Ransburg, Troubleshooting guide (cont.), Evolver 303 robotic atomizers - maintenance – Ransburg Evolver 303 Solvent Applicator A11976-XXX User Manual

Page 53

TROUBLESHOOTING GUIDE (Cont.)

Note: To check for fluid leaks, it is easiest to first remove the applicator from the test station and re-

move the shroud from the applicator. Then the applicator can be remounted to the test station. Leak

detector may be used at all appropriate sources. Be certain to wipe off all residual solution using a

non-conductive solvent such as Naphtha.

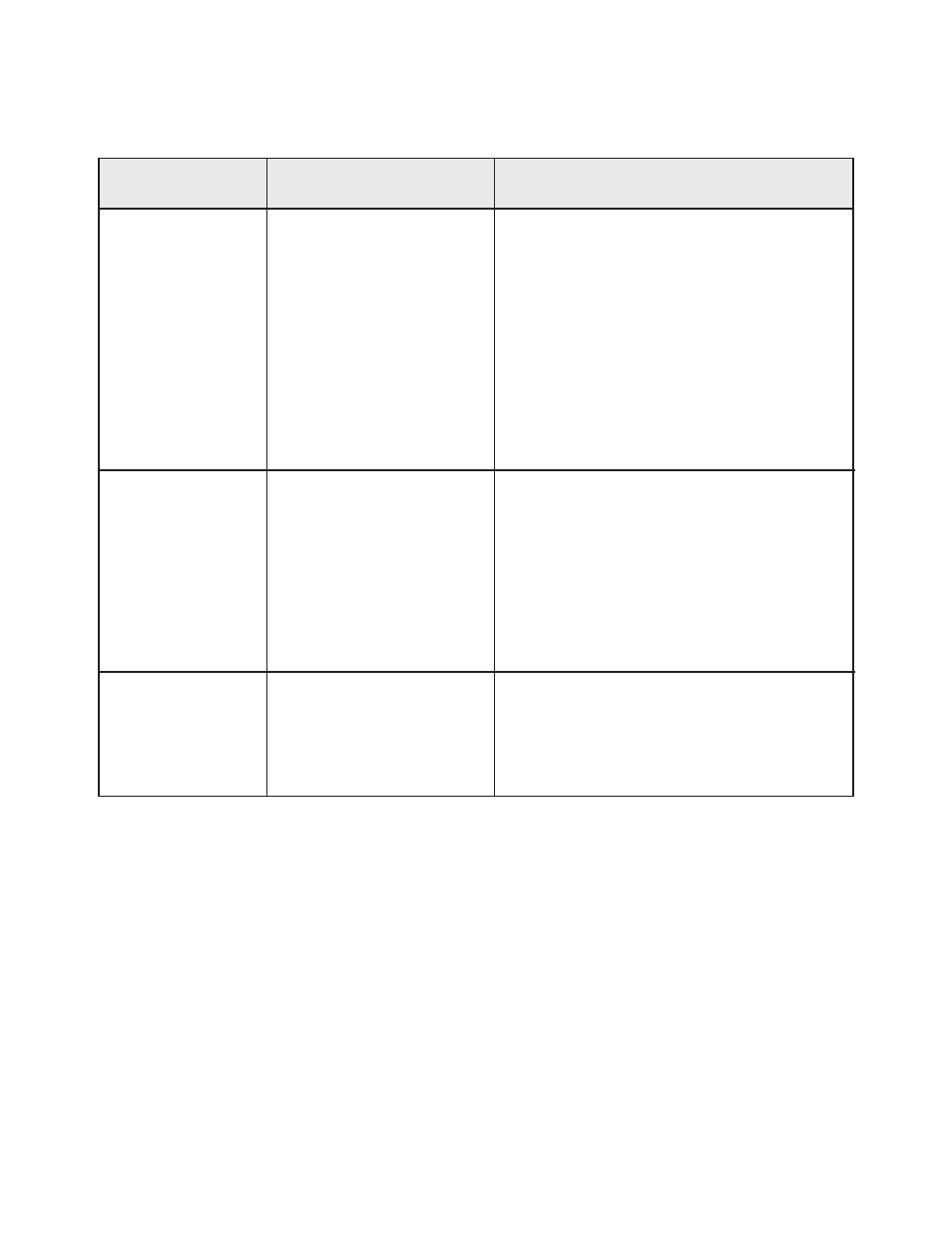

General Problem

Possible Causes

Corrective Action

5. Faulty low voltage connec-

tions (usually indicated by

MicroPak feedback fault

light)

6. Faulty high voltage connec-

tion

7. MicroPak or cascade failure

8. Improper color change (i.e.

paint or solvent in dump line)

1. Low or no high voltage

2. Poor grounding of parts

being coated

3. Excessive target distance

1. Applicator mounting nut is

loose

2. O-ring is missing

3. O-ring is damaged

5. a. Make sure quick disconnection electrical

connection is aligned and clean.

b.Check low voltage connection at cascade.

6. Remove cascade and check continuity be-

tween cascade connection and turbine shaft.

7. Refer to "MicroPak" service manual for de-

tailed "Troubleshooting Guide".

8. Optimize color change.

1. Verify high voltage at bell cup edge. Normally,

a high voltage setting of 70 -100 kV is

appropriate for most applications.

2. Verify that parts being coated are properly

grounded (the electrical resistance between

the part and ground must not exceed 1 megohm).

3. The recommended target distance is between

10-14-inches (.25m-.36m) (see "Target Dis-

tance" in the "Operation" section of this

manual).

1. Tighten mounting ring.

2. Install o-ring.

3. Visually inspect for damage and replace.

Low or No High

Voltage (Cont.)

Low Transfer

Efficiency (or light

coverage)

Fluid and/or Air

Leakage Between

the Robot and Rear

Manifold Plates

50

Evolver 303 Robotic Atomizers - Maintenance

Ransburg

AA-07-03.2