 seconds for the unit to stabilize.

Press the MODE key until MAG XXXX appears. Inpuy 5 volts for a 0-5 volt

input type, or 20mA for a 4-20mA input type. Press the ENTER key. The

unit is now calibrated for process inputs. Allow 10 seconds to stabilize.

The process reading on the ACTUAL display should be sitting at the RAH

setting.

Remove power for the Series 920. Remove wires from #4 and #5. Set DIP

Switch #8 to the OFF position.

66

WATLOW Series 920 User’s Manual

Appendix