Warner Electric SFPBC-500, SFPBC-650 User Manual

Page 18

18

Warner Electric • 800-825-9050

P-202-01 • 819-0482

Torque Tabs

Clutches

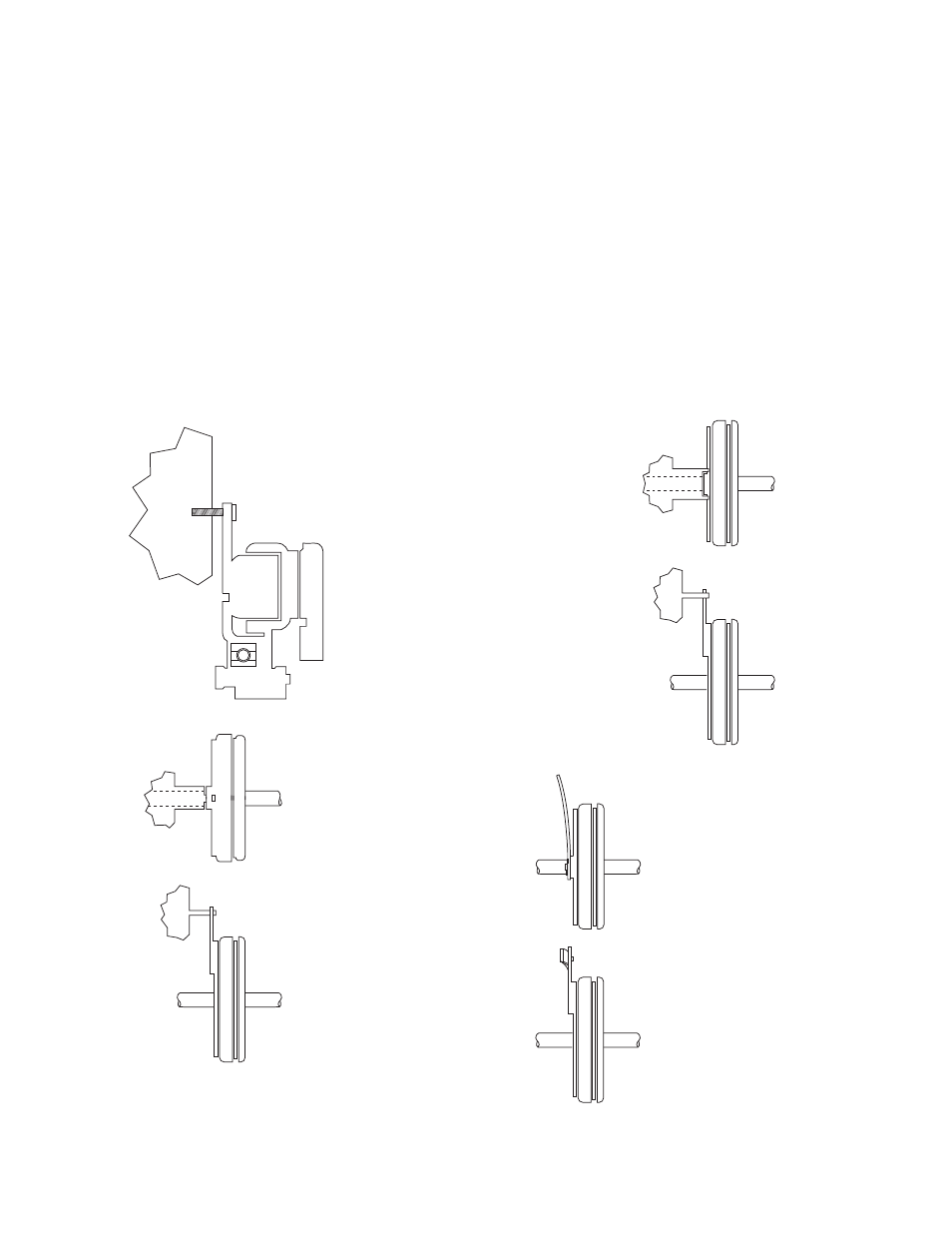

Many Warner Electric clutch assemblies have a bearing

mounted stationary field. By design the bearing main -

tains its proper position between the field and rotor

mak ing it easy for the customer to mount the field-rotor

as sem bly. However, the bearing has a slight drag which

tends to make the field rotate with the rotor if not re -

strained. And, since the field has lead wires attached, it

must be restrained to prevent rotation and pulling of

these wires. To counteract this rotational force, the field

has a “torque tab” to which the customer must attach

an ap pro pri ate anti-rotational restraint.

A few hints regarding proper torque tab restraints are in

order. First and foremost, it is important to recognize that

the force to be overcome is very small and the tab

should not be restrained in any manner which will pre-

load the bearing. For example, if the clutch is mounted

with the back of the field adjacent to a rigid machine

member the customer should not attach a capscrew

tightly between the tab and the machine member. This

may pull the tab back against the rigid member as shown

in Figure 1 and preload the bearing. The recommended

methods are il lus trat ed in Figures 2, 3, and 4. The

method selected is primarily a matter of customer prefer-

ence or con ve nience.

Figure 1

Rigid Member

Figure 3

Pin in Hole

Loosely

Figure 2

Rigid Member

Straddling Tab

Figure 4

Flexible Strap