Installation and noise prevention, 1 installation environment, 2 supply power – IAI America PDR-101-MW User Manual

Page 19: 3 noise prevention and grounding

9

3. Installation and Noise Prevention

Please pay attention to the controller’s installation environment.

3.1 Installation

Environment

a. Avoid blocking air vents for cooling when installing and wiring the controller. (Insufficient ventilation

prevents the controller from achieving full performance and may also cause failure.)

b. Prevent foreign objects from entering the controller through the air vents. Moreover, be aware that the

controller is neither dust-proof nor water (or oil)-proof; avoid using it in dusty environments or

locations where oil mist and cutting fluid may be scattered.

c. Avoid subjecting the controller to heat radiation from large heat sources such as direct sunlight or

heat-treatment furnaces.

d. Use the controller in an environment with an ambient temperature of 0 to 40

°C and a humidity of 85%

or less (no condensation), and free from corrosive or flammable gases.

e. Use the controller in an environment free from external vibration and impact.

f. Avoid inducing electric noise to the controller unit and wiring cables.

3.2 Supply

Power

Depending on the type of controller, it is possible to select the supply power from 100 VAC or 200 VAC.

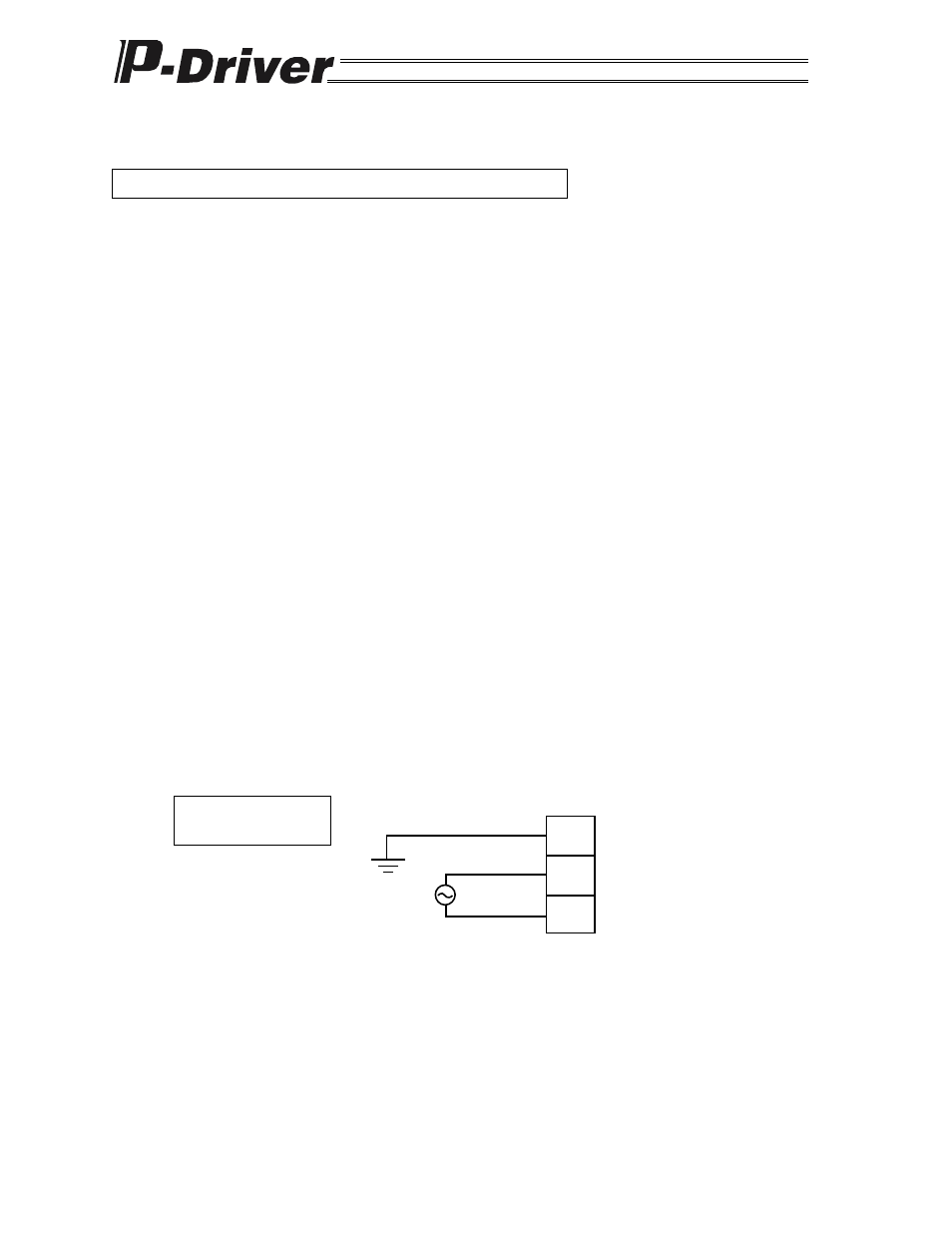

3.3 Noise Prevention and Grounding

(1) Wire and Power Supply

Power-supply terminal block PE is protective ground; perform D-class (third-class) grounding.

Moreover, use electric wires with a thickness of 0.75 mm

2

(AWG18) or more, and thicker than the AC

power-supply wire used.

1

2

3

PE

N

L

D-class grounding

(protective ground)

Power supply 100/200 VAC