Warner Electric Recommended Electrical Installation Procedure for Warner Electric Clutches and Brakes User Manual

Installation instructions, At 25, At 55

Recommended Electrical Installation Procedure

for Warner Electric Clutches and Brakes

Installation Instructions

P-1390

819-0188

Warner Electric clutches and brakes conform to UL

(Underwriters Laboratories) and CSA (Canadian Standards

Association) requirements. All packaged products come with

conduit boxes or are enclosed in housings with

provision for electrical conduit connection. UL Listed/CSA

Certified fittings must be used in making connections. All SF

clutch fields and brake magnets, in size 400 and larger,

accept UL and CSA conforming conduit boxes available from

Warner Electric. UL Listed/CSA Certified fittings must be

used in making connections.

The National Electrical Code (NEC) requires conductors sub-

ject to physical damage be adequately protected. When

electrical conduit is used, a minimum of 12" of 1/2" flexible

conduit is to be used between each brake and/or clutch and

its box. This construction will prevent improper bearing load-

ing in bearing mounted units and ease field and magnet

assembly and disassembly. Refer to the information below for

proper installation practices and

wire sizes.

Notwithstanding the above recommendations, all

electrical installations should conform to NEC and/or

other governing electrical codes.

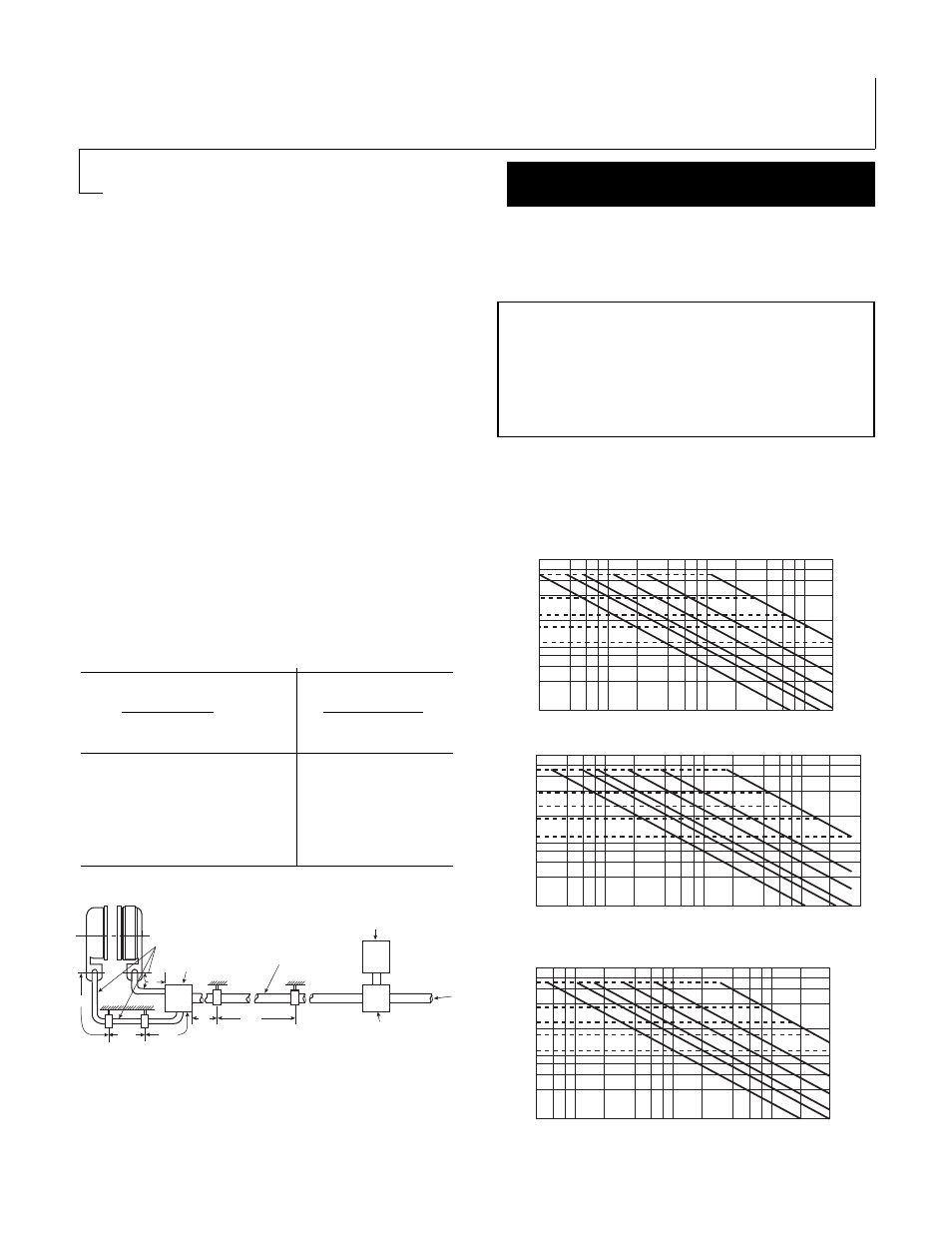

Recommended wire size versus maximum distance.

Fractional Horsepower

Integral Horsepower

Sizes 170-400

Sizes 500-1525

Wire Size

Distance (feet)

Distance (feet)

AWG

6 volt

24 volt 90 volt

6 volt

24 volt 90 volt

18

20

280

1000

4

65

700

16

30

430

6

95

14

50

720

10

160

12

75

720

10

160

10

125

25

400

8

200

40

1/2" Flexible Conduit

12" Min. - 6' Max.

4" x 4"

Junction Box

Power

Supply

