Pipe wall thickness: __________ pipe i.d – GF Signet 2540 Stainless Steel High Performance Flow Sensor User Manual

Page 4

2540 High Performance Flow Sensor

4

"H"

alignment rod

sensor flange

process pipe

direction

of flow

pipe side view

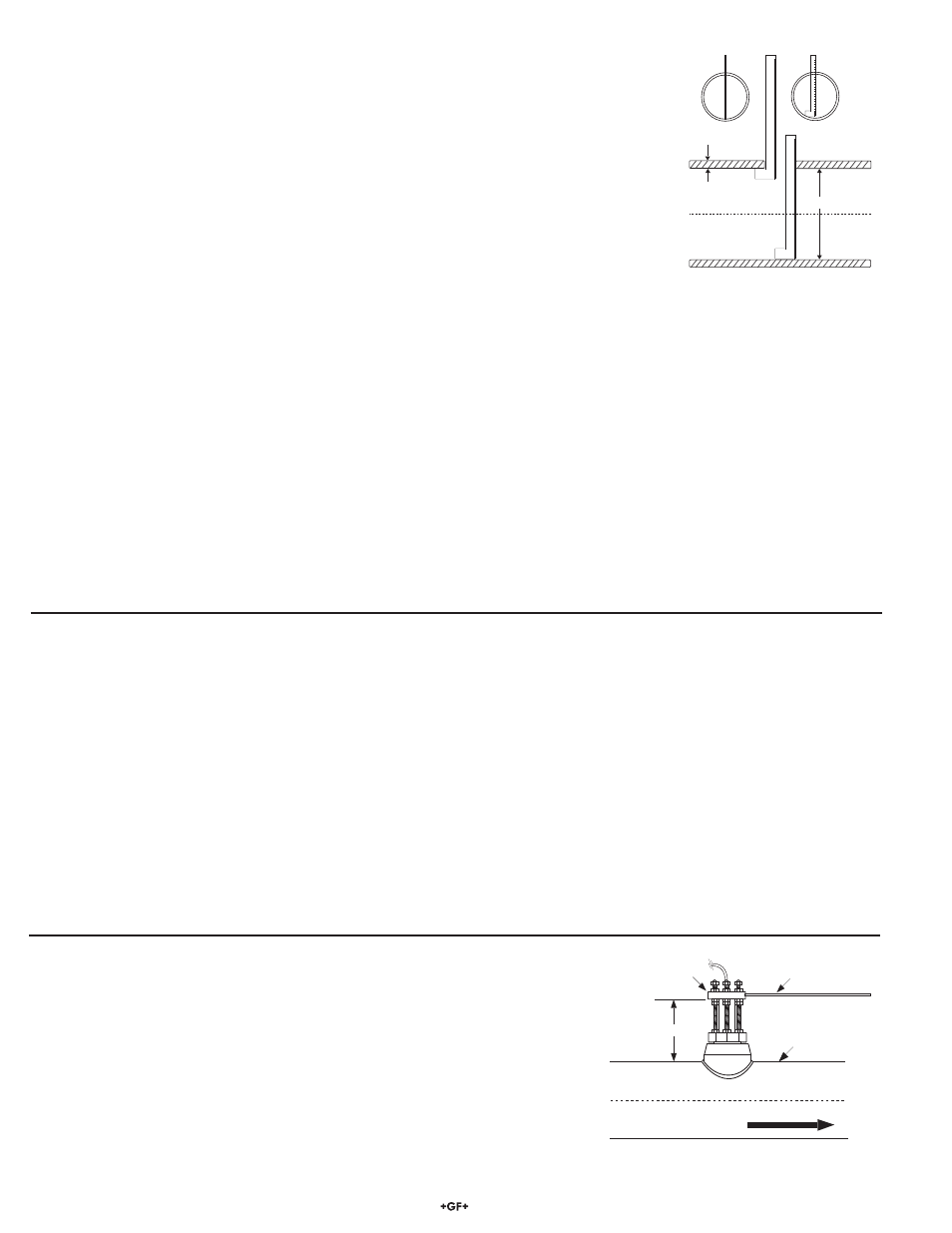

5.5 Calculating the H Dimension

Before installing the sensor some critical dimensions must be established (for Hot-Tap installations,

we assume the pipe dimensions are known). The rotor shaft must be located 10% inside the pipe I.D.

to ensure accurate calibration capability. To accomplish this, the "H" dimension is measured from the

outside surface of the pipe to the bottom of the sensor fl ange.

Nominal "H" dimensions for standard pipes are listed here. For non-standard pipe dimensions, calculate

the "H" dimension using the formula listed below. The wall thickness and inside diameter (I.D.) are

required for the "H" dimension calculation.

The 6 inch ruler (included) may be used to measure your pipe I.D. and wall thickness up to 5 inches

(standard sensors only).

