Warner Electric SFPBC-500, SFPBC-650 User Manual

Page 20

20

Warner Electric • 800-825-9050

P-202-01 • 819-0482

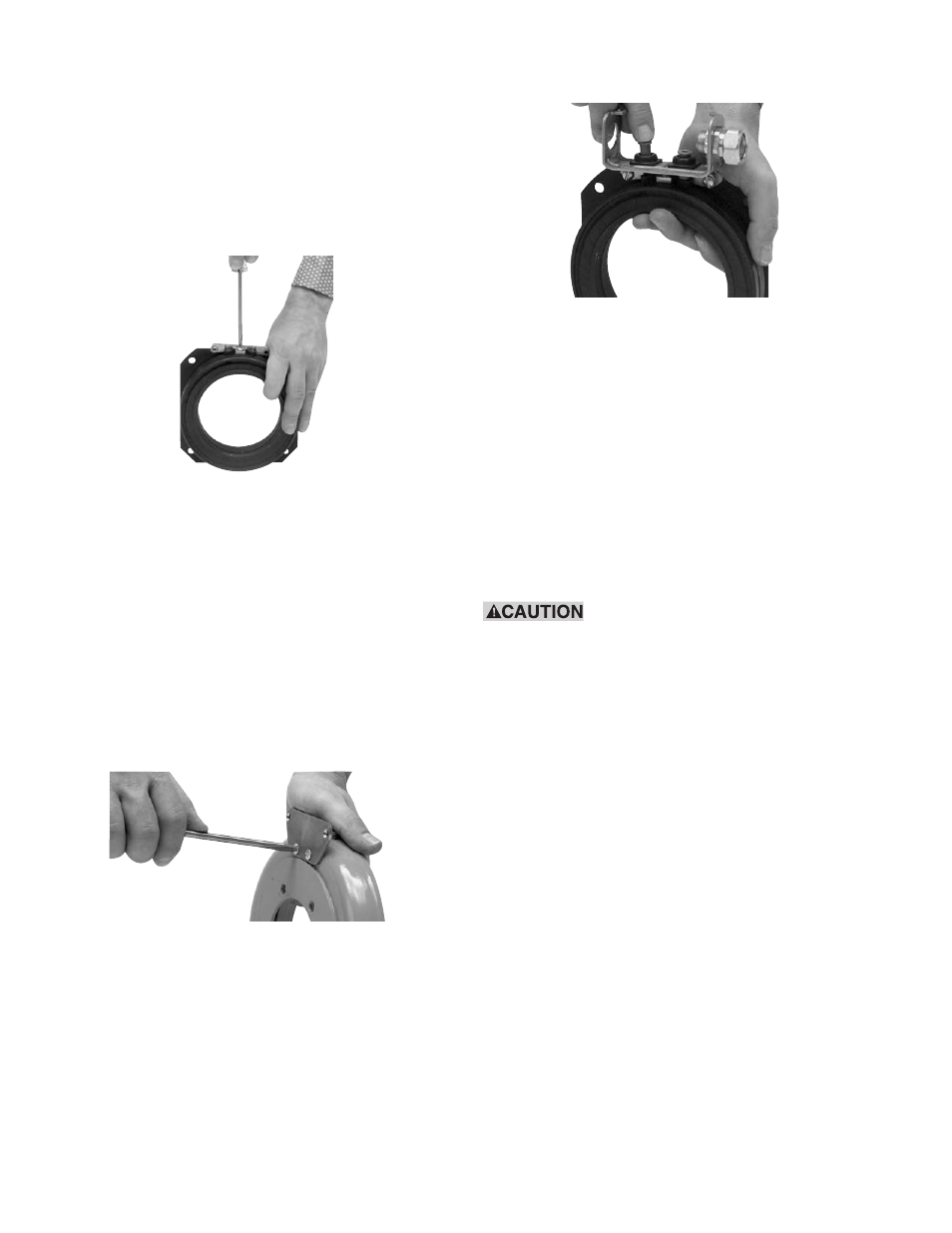

Step 1

Fasten bracket (1) to the clutch or brake

with one No. 10-32 hex. washer head screw

and washer (2). The square projection on

the clutch or brake between the terminals is

to

be assembled into the square hole in

the

bracket. The bracket flange is

installed

toward the back of the unit.

(See Figure 1)

Step 2

Assemble a 1/2" flexible conduit fitting into

the desired end of the conduit box (3). If the

grounding nut on this conduit fitting is

tightened after the conduit box is in -

stalled on the magnet or field, avoid using

excessive tap ping force, which could dam-

age the mounting. (Step 6)

Step 3

Mount conduit box (3) to the bracket (1).

The con duit box flange must be toward the

back of the clutch or brake. Secure the box

with two No.10-32 hex. washer head screws

(4). (See Figure 2)

Step 4

Snap the two rubber grommets (6) into two

square holes in the bottom of the conduit

box. The grom met crowns should be in the

box and the rubber flanges should be on

both sides of the metal floor. (See Figure 3)

Figure 1

Figure 2

Rigid conduit must not be con nect ed

directly to the box. A minimum of 12" of flexible

cable must be used. It is recommended that

flexible "UL" listed liquid-tight, me tal lic or

non-metallic conduit, meet ing local codes, be used

with appropriate fit tings. Flexible cable is required

to prevent side loading of bearing on bear ing

mounted clutches and brakes and possible

de for ma tion of the conduit box or com po nents

during assembly.

Step 7

Press protective plug (5) into the unused

conduit hole in the box.

Step 8

Slide one rubber cap (8) onto each of the

two supply conductors, small end first.

Connect the two supply con duc tors (with

rubber caps) to the magnet or field ter mi nals

using two No. 6 or No. 8 screws (11). Use

wire re tain ing ring terminals supplied with

the clutch or brake terminal accessory. The

stripped wires may be wrapped around the

screw between the wire terminal ring and

the screw head or other ring type terminals

such as "AMP" may be used. The screws

are then assembled through the terminal

spacers (7) and threaded into the clutch or

brake terminals.

Step 5

Push two terminal spacers (7) through the

grom mets with the spacer flanged ends

inside the conduit box. (See Figure 3)

Step 6

Connect electric supply cable to the fitting

installed on the conduit box. Use D.C.

supply only.

Figure 3