Installation onto the pipe, Danger – Burkert Type 8045 User Manual

Page 22

18

Installationandcommissioning

7.2.

Installation onto the pipe

danger

risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the pipe before loosening the process connections.

risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and safety relating to the use of aggressive fluids.

The 8045 flowmeter has to be inserted into an S020 fitting mounted on a pipe.

7.2.1.

recommandations for installing the 8045 on the pipe

→

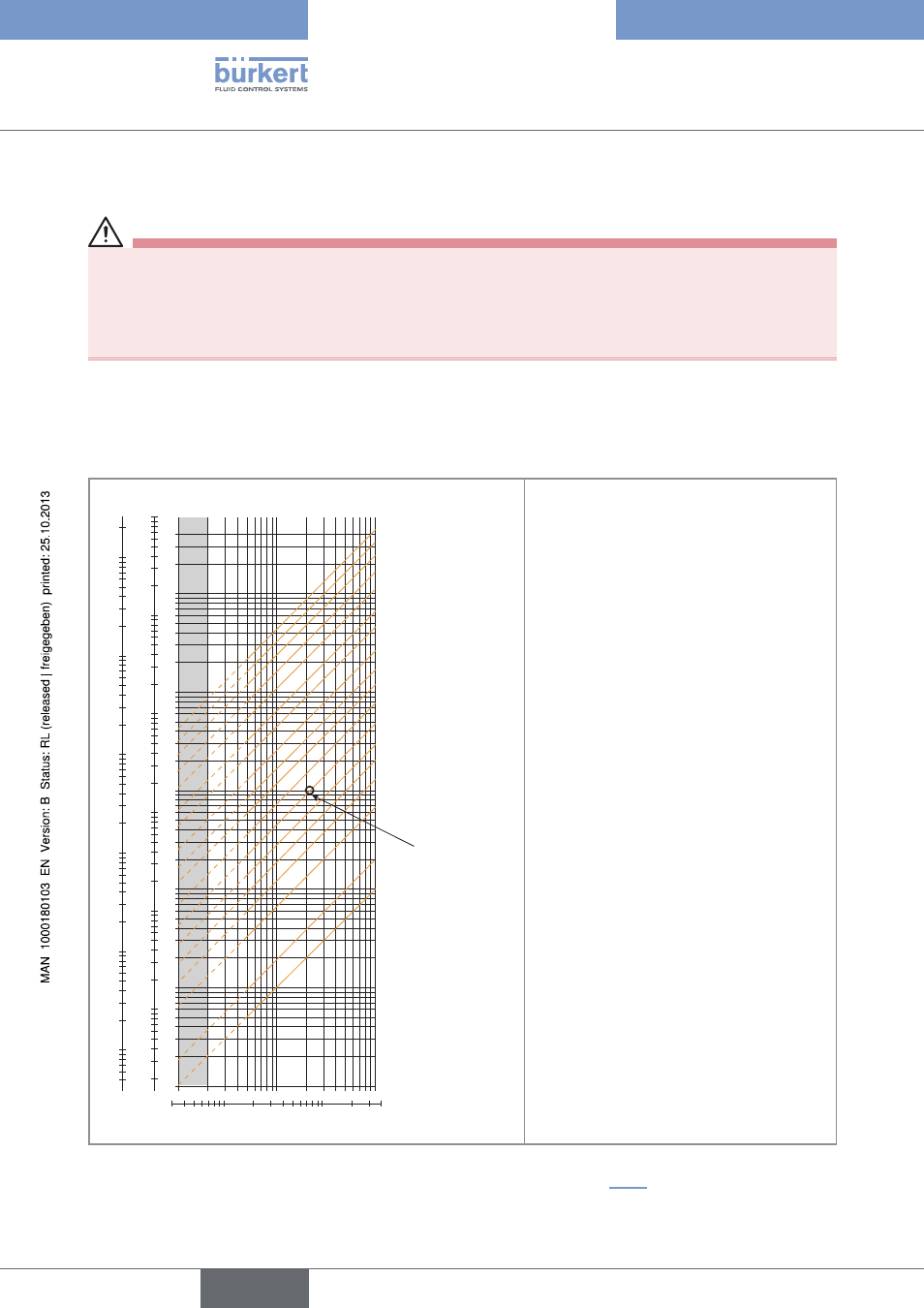

Choose an S020 fitting appropriate to the velocity of the fluid inside the pipe: refer to the graphs below:

0.1

0.3 0.5

1

3

5

10

0.01

0.02

0.05

0.1

0.2

0.5

1

2

5

10

20

50

100

200

m

3

/h

0.2

0.5

1

2

5

10

20

50

100

200

500

1000

2000

3000

l/min

0.3 0.5

1

3

5

10

30

m/s

fps

US gpm

0.05

0.1

0.2

0.5

1

2

5

10

20

50

100

200

500

1000

DN 65 (DN80)*

DN 50 (DN65)*

DN 40 (DN50)*

DN 32 (DN40)*

DN 25 (DN32)*

DN 20 (DN25)*

DN 15 (DN15 / DN20)*

500

1000

2000

2000

5000

10000

5000

20000

5000

10000

20000

30000

50000

100000

DN 400

DN 350

DN 300

DN 250

DN 200

DN 150

DN 125

DN 100

DN 80 (DN100)*

DN 6

DN 8

Example

Flow rate

Fluid velocity

Example:

• Specification: if the nominal flow rate is

10 m

3

/h, the ideal flow velocity is between

2 and 3 m/s.

• Solution: intersection between flow rate and

flow velocity in the graph gives the appro-

priate pipe diameter, DN40 (or DN50 for

the asterisked fittings).

* For the fittings:

• with external thread connections acc. to

SMS 1145,

• with welding end connections acc. to

SMS 3008, BS 4825 / ASME BPE or

DIN 11850 Rg 2,

• with Clamp connections acc.

to SMS 3017 / ISO 2852,

BS 4825 / ASME BPE or DIN 32676.

→

Install the device on the pipe in such a way that the upstream and downstream distances are respected

according to the design of the pipes, refer to standard EN ISO 5167-1 and Fig. 7 :

English

Type 8045