Pipe wall thickness: __________

Pipe I.D.: ___________

A

B

1

2

3

4

5

6

1

2

3

4

5

A

B

1

2

3

4

5

6

1

2

3

4

5

pipe I.D.

wall

thickness

A

B

1

2

3

4

5

6

1

2

3

4

5

incorrect

correct

H Dimensions, Standard Sensors (2540-1, 2540-2)

Wrought Steel Pipe Per ANSI 36.10

NPS

SCH 40

SCH 80

STD

XS

inches

inches inches inches inches

1½

4.924 4.880 4.924 4.880

2

4.869 4.818 4.869 4.818

2½

4.780 4.722 4.780 4.722

3

4.707 4.640 4.707 4.640

3½

4.649 4.576 4.649 4.576

4

4.590 4.510 4.590 4.510

5

4.467 4.374 4.467 4.374

6

4.344 4.222 4.344 4.222

8

4.110

3.968

4.110

3.968

10

3.863 3.680 3.863 3.755

12

3.630 3.405 3.655 3.555

14

3.480 3.230 3.530 3.430

16

3.230 2.955 3.330 3.230

18

2.980 2.680 3.130 3.030

20

2.755 2.405 2.930 2.830

22

-----

2.130 2.730 2.630

24

2.280 1.855 2.530 2.430

Stainless Steel Pipe Per ANSI B36.19

NPS

SCH 5S

SCH 10S

SCH 40S

SCH 80S

inches inches inches

inches

inches

1½

4.988

4.953

4.924

4.880

2

4.940

4.905

4.869

4.818

2½

4.876

4.847

4.780

4.722

3

4.814

4.784

4.707

4.640

3½

4.764

4.734

4.649

4.576

4

4.714

4.684

4.590

4.510

5

4.586

4.567

4.467

4.374

6

4.480

4.460

4.344

4.222

8

4.280

4.249

4.110

3.968

10

4.048

4.023

3.863

3.755

12

3.830

3.811

3.655

3.555

14

3.705

3.680

-----

-----

16

3.498

3.480

-----

-----

18

3.298

3.280

-----

-----

20

3.080

3.056

-----

-----

22

2.880

2.856

-----

-----

24

2.656

2.630

-----

-----

Wrought Steel Pipe Per ANSI 36.10

NPS

SCH 40

SCH 80

STD

XS

inches inches

inches

inches

inches

1 ½

15.084

15.040

15.084

15.040

2

15.029

14.978

15.029

14.978

2 ½

14.940

14.882

14.940

14.882

3

14.867

14.800

14.867

14.800

3½

14.809

14.736

14.809

14.736

4

14.750

14.670

14.750

14.670

5

14.627

14.534

14.627

14.534

6

14.534

14.382

14.534

14.382

8

14.270

14.128

14.270

14.128

10

14.023

13.840

14.023

13.915

12

13.790

13.565

13.815

13.715

14

13.640

13.390

13.690

13.590

16

13.390

13.115

13.490

13.390

18

13.140

12.840

13.290

13.190

20

12.915

12.565

13.090

12.990

22

-----

12.290

12.890

12.790

24

12.440

12.015

12.690

12.590

Stainless Steel Pipe Per ANSI B36.19

NPS

SCH 5S

SCH 10S

SCH 40S

SCH 80S

inches inches inches inches inches

1 ½

15.148

15.113

15.084

15.040

2

15.101

15.065

15.029

14.978

2 ½

15.036

15.007

14.940

14.882

3

14.974

14.944

14.867

14.800

3 ½

14.924

14.894

14.809

14.736

4

14.874

14.844

14.750

14.670

5

14.747

14.727

14.627

14.534

6

14.640

14.620

14.534

14.382

8

14.440

14.409

14.270

14.128

10

14.208

14.183

14.023

13.915

12

13.990

13.971

13.815

13.715

14

13.865

13.840

-----

-----

16

13.658

13.640

-----

-----

18

13.458

13.440

-----

-----

20

13.240

13.216

-----

-----

22

13.040

13.016

-----

-----

24

12.816

12.790

-----

-----

(-----) unavailable

(-----) unavailable

Standard Sensors: H = 5.23 - wall thickness - (0.10 x I.D.)

Hot-Tap Sensors: H=15.39 in. - wall thickness - (0.10 x I.D.)

Example: 3.0 inch schedule 80 wrought steel

Wall thickness = 0.3 in. / Inside diameter = 2.9 in.

H = 5.23 - 0.3 - (0.10 X 2.9) / H = 117.86 mm (4.64 in.)

Record your sensor's "H" dimension for future reference:

H= ___________

After correct dimensions are calculated and recorded, the sensor can be installed in the

fi tting. The Standard and Hot-Tap versions require substantially different procedures.

H Dimensions, Hot-Tap Sensors (2540-3, 2540-4)