Maintenance, Hot-tap sensor removal – GF Signet 2540 Stainless Steel High Performance Flow Sensor User Manual

Page 7

2540 High Performance Flow Sensor

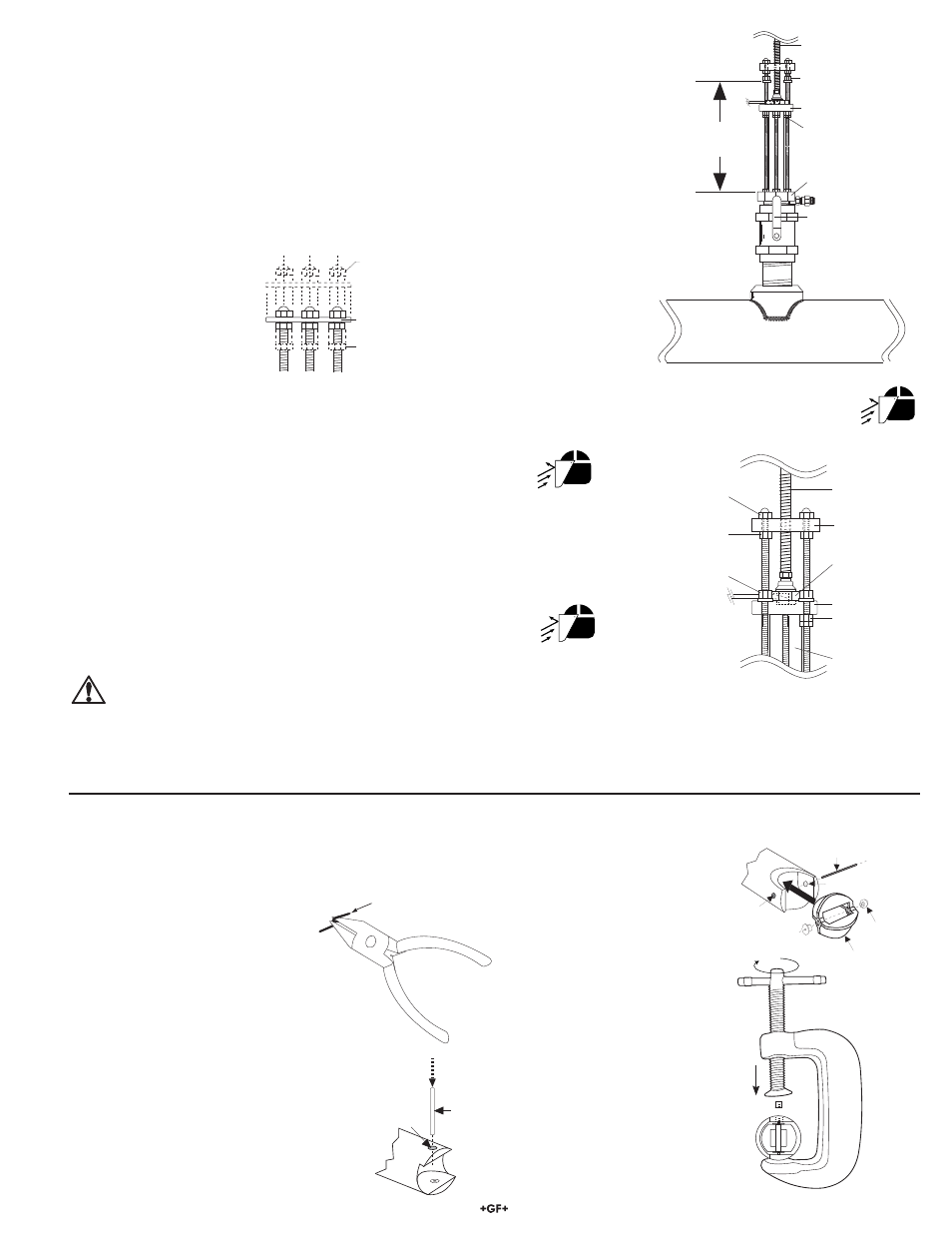

7

D. Wearing safety face protection, loosen the upper hex nuts and raise to 372 mm (14.6 in.) from top of sensor fi tting to

bottom of upper hex nuts/lock washers. CAUTION! This measurement is critical to maintain watertight seal in

sensor while allowing clearance to close the isolation valve.

E. Wearing safety face protection, turn the installation tool shaft

counterclockwise to withdraw sensor until the sensor fl ange contacts

the upper hex nuts. (Fig. 18)

F. Raise

one lower hex and jam nut to bottom of sensor fl ange.

G. Close isolation valve, remove bearing plate and tool.

H. Wearing safety face protection, cover the bleed valve with suitable

protection (rag, towel, etc.) and open the bleed valve (ccw rotation)

to relieve internal pressure. Pull sensor up until bleed valve purges

some fl uid (indicating sensor is past 1st o-ring seal inside sensor

fi tting).

CAUTION: In case of a leaky isolation valve, the sensor will be under a slight

amount of pressure. Care should be taken when removing the sensor.

Use the bleed valve to relieve this pressure taking care not to spray fl uid on yourself or others.

Sensor can now be safely removed. When reinstalling the sensor: leave one lower hex nut in position to guide sensor to proper

isolation valve clearance height before opening isolation valve. Return to "H" dimension height after valve is opened.

installation tool

threaded shaft

sensor flange

cap nuts

upper hex nuts

1 lower hex nut

and jam nut

sensor body

installation tool

bearing plate

protector plate

hex nuts

swivel mount

w/cable port

Fig. 18

8. Maintenance

Your sensor requires little or no maintenance of any kind, with the exception of an occasional sensor/paddlewheel cleaning.

protector plate

hex nut

protector plate

cap nuts

protector plate

Fig. 16

installation tool

threaded shaft

process pipe (side view)

372 mm

(14.6 in.)

upper hex nuts

and lock washers

sensor flange

lower hex and

jam nuts

UNDER PRESSURE!

sensor fitting

isolation valve

Fig. 17

7. Hot-Tap Sensor Removal

To remove the Hot-Tap sensor safely from a pressurized active pipe, the entire installation

process must be reversed.

A. Remove the cap nuts, protector plate and protector plate hex nuts. (Fig. 16)

B. Thread installation tool in place and secure bearing plate in place of sensor protector plate.

(Fig. 17)

C. Turn shaft of installation tool clockwise to lower tool into opening in sensor fl ange. Guide

cable into the port to prevent damage.

Rotor Replacement Procedure

1. With a small pair of needle-nose

pliers, fi rmly grip the center of the

rotor pin (axle) and with a twisting

motion, bend the rotor pin into an

"S" shape. This should pull the

ends of the pin out of the retainers

and free the rotor assembly.

2. Remove retainer from each side by

gently tapping it inwards using a punch.

Install a new retainer with its rotor pin

clearance hole inward. Only install one

retainer at this time.

Punch

Retainer

Rotor Pin

Rotor Pin

Existing

Retainer

New

Bearings

Rotor

Assembly

3. Insert the new rotor assembly

and bearings into the rotor

housing of the sensor and

place the new rotor pin (axle)

through the open end of

the rotor housing, through

the rotor and bearings, and

into the previously installed

retainer.

4. Using a vise or C-clamp, press

the second retainer into the hole

in the sensor body while lining

up the rotor pin with the center

of the retainer hole.

Note: A hammer and center

punch can also be used if a

clamp or vise is not available.