Warner Electric SFPBC-500, SFPBC-650 User Manual

Page 4

3.

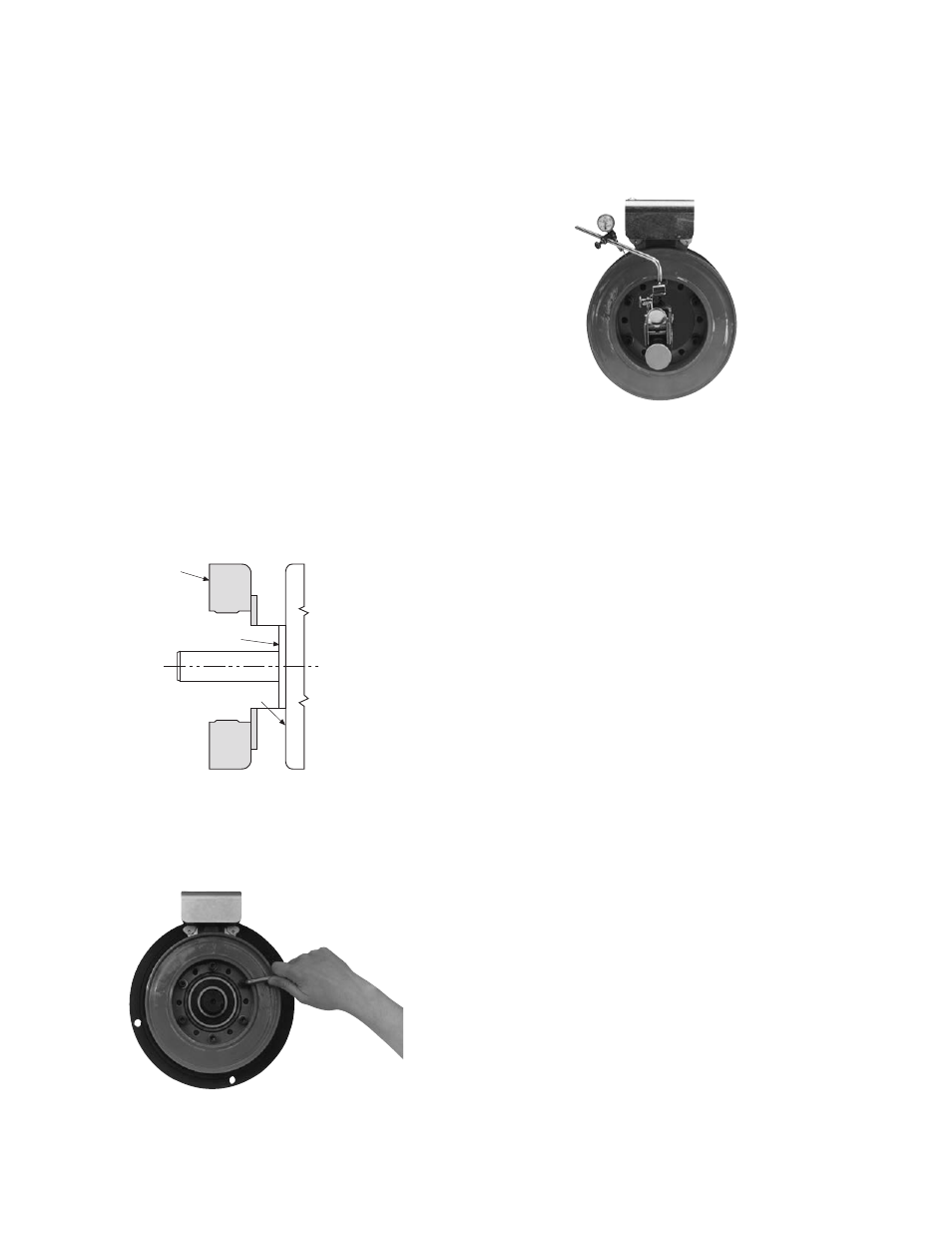

The field assembly is then fastened in place

with capscrews and lockwashers. (Figure 3)

4.

Once the unit is in place, it must be square

and con cen tric with the shaft in accordance

with the tol er anc es listed on the drawings.

(Figure 4)

5.

The rotor is mounted on the shaft with a

taperlock bushing. Insert the bushing

into the tapered bore.

6.

Loosely assemble the two locking screws

between the bushing and the rotor.

7.

Insert the key into the shaft keyway, and slide

the rotor assembly over the key and on to the

shaft.

8.

Adjust the rotor’s position to achieve the over-

all axial dimension “L” (page 34) when the

bushing is se cured.

9.

Secure the assembly in this position by

alternately tightening the two locking screws.

4

Warner Electric • 800-825-9050

P-202-01 • 819-0482

Flange-Mounted Units

The fields and rotors are shipped separately for

flange mounted units. On some applications it will be

nec es sary to mount the rotor first, and then bring the

field into position. In other instances the field will be

mounted first, and then the rotor (mounted on a shaft)

will be inserted into place.

In either case, the rotor and field must be

positioned in accordance with the overall axial

dimension from the face of the rotor to the back of

the field flange as shown on the illustration drawings

(dimension “L,” page 34). Hold ing this dimension will

assure the proper axial clearance between the field

and the rotor.

1.

Care must be taken in selecting the location

for mount ing the field assembly. Pilot diame-

ters are ma chined on the field mounting flange

to aid in holding the field in the proper posi-

tion.

2.

An appropriate pilot diameter must be

provided on the mounting surface as well.

(Figure 2)

Field

Pilot Diameter

Mounting Surface

Figure 2

Figure 3

Figure 4