115 VAC

Incoming

Line

Power

4" x 4"

Junction

10'

Max.

3'

Max.

12"

Max.

4'-6'

Max.

12"

12"

3/4" Rigid Conduit

General construction wire type MTW or THW recommended.

#6 terminal screws (size 400 and smaller) torque to 15 in-lb.

#8 terminal screws (size 500 and larger ) torque to 20 in-lb.

Cycle Rates

The performance curves on this page and the following

page meet current UL Listing and Recognition coil

temperature limitations, which are class A or 105° C.

Consult Warner Electric's Catalog, P-1234 or P-1264,

for performance characteristics for applications not

subject to UL listings.

AT Models

Select the chart for the appropriate size AT clutch or brake. The

intersection of the reflected inertia (lb. ft.) and speed difference

(RPM) lines will indicate the maximum cycle rate for that size

unit.

Inertia (lb ft

2

)

S

p

e

e

d

D

if

fe

re

n

c

e

(

R

P

M

)

AT 25

.1

.2

.3

.5

1

2

3 4 5

10

20 30

50

100

100

600

900

1200

1800

3600

60 C

PM

60 CPM

20 C

PM

20 CPM 10 C

PM

10 CPM

5 C

PM

5 CPM

1 C

PM

1 CPM

30 C

PM

30 CPM

60 C

PM

20 C

PM

10 C

PM

5 C

PM

1 C

PM

30 C

PM

.4

40

Inertia (lb ft

2

)

S

p

e

e

d

D

if

fe

re

n

c

e

(

R

P

M

)

AT 55

.1

.2

.3

.5

1

2

3 4 5

10

20 30

50

100

300

100

600

900

1200

1800

3600

60 C

PM

60 CPM

30 C

PM

30 CPM

20 C

PM

20 CPM

10 C

PM

10 CPM

5 C

PM

5 CPM

1 C

PM

1 CPM

60 C

PM

30 C

PM

20 C

PM

10 C

PM

5 C

PM

1 C

PM

.4

40

Inertia (lb ft

2

)

S

p

e

e

d

D

if

fe

re

n

c

e

(

R

P

M

)

AT 115

.2

.4

1

2

4

3

5

10

20 30

50

100

300

100

600

900

1200

1800

3600

60 C

PM

60 CPM

30 C

PM

30 CPM

20 C

PM

20 CPM

10 C

PM

10 CPM

5 C

PM

5 CPM

1 C

PM

1 CPM

60 C

PM

30 C

PM

20 C

PM

10 C

PM

5 C

PM

1 C

PM

.3

.3

40

.5

Warner Electric

•

800-825-9050

P-1390

•

819-0188