Ransburg, Valve and seat inspection, Evolver 303 robotic atomizers - maintenance – Ransburg Evolver 303 Solvent Applicator A11976-XXX User Manual

Page 48

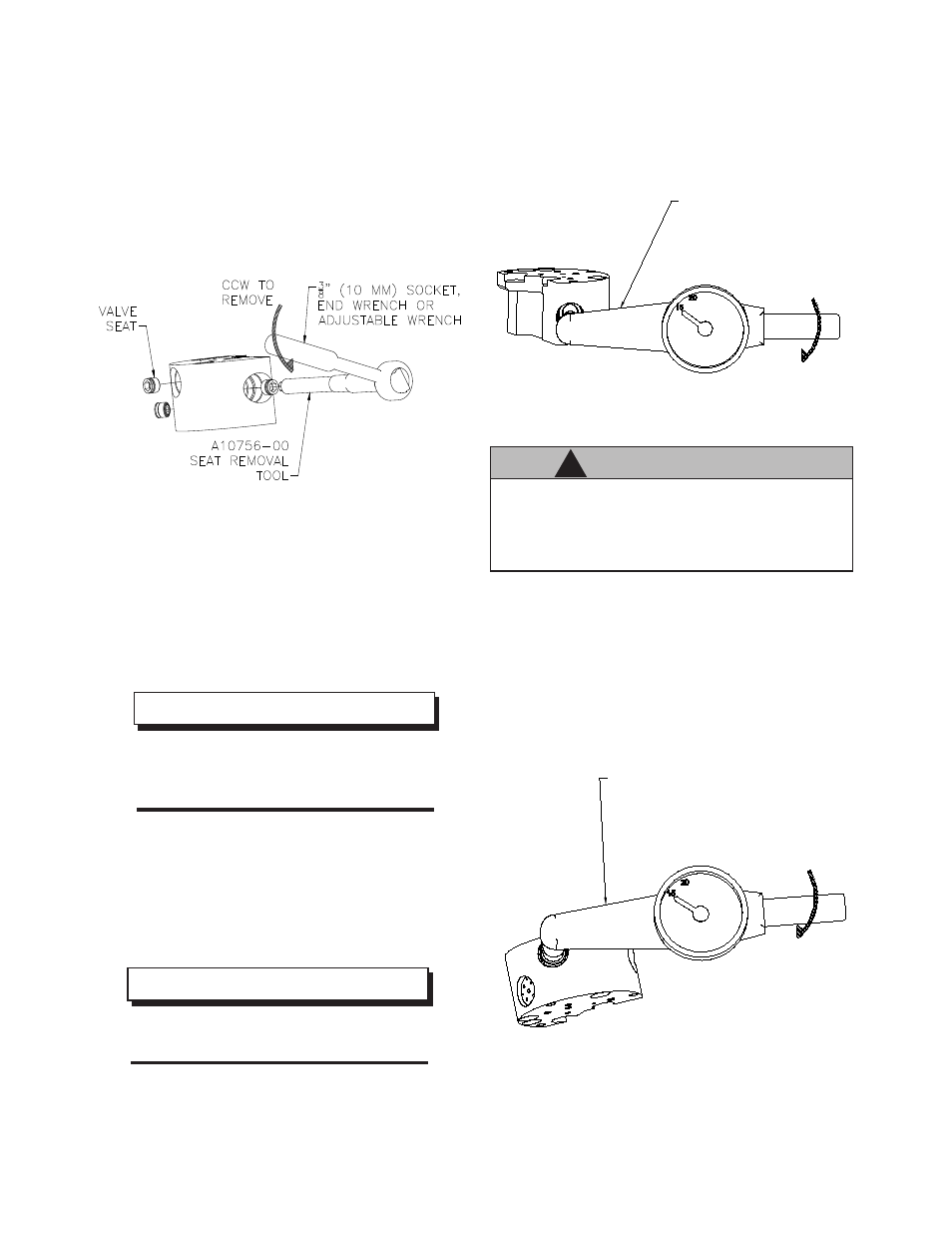

Figue 18: Seat Removal

Using the seat removal tool (A10756-00), insert

the smaller hex end into the block to engage the

seat female hex. Using a 3/8" (10mm) socket

end-wrench, or adjustable wrench, remove the

seat by turning counter-clockwise, as shown in

Figure 18.

Valve and Seat Inspection

Inspect the valves and seats for any build-up of

materials. Valves should be cleaned with an ap-

propriate cleaning solvent to remove the material

on it.

>

A seat should not be replaced unless

there are indications of valve leakage in

operation.

NOTE

Replacement

Lubricate the seat o-ring using a suitable lubricant.

By hand, using the seat tool (A10756-00), carefully

start the seat into the pocket for the seat.

Hand tighten the seat in place. Using a torque

wrench with a 3/8" (10mm) socket, torque the

valve seats to 15-20 lbs•in (1.2.3 Nm)

Figure 19: Valve Seat Torque

>

Carefully start the seat into the pocket.

It may be easily cross threaded.

NOTE

>

Always use a torque wrench to torque the

seats in place. Over-torquing the seats may

cause permanent irrepairable damage to the

rear manifold.

C A U T I O N

!

Lubricate the valve o-rings with a suitable o-ring

lubricant. By hand, start the threads clockwise

of the valve into the pocket. Tighten using a 1/2"

(13mm) socket and torque to 15-20 lbs•in (1.7-

2.3 Nm).

Figure 20: Valve Torque

CW TO

TIGHTEN

15-20 LBS-IN

(1.7-2.3 N-M)

TORQUE

WRENCH

CW TO

TIGHTEN

15-20 LBS-IN

(1.7-2.3 N-M)

TORQUE WRENCH

45

Evolver 303 Robotic Atomizers - Maintenance

Ransburg

AA-07-03.2