Maintenance and cleaning, Rotor replacement procedure, H-dimensions – GF Signet 2537 Paddlewheel Flow Sensor User Manual

Page 14

14

Signet 2537 Flowmeter

Maintenance and Cleaning

The 2537 requires very little maintenance.

• If the paddlewheel becomes fouled, it can be cleaned with mild detergents and a small brush.

• The electronics portion of the 2537 does not require maintenance or cleaning.

Rotor Replacement Procedure

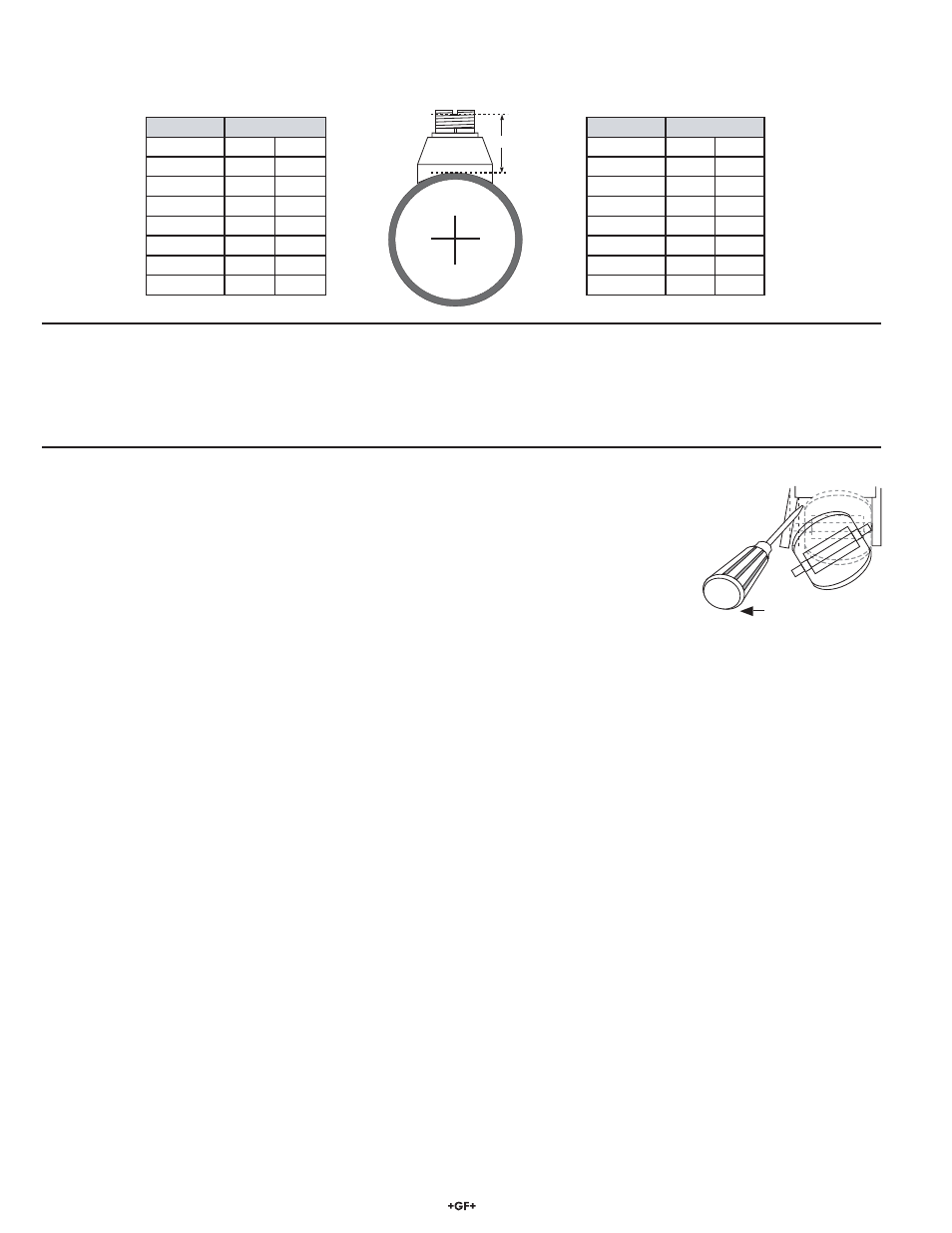

1. To remove the rotor, insert a small screwdriver between the rotor and the ear of the sensor.

2. Twist the screwdriver blade to À ex the ear outward enough to remove one end of the rotor and pin.

DO NOT À ex the ear any more than necessary! If it breaks, the sensor cannot be repaired.

3. Install the new rotor by inserting one tip of the pin into the hole, then carefully À ex the opposite ear

back enough to slip rotor into place.

H-Dimensions

The plastic insert in Weldolet ¿ ttings MUST be removed during the welding process. When reinstalled, it is important that the insert be

threaded to the proper height ("H" dimension).

Weldolet

“H” dimension

Part number

inches

mm

CS4W020

2.38

60.45

CS4W025

2.33

59.18

CS4W030

2.32

58.92

CS4W040

2.30

58.42

CS4W050

3.09

78.48

CS4W060

2.96

75.18

CS4W080

2.73

69.34

"H"

Weldolet

“H” dimension

Part number

inches

mm

CR4W020

2.38

60.45

CR4W025

2.33

59.18

CR4W030

2.32

58.92

CR4W040

2.30

58.42

CR4W050

3.09

78.48

CR4W060

2.96

75.18

CR4W080

2.73

69.34