Burkert Type 3004 User Manual

Page 11

11

Installation

Procedure:

Fig. 6:

Standard installation

→

Ensure that the ball valve / the flap valve is in its closed position.

→

Carefully connect the rotary actuator to the shaft of the ball valve

/ flap valve.

When connecting the rotary actuator, ensure that it is not

twisted and that the fastening threads of the rotary actuator

are covered by the fastening bores of the ball valve / flap valve.

→

Screw the fastening screws into the fastening threads of the rotary

actuator and tighten them firmly (max. 3 Nm).

7.2.2. Set mechanical end position limit

(actuators 100 - 300 Nm)

The mechanical end position limits have been preset at the

factory and glued on with Loctite. However, they can be

adjusted by turning the screws M8 (pos. 17, see “Fig. 2”).

Then the nuts must be glued on again.

→

Loosen the M8 nuts on the mechanical limit stops (pos. 17, “Fig.

2”) and adjust the mechanical end position limits.

→

Glue nuts on again with Loctite (e.g. Loctite 577).

7.2.3. Adjusting limit switch contacts

The two upper limit switch contacts have been set to

0 – 90° at the factory.

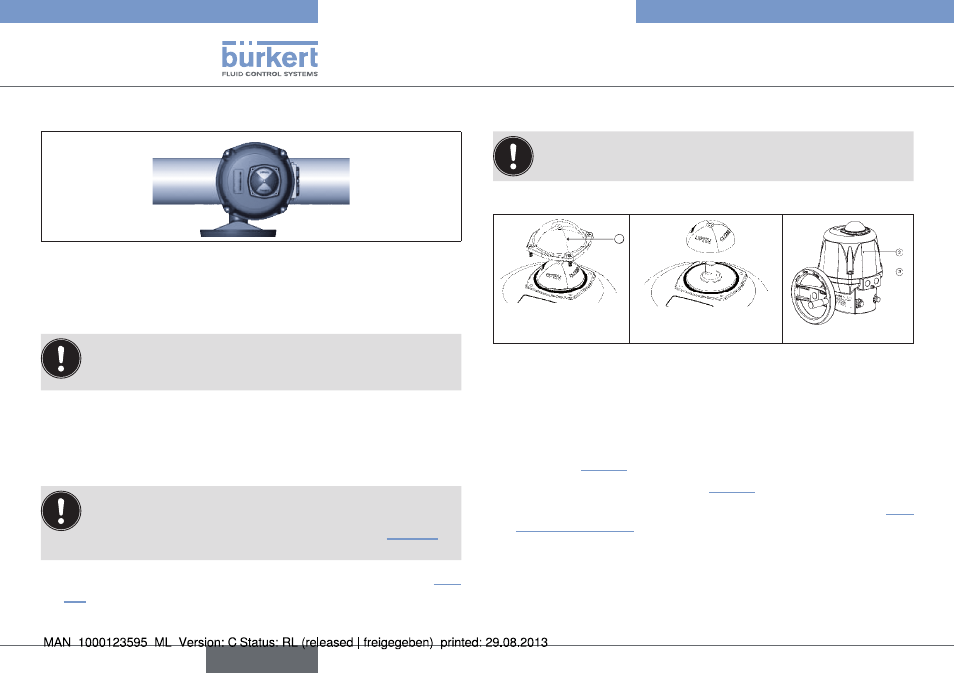

Removing position indicator and hood

1

Fig. 7:

Removing

glass hood

Fig. 8:

Removing

position indicator

Fig. 9:

Removing

hood

Procedure:

→

Remove glass hood of the position indicator 1 including the sealing

ring by loosening the four fastening screws and remove the glass

hood (see “Fig. 7”).

→

Remove position indicator (see “Fig. 8”).

→

Remove hood 2 by loosening the four fastening screws 3 (see “Fig.

9: Removing hood”).

english

Type 3004