Warner Electric SFPBC-500, SFPBC-650 User Manual

Page 12

12

Warner Electric • 800-825-9050

P-202-01 • 819-0482

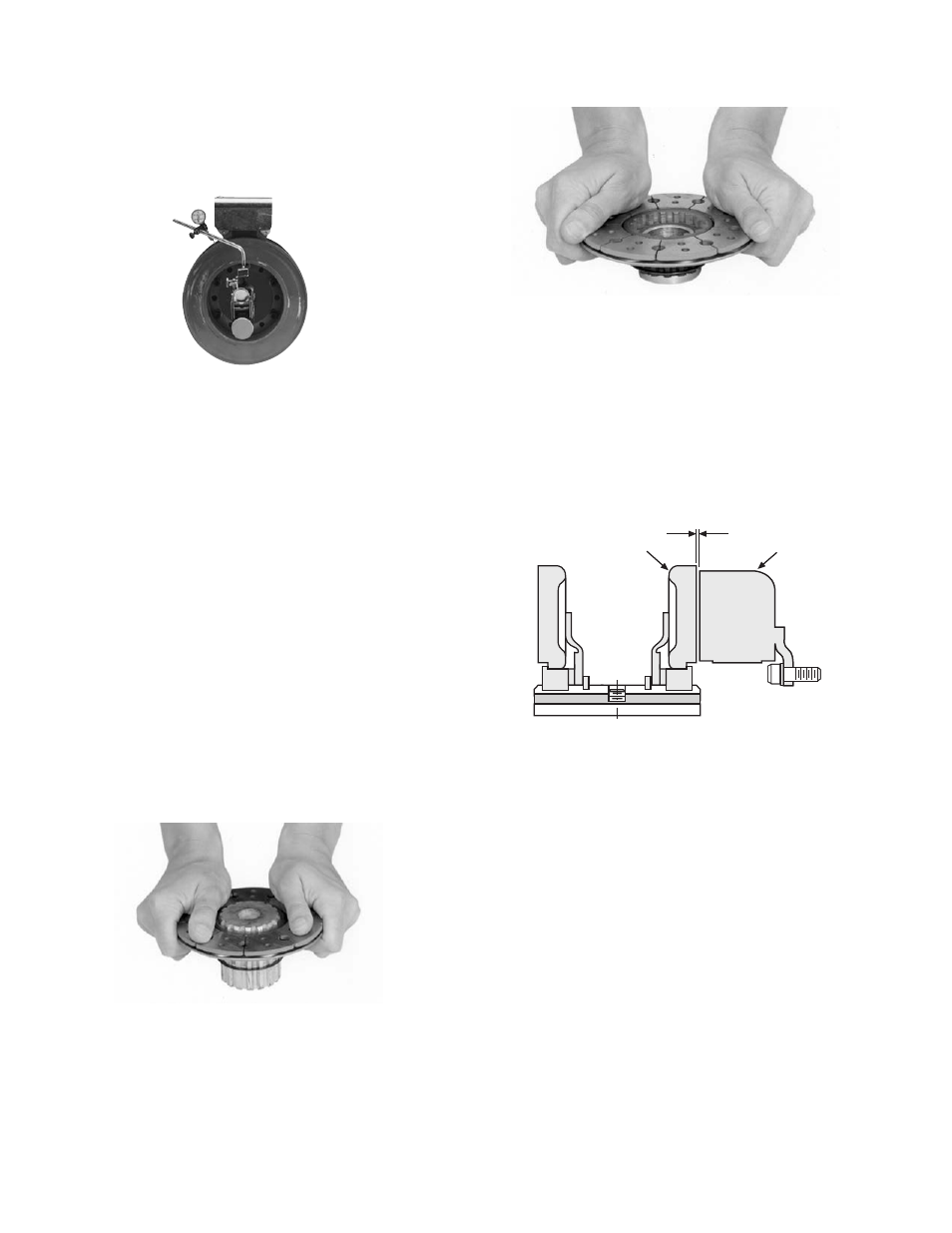

Figure 6

4.

Use a dial indicator to check the unit for

con cen tric i ty and squareness to the

shaft. The unit should be concentric within

.010 T.I.R. and square within .006 T.I.R. (Figure

4)

D. Assembling the Hub and Armatures

The heavy duty units contain spline drive armatures

and hubs. The armatures are shipped with a built-in

autogap spring accessory. This device automatically

maintains a gap of about 1/32'' between the armature

and magnet faces for the life of the unit.

Use the following method to assemble the armature

and splined hub:

1.

Place the armature hub up on one end.

2.

Check the detent ring in the armature

assembly to make sure it is evenly centered

around the spline. This ring moves freely, and

it should be centered for eas i er assembly of

the hub.

3.

Holding one of the armatures with the

segmented side up, press the armature on to

the hub using firm back-and-forth pressure.

(Figure 5)

4.

Push the assembly up against the retainer

ring.

Figure 4

5.

Turn the hub over and repeat Steps 3 and 4

with the other armature. (Figure 6)

E. Mounting the Armature-Hub Assembly

1.

Insert a key in the keyway of the hub and

slide the armature-hub assembly on to the

shaft.

2.

Position the assembly so that the face of the

ar ma ture is about 1/32-inch from the magnet

face. (Figure 7)

3.

Secure the armature-hub assembly in this

position by tightening the two setscrews in

the hub.

4.

Check the assembly by pressing the armature

into contact with the magnet face and then

Figure 5

1/32 inch Gap

Magnet

Armature

Figure 7