4 sampling – Teledyne 7500ZA - Infrared Gas Analyzer User Manual

Page 28

Installation Model

7500ZA

Teledyne Analytical Instruments

12

3.4 Sampling

3.4.1 Sample Gas Conditioning

1. Dust from the sampling gas should be completely removed using

a filter. For the final stage filter, use a filter that removes dust

particles down to 0.3µm.

2. Dew point must be lower than the ambient temperature. If vapor

is contained in the sample, dew point should be lowered to 2°C

using a dehumidifier.

3. If SO

3

mist is present in the sample gas, use a mist filter or

cooler to remove the SO

3

mist. Other mists should be removed

using a mist filter or gas dryer.

4. Corrosive gases such as Cl

2

, F

2

and HCl, if present in

considerable amounts, will shorten the life of component parts.

5. Sample gas temperature should be within 0 to 50°C. Do not flow

hot gas directly into the instrument.

3.4.2 Sample Gas Flow

Sample flow should be 0.5L/min ± 0.2L/min. Avoid any flow

fluctuation during measurement. Observe the flow reading using the

flowmeter provided as shown in the example of the sampling system

configuration (Item 3.4.6).

3.4.3 Preparation of Standard Gas

Routine calibration is required once a week using span and zero

calibration gases to keep the instrument performing optimally. Prepare a

standard gas cylinder for zero calibration and span calibration per the

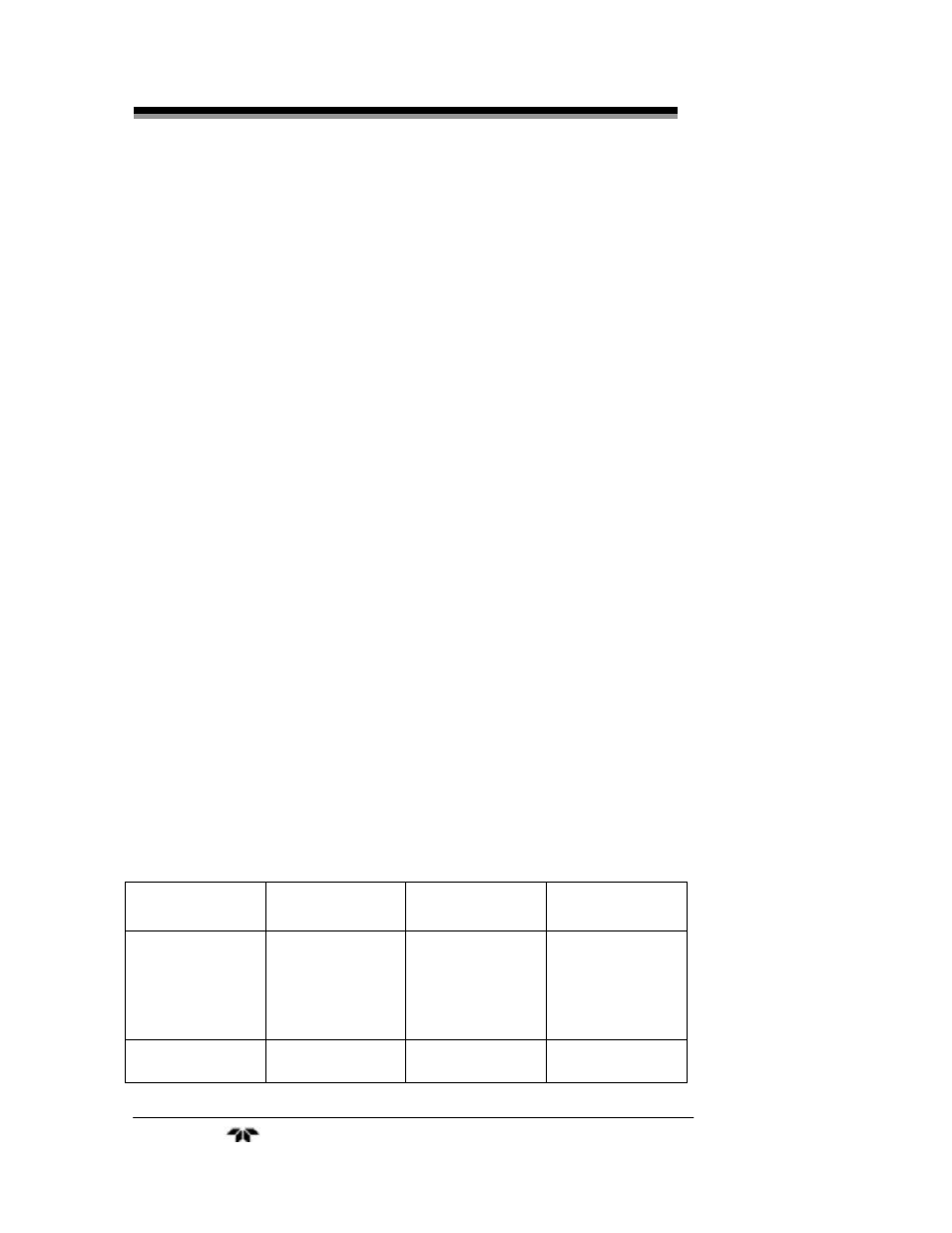

table below.

Without

O

2

Sensor

Built-in O

2

Sensor

External O

2

Sensor

Zero Gas

N

2

N

2

(O

2

of 99.9 to 100

vol% for reverse

range O

2

measurement.)

Dry air

Span gas other

than for O

2

Gas with

concentration

Gas with

concentration of

Gas with

concentration of