Warner Electric SFPBC-500, SFPBC-650 User Manual

Page 7

7

Warner Electric • 800-825-9050

P-202-01 • 819-0482

The illustration drawing, parts list, and exploded view

for this unit can be found on pages 32-33.

The SFC-500 clutch-couplings are bearing-mounted

units. Either the field-and-rotor assembly or the

ar ma ture-and-hub assembly can be installed first,

depending on the characteristics of each application.

A. Aligning the shafts

Before the clutch coupling can be installed, the

mount ing shafts of the motor and reducer or other

hardware must be aligned to each other. Follow the

instructions provided for the pin drive units on page 3.

B. Installing the Conduit Box

Installed the conduit box on the field assembly.

In struc tions for this procedure can be found on are

supplied with conduit box.

C. Mounting the Field-and-Rotor

Assembly

1.

Insert a key into the keyway in the bore of the

rotor, and slide the assembly onto the shaft.

2.

If the armature has been secured to the shaft

first, then adjust the rotor’s position to allow

ap prox i mate ly 1/32-inch between the two

faces. (Figure 3)

3.

Secure the assembly on the shaft by

alternately tight en ing the two setscrews.

4.

A tab or torque arm is provided to prevent the

field from rotating with the shaft. Insert either

a pin in the U-slot or a fork around the torque

arm to prevent this rotation. Under no

circumstances, however, should the field be

so tightly restrained that it preloads the bear-

ing. For more information on torque tabs, see

page 18.

SFC-500 Clutch Coupling Spline Drive

Armature

D. Assembling the Armature and Hub

The clutch-coupling units contain spline drive arma-

tures and hubs. The armatures are shipped with a

built-in autogap spring accessory. This device auto-

matically maintains a gap of about 1/32'' between the

armature and magnet faces for the life of the unit.

(Figure 3)

These units are shipped with the armature and

autogap already assembled. Follow these instructions

to as sem ble the splined armature assembly and hub:

Step 1

Place the splined hub on a flat surface. The

extended portion of the hub, where the set

screw holes are lo cat ed, should be down.

Step 2

Check the detent ring in the armature

assembly to make sure it is centered evenly

around the spline. This ring moves freely,

but it should be centered for easier as sem -

bly of the hub.

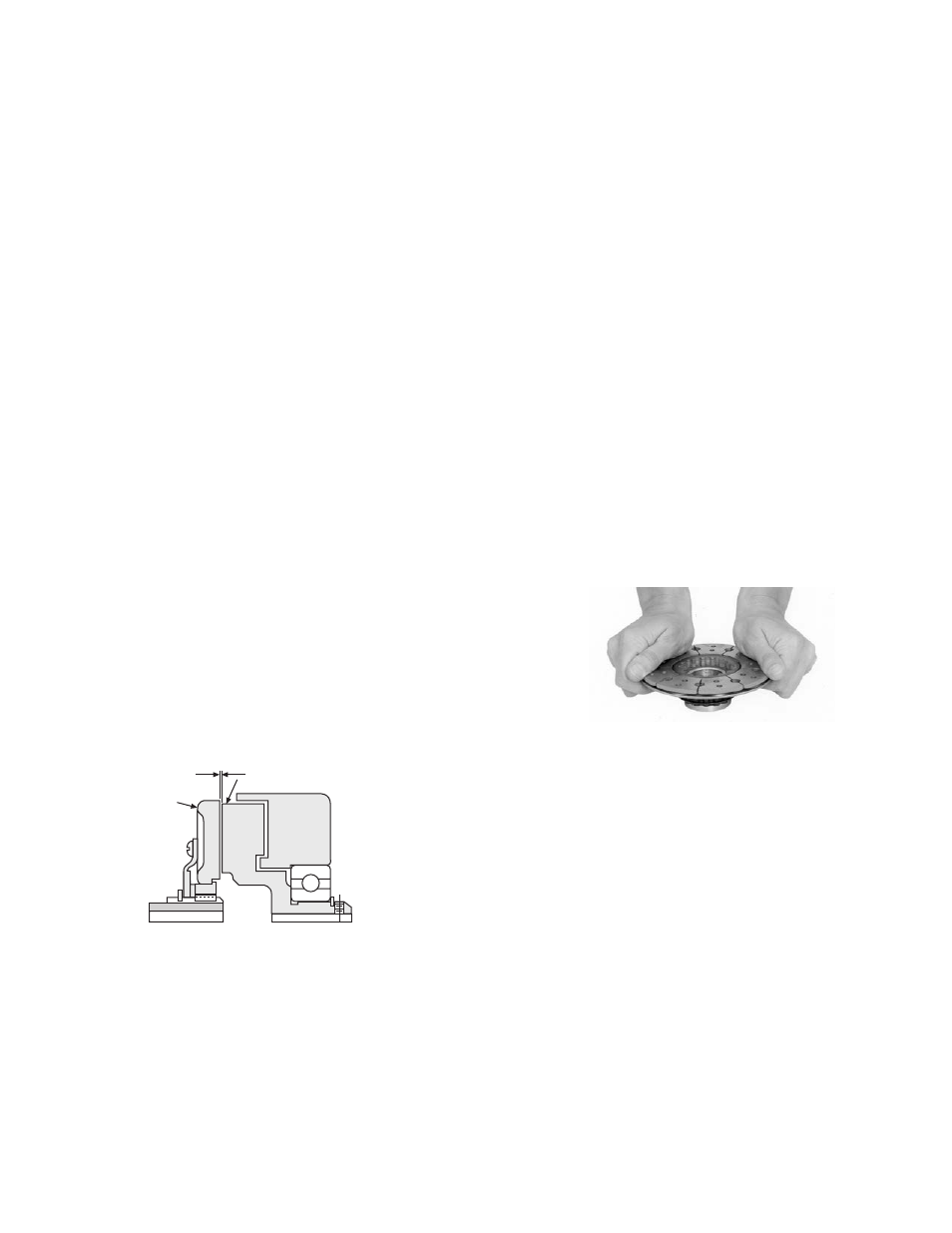

Step 3

Holding the armature with the segmented

side up, press the armature onto the splined

hub. This is most easily done by applying

firm back-and-forth pressure. (Figure 2)

Step 4

Push the assembly up against the retainer

ring.

E. Mounting the Armature-Hub Assembly

1.

Insert a key in the keyway of the hub and

slide the armature-hub assembly on to the

shaft.

2.

If the field-and-rotor assembly has been

se cured to the shaft first, then adjust the

armature’s position to allow a 1/32-

inch gap between the two faces. (Fig ure 3)

3.

Secure the armature-hub assembly in this

po si tion by tightening the two setscrews in

the hub.

4.

Check the assembly by pressing the armature

into contact with the rotor face and then

releasing it. The armature should spring back

about 1/32''. This gap will be automatically

maintained for the life of the unit.

Figure 2

1/32 inch Gap

Rotor

Armature

Figure